The SPARK H fiber laser cutting machine represents the highest standard in Remcor’s product portfolio. It is designed for customers who require high power, extreme stability, and industrial-grade performance, while seeking a cost-effective alternative to traditional world-class brands such as Trumpf, Prima Power, and Bystronic.

If you previously used European laser cutting machines and are now considering a new fiber laser cutting machine with lower investment cost but without compromising quality, SPARK H is the ideal solution.

For first-time high-power users, 12000W fiber laser cutting machine is the recommended configuration.

In the Chinese market, 12000W has become a very mature and stable power level, widely adopted for industrial production.

High cutting speed and productivity

Stable long-term operation

Proven performance with multiple installations already running successfully

Fully verified by customer feedback and real production data

This makes SPARK H an excellent choice for customers upgrading to high-power fiber laser cutting machines.

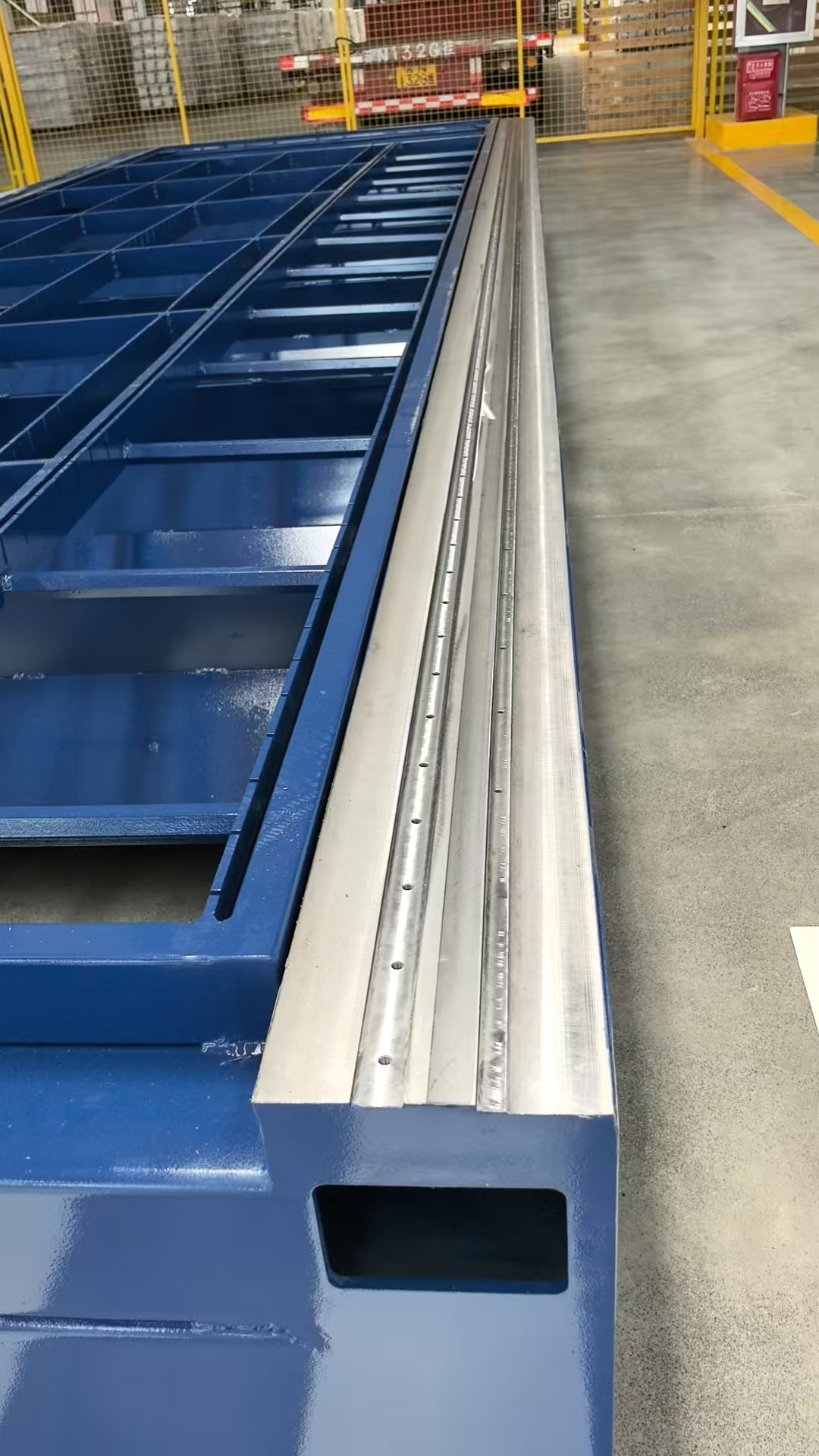

The SPARK H fiber laser cutting machine adopts a fully annealed welded plate structure, engineered for long-term industrial use.

Plate welding structure: 16mm thick steel

Multi-stage stress-relief annealing process

Heat treatment over 600°C to completely eliminate internal stress

Designed service life: 10 years

Key Advantages of a Strong Machine Body:

Higher loading capacity

For a 3015 single-table open-type fiber laser cutting machine, the loading capacity reaches 2 tons, enabling heavier sheet processing.

Superior stability at high speed

Even during high-speed acceleration and cutting, the machine operates without vibration or deformation, ensuring cutting precision.

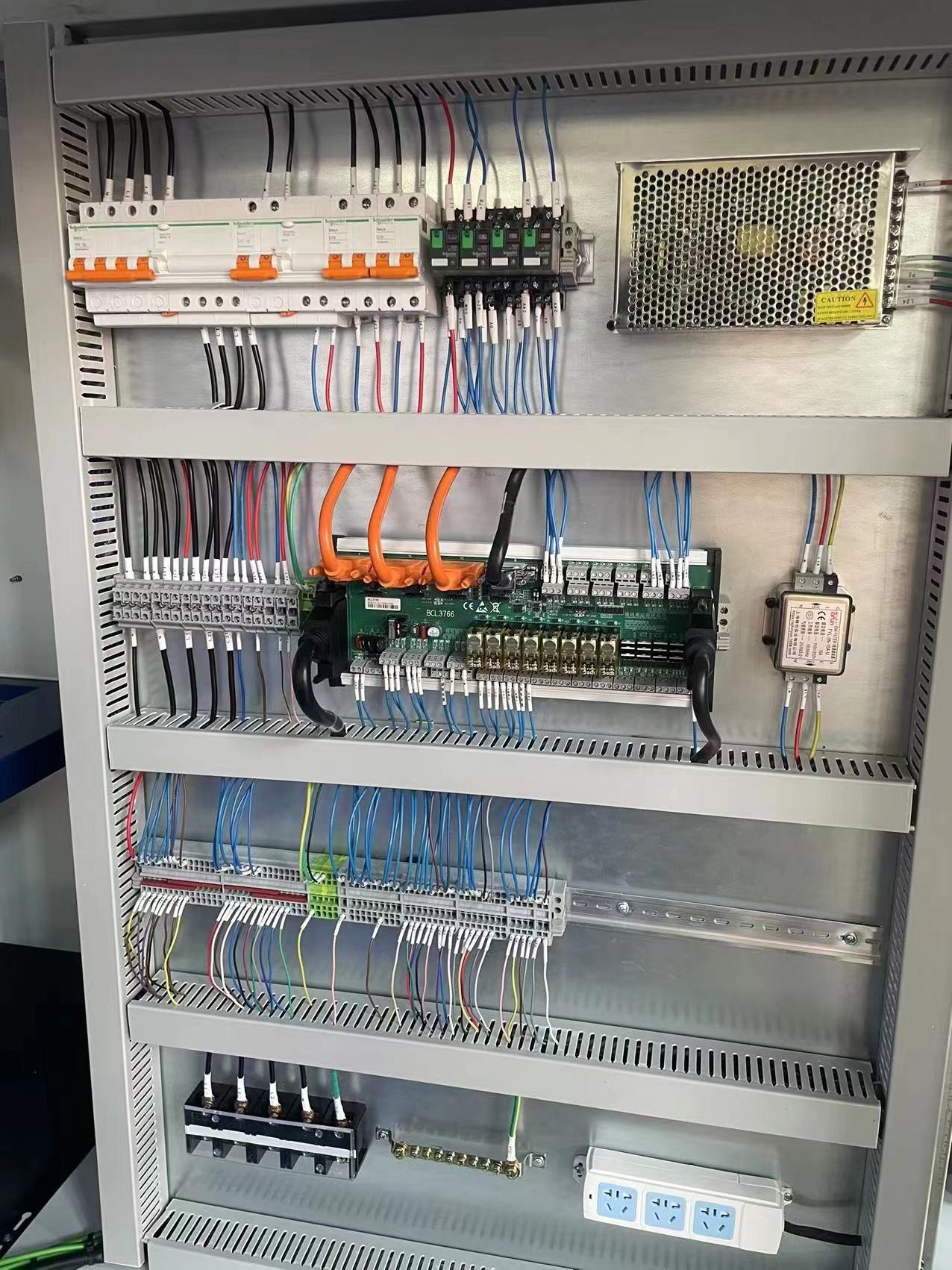

A high-standard fiber laser cutting machine must be equipped with high-quality components:

Servo motors & drivers: Yaskawa

Electrical components: Schneider

Globally recognized brands ensure:

Smooth motion control

Long service life

Easy replacement and local availability

This configuration guarantees reliability for long-term industrial operation.

The SPARK H fiber laser cutting machine features:

Oxygen (O₂) and Nitrogen (N₂) proportional valves

Three independent gas circulation systems

This design effectively prevents gas interference, improves cutting quality, and ensures stable gas pressure during high-power laser cutting.

The machine is equipped with an independent electrical cabinet, capable of housing:

3000W–6000W laser sources

Integrated industrial air conditioning system

This provides a stable cooling environment, especially important for hot and humid regions such as:

Thailand

Indonesia

Vietnam

It significantly improves electrical system reliability and component lifespan.

SPARK H uses a One-Piece Die-Cast Aluminum Alloy Gantry, a critical feature for high-end fiber laser cutting machines.

Lightweight with excellent rigidity

Ideal for high-speed cutting without loss of accuracy

Rhombus structural design enhances torsional strength and stability

Perfect balance between speed, strength, and precision

The SPARK H fiber laser cutting machine is equipped with the BOCHU CNC control system, which is:

Widely accepted by the global market

Easy to learn and operate

Highly stable and reliable for industrial use

This ensures fast operator training and consistent cutting performance.

Cutting area divided into left and right zones

Equipped with 300 × 300 mm full-hollow ventilation ducts

Improves smoke extraction efficiency

Enhances workshop environment and machine longevity

The SPARK H fiber laser cutting machine is equipped with an automatic lubrication system as a standard configuration.

All critical moving components of the fiber laser cutting machine require consistent and precise lubrication to ensure long-term stability and accuracy.

Key Benefits of the Auto Lubrication Function:

Automatically supplies lubricating oil to linear guides, ball screws, and transmission components

Ensures uniform lubrication at fixed intervals

Reduces mechanical wear and friction

Extends the service life of key components

Maintains stable precision during long-term, high-speed operation

Minimizes manual maintenance and human error

Although components are widely available, machine quality depends on assembly expertise.

SPARK H machines are built by experienced technicians with strict attention to:

Clean and organized cable routing

Precise mechanical alignment

High-quality surface finishing

Our pursuit is not only performance, but also industrial aesthetics and long-term reliability.

Every fiber laser cutting machine undergoes:

Full pre-testing

Sample cutting tests

24-hour idle running test

All test videos are sent to customers for confirmation before delivery, ensuring transparency and confidence.

Thanks to China’s advanced supply chain, high-quality components are now readily available.

However, Remcor insists on:

Higher configuration standards

Better structural design

More attractive pricing

Our goal is to make high-standard fiber laser cutting machines accessible to more customers worldwide.

The brand-new welded bed structure, undergoes multiple high-standard stress-relief processes to ensure lasting durability and guarantees high-speed, high-precision cutting

The machine body, the most important core parts for the machine, which designed for the 5 years lifetime use at least

![]()

![]()

The electrical components are separated from the bed body and come standard with a industrial constant temperature air conditioning,ensuring reliable and safe operation for both the electrical components and the laser.

The laser source (3000W-6000W) can also put inside the electric cabinet, which is necessary to have a better cooling by outside air conditioning, which is to save the space for the factory arrange

Do not hesitate to give us a call or drop off a message if you have any question.