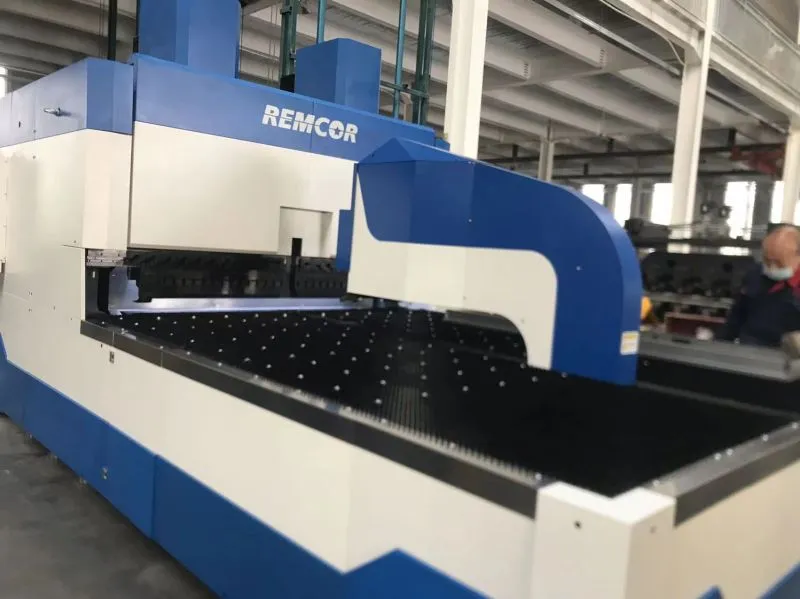

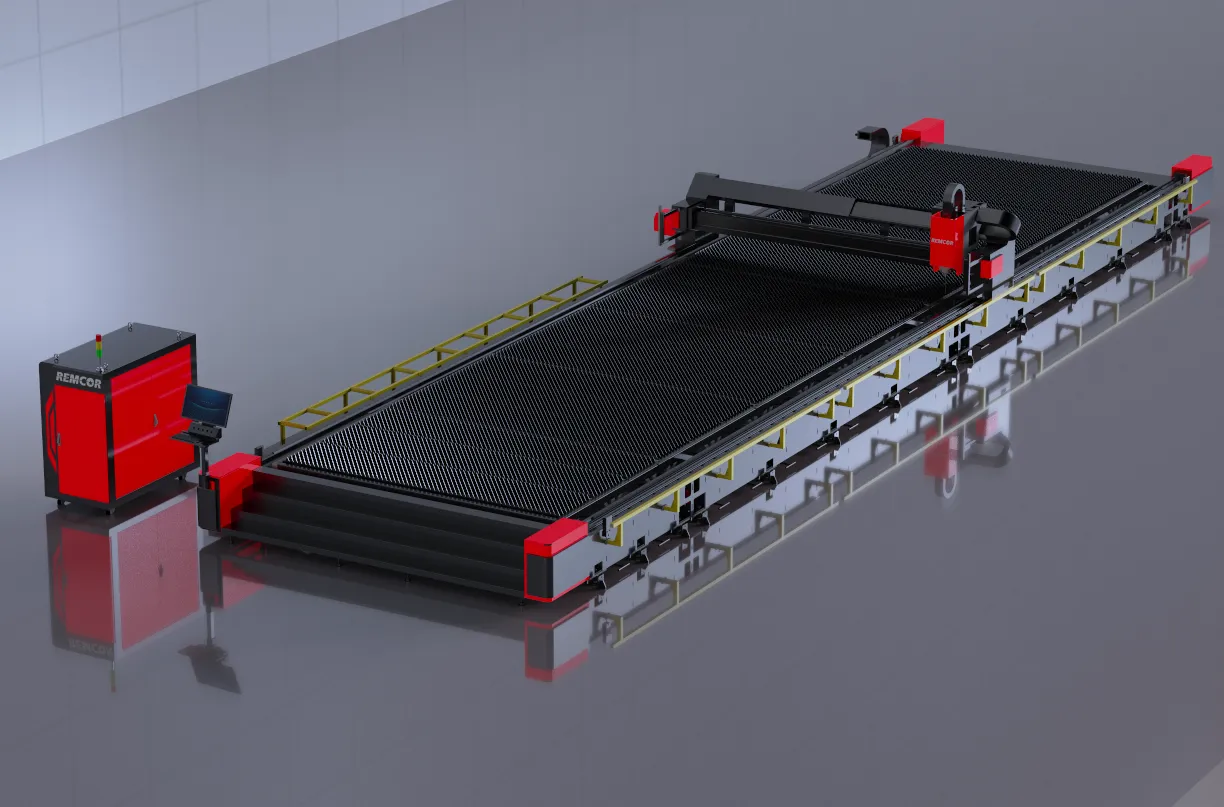

SA-3 series is the entry type of swiss type lathe. Support max processing diameter with 26mm.One machine can quickly perform turning, milling, drilling,tapping and side milling operations.

1. The machine structure and the main spindle module applies with the Meehanite cast iron with high rigidity rib design. The entire structure is cast in one go and treated to eliminate the stress. So that ensure the precision for a long time use

2. High-precision,High efficiency

The processing tolerance is ±0.003mm,The higher efficiency which is driven by the new controller and motor, shorten the processing time

3.Excellent universal processing capacity

The excellent cutting tools ensure the processing performance and increase the customer satisfaction

4. Wide range of material processing

Good at processing a variety of materials, including stainless steel, aluminum alloy, copper, titanium alloy, suitable for application scenarios in different fields.

Item | SA263 | SA203 | ||

Maximum machining diameter | φ26mm | φ20mm | ||

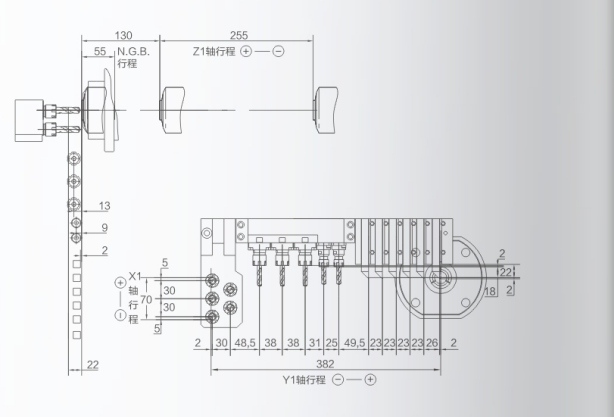

Max headstock stroke | Standard Guide bushing | 255mm | 255mm | |

Non-guide bushing | 2.5D | 2.5D | ||

turning tool | Quantity of tools | 6pcs | 6pcs | |

Tool specifications | □12mm | □12mm | ||

Face toolholder | Quantity of tools | front-end working | 5 pcs | |

Rear-end working | 2 pcs(Max. 5 pcs) | |||

Max.drilling | Fixed tools | φ10mm | ||

Max.tapping | Fixing tools | M8*P1.25 | ||

Cross tool unit | Quantity of tools | 5 pcs | ||

Tool specifications | ER16 | |||

Maximum drilling | φ8mm(ER16) | |||

Maximum tapping | M6*P1.0(ER16 | |||

Maximum milling | φ10mm | |||

Maximum milling slotting | Width 1.5, depth 4mm | |||

Spindle Speed | ER16 | 6,000min-1 | ||

Drive power | 1Kw | |||

Fast moving speed | Z1 | 32m/min | ||

X1 | 32m/min | |||

Y1 | 32m/min | |||

Main spindle Max. speed | 10,000min-1 (7,000min-1 G.B.) | |||

Main spindle indexing angle | C-axis control (0.001º) | |||

Main spindle power | 2.2/3.7kw | |||

Main spindle Through hole diameter | φ27mm | |||

Coolant capacity | 170L | |||

Cooling motor power | 0.4kw | |||

Overall dimensions (length*width*height) | 1900*1300*1780mm | |||

Machine weight | 2000kg | |||

Do not hesitate to give us a call or drop off a message if you have any question.

English

English русский

русский