Fiber laser technology has been widely used in construction projects due to their own strength, as well as low-carbon environmental protection, short construction periods and other advantages. Steel structure buildings play an important role in promoting the transformation and upgrading of the construction industry and also the newly laser technology plays an important role in it.

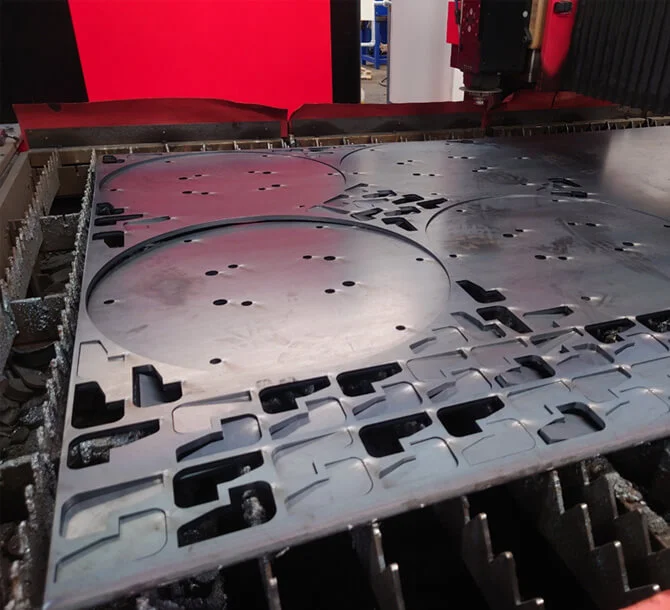

Great cutting performance. No need secondary grinding or processing.

Fast cutting speed and higher productivity especially for extra thick plates, the speed can be 5 times faster compared with traditional flame or plasma cutting.

High precision and high degree of automation. Reduce the cost.

Traditional flame cutting, plasma cutting, etc., due to the large mechanical pressure and heat conduction during the cutting process, the cutting efficiency is low, the precision is not high, and the workpiece is easily deformed. Especially when cutting V-shaped grooves, U-shaped grooves, X-shaped grooves and other grooves. This requires secondary processing, which is time-consuming and labor-intensive, and affects the quality consistency of steel structure products.

Our laser cutting system for hole plate cutting and bevel cutting with rich configuration and superior performance, It's perfect for the groove cutting. The entire processing process is fast and efficient without excessive manual intervention.

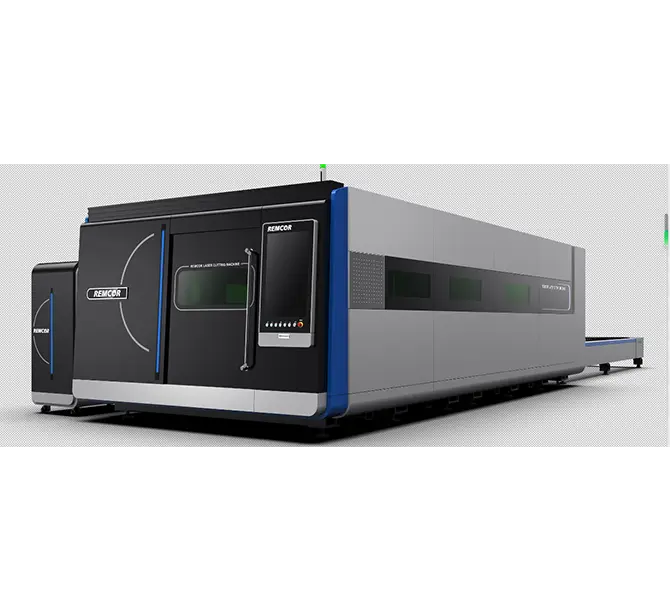

Remcor large format laser cutting machine is suitable for 6m-12m steel plate processing, and the structural steel laser cutting process does not require molds and other consumables. The equipment runs stably, has very low energy consumption, can run stably for a long time, and has a longer service life, which effectively reduces the production cost of the enterprise and improves the economic benefit of the enterprise. On the other hand, a large-format metal pipe cutting laser machine can realize bevel cutting. The flexibility of laser cutting processing is very high, which can fully meet the rapidly changing market demand, shorten the research and development and production cycle of steel structure products, and provide a strong guarantee for the rapid launch of new steel structure products and the rapid production of new projects.