Remcor Technology is one of professional laser welding machine suppliers for laser solutions and operates a sophisticated laser machine factory .which offers the most advanced manufacturing technology in the industry, specializing in all types of manufacturing technology for metals, aluminum, ferrous and none ferrous material fabrication. which have got high appreciations from the global customers.

The 3 in 1 fiber laser cutting welding and cleaning machine applies the latest laser technologies. Which integrate the laser cutting welding and cleaning in one system and head. Compared with the traditional welding or cleaning machine, the advantages are quite obvious for laser welding and cleaning application.

Combines laser welding machine, laser cutting machine, and laser cleaning machine into one system and one laser head

Users can easily switch between welding / cutting / cleaning modes based on application needs

Welding speed up to 2 m/min, compared with 0.5 m/min for traditional TIG/MIG welding

3–5 times faster productivity, significantly improving production efficiency

Produces smooth weld seams with no secondary polishing or grinding required

No welding certification required

Operators can achieve high-quality welding and cleaning results after simple practice

Reduces labor costs and eliminates expensive professional training

Plug-and-play design with simple installation

User-friendly control system suitable for beginners

Almost maintenance-free, reducing downtime and service costs

No need for dedicated welding rooms, special equipment, or multiple machines

One 3 in 1 laser welding cleaning machine meets various application requirements

Ideal for workshops, on-site processing, repair, and flexible manufacturing

Simple Installation : Only need to connect the power and gas can get to use.

Integrated Laser source(Max/Raycus laser source) and chiller (Hanli)

Sup laser head, which is the most common laser head , it's stable in using, no maintenance. Light weight and easy to handle.

Sup laser controlling system, which is the best system with it's convinient in using. Support four contries' language. Touch screen, easy and quick to click and set. Can save and copy the technology easily. Simple to handle.

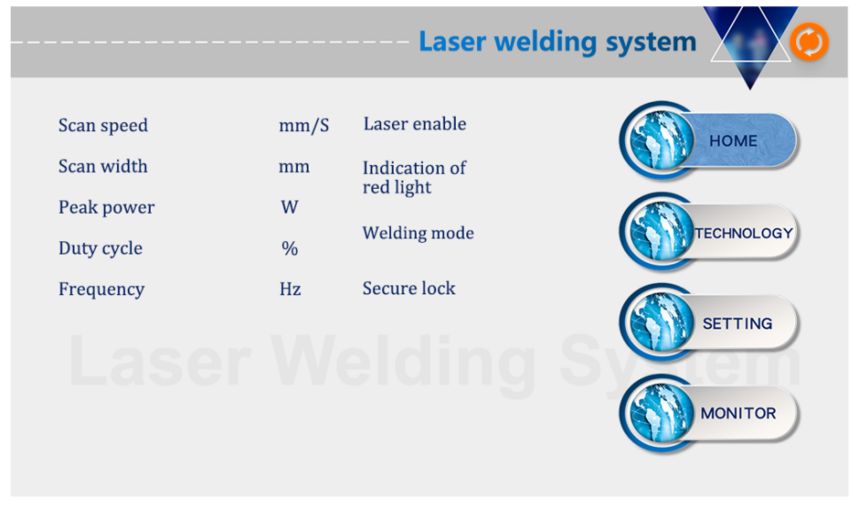

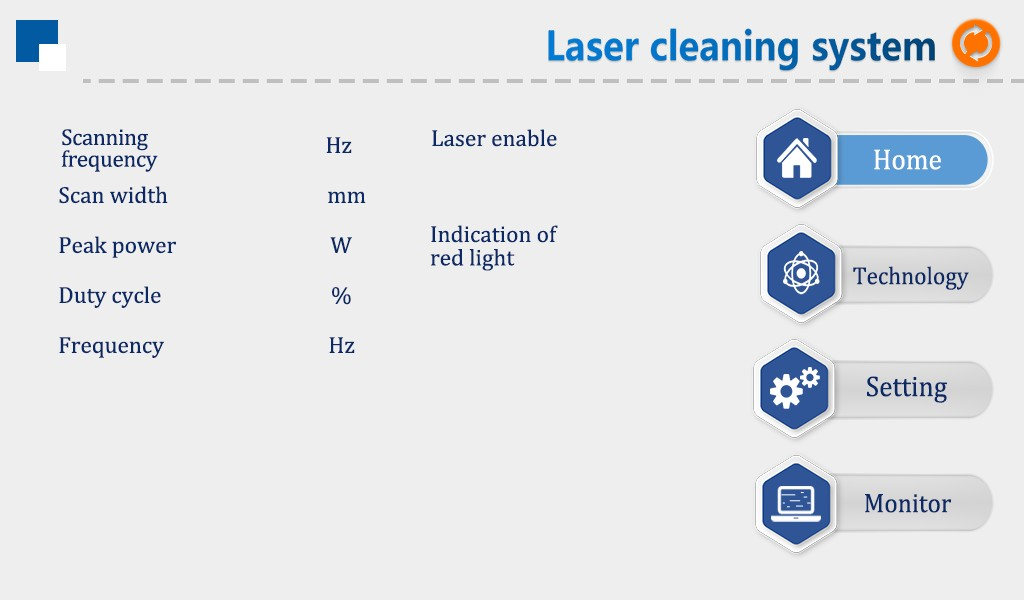

Basic features: The product apply with a self-developed three-in-one control system can be flexibly switched the mode of welding, cleaning, and cutting. It sets up multiple security alarms and can be operated easily and flexibly.

More stability: All parameters are visible and the status of the whole machine will be monitored in real time, so that we can avoid problems in advance and troubleshoot and resolve issues easily to make sure that the system can work stably.

Technical parameters: technical parameters can be set, and various technical effects can be tried flexibly.

Stable parameters and high repeatability: Nozzle Air Pressure and Lens Status are determined, the power of the laser is stable, the craft parameters can be repeatable, which greatly improves efficiency

Laser | Nominal output power | W | 1000/1500/2000/3000 |

Working mode | mm | CW/Modulated | |

Range of laser power | - | 10-100 % | |

Modulation frequency | Hz | 50-5000 | |

Wavelength | nm | 1080 | |

Indicated output power of red light | mW | 0.5-1 | |

Hand-held optical cable length | m | 8-10 | |

Machine Size | Length*Width*Height | mm | 800*530*900 |

Machine Weight | Net | kgs | 200 |

Electricity Supply | Working voltage | - | 220V single phase |

Do not hesitate to give us a call or drop off a message if you have any question.