Thanks to high precision, high speed, and lower costs on gas or labour or maintenance compared with traditional flame or plasma cutting methods. More and more manufacturers choose the laser cutter to process stainless steel plates or tubes. Remcor laser, a professional laser machine distributor, has 18 years of experience in laser equipment manufacturing. We provide the best quality CNC laser cutter for stainless steel at a competitive price.

Looking for a high-quality stainless steel laser cutter for sale? If you need a powerful stainless steel laser cutter for sale, we offer top-tier machines designed for precision and efficiency. Our stainless steel laser cutter for sale is perfect for industrial manufacturing, automotive parts, signage, and metal fabrication. Get the best stainless steel laser cutter for sale today! If you’re searching for a reliable laser cutter for aluminium sheet, you can also contact us.

In the market, high-power laser cutters and coil fed punching machines may be the trend, but the high cost is not acceptable for many customers. So we think the low-power laser cutters are still the main engine in the market and among them, we think 3000w and 6000w are the most popular power in the market. For stainless steel cutting, we need to consider the final application, which as we all know, is mainly applied in kitchens, bathrooms, the construction industry, electric appliances, surgical instruments and some other industries. We can find that most products would be thickness within 20mm. Obviously, it's the normal thickness for fibre laser cutting.

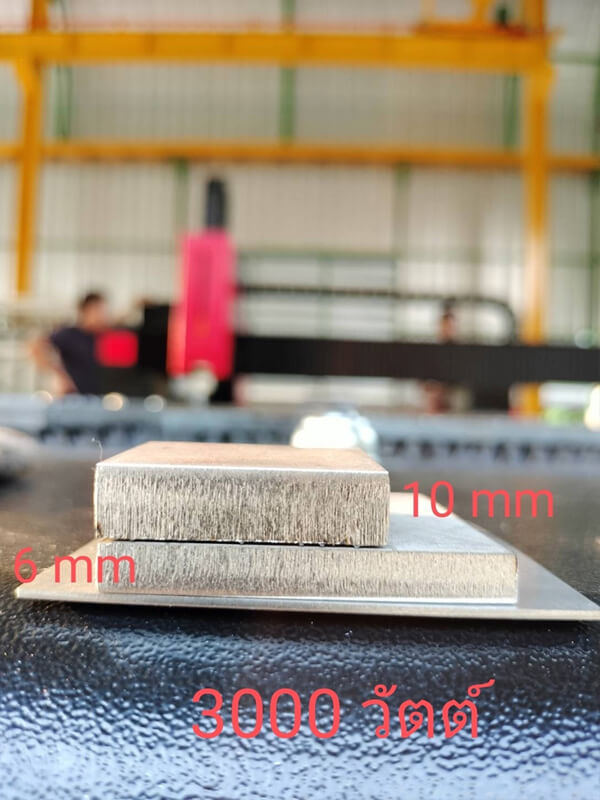

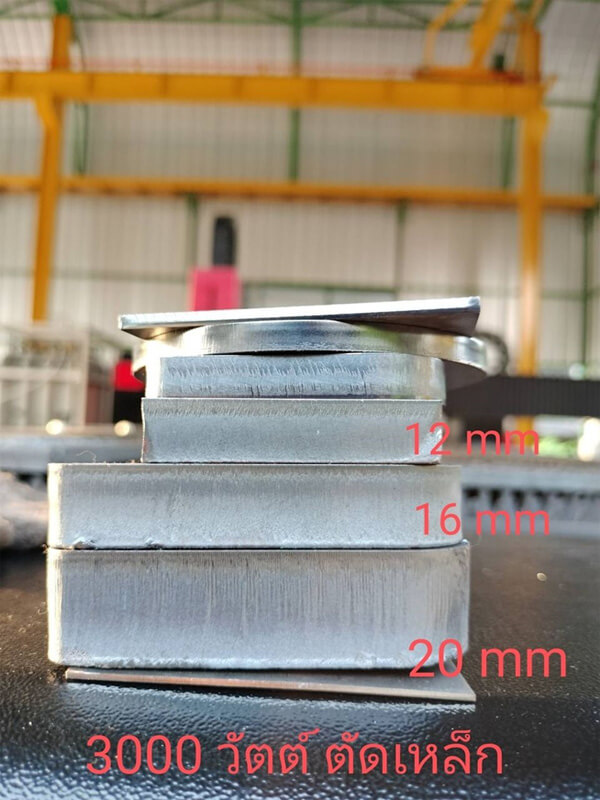

Let's have a check of our samples, which all from the real customer site. Below pic is a Remcor 3000w laser cutting machine cutting stainless steel 1.5-3-6-9-12-16-20 mm

The cutting edges all were clear with almost no burrs, smooth and beautiful edges even for the corners. As we know, the most important for stainless steel pipe laser cutting machine, is the cutting edge with different materials and different powers. If the cutting edges of the metal pipe cutting laser machine were not acceptable, normally need to test and debugged again and again and again. It's a big challenge for most manufacturers and customers.

Real Speed for Remcor 3000w Laser Cutting Machine Cut Holes for 1.5mm Stainless Steel

Remcor 12kw Laser Cutting Machine Cutting Steel SS400 8 mm

As we know, all the customers cared about the final cutting performance, no matter what the system has been used, what laser head brand and also the laser source. The cutting performance or cutting edges and cutting speed were the most important. Compared with other laser cutters like machine used to cut sheet metal, our advantages were listed as below

Not only focused on equipment manufacturing for 18 years, we also focused on the final cutting performance, Not all customers can handle the low power fully, sometimes the edge is not good, sometimes the speed is low… Remcor laser makes this point in a simple way.

The best quality laser cutters come from top quality components, The bed structure, the source, the head, the system, the motor, the rack and gear and guide, the smoke exhaust system, all parts were applied from the super brands to ensure the precision and durability

More than your needs, Take example, for our 3kw laser cutting machines, the structure we applied is actually available for 6kw, which ensure last a longer life-time. And the motor engine, we apply the higher power compared with the other brand laser cutters which can lead a faster speed in cutting. Some more tips are applied because we are happy to see our customer smile.

Anti-collision, automatically jump the tackle. Which can protect the laser head in some occasions

Cutting stainless steel without burrs, more smooth and clean edges from our cutters.

Faster cutting speed, the technology adjustment ensures a faster speed in cutting.