Remcor, a laser machine company, provides fiber laser welding machine for sale with the character of high efficiency, low requirement for environment and operator. Even the new stuff can make good welding performance. low maintenance cost. Compared with traditional ARC welding, the fiber laser welding machine for sale is 2 times faster and more beautiful in welding speed and performance, and it is friendly to the environment. With so many advantages, which is widely applied in sheet metal fabrications.

The handheld laser welding machine for sale adopts fiber to transmit high energy and density laser, it's flexible and convenient to operate by welding the stainless steel, aluminum alloy and other materials by using the hand-held laser welding machine.

Hand-held welding machine is integrated with fiber lasers, hand-held welding head, laser control system, safety light extraction system and water cooling system. The overall design is small, beautiful, and portable, which make it easy for customers to choose their working environment without space limitation.

This fiber laser welding machine for sale can be widely used in billboards, metal door frames, water bottles, sanitary ware and mold repair industries.

Hand-held fiber laser welding machine, using infrared precise positioning, is flexible and convenient to make firm metal welding. The welding process leaves either no residues or consumables. The welding seams is not easy to deform, which is widely applied to welding large and medium-size workpieces, like cabinets, door and window frames, stairs, elevators, stainless steel furniture, chassis, etc...With various power, the fiber laser welding machine for sale can realize long-distance spot welding, full welding, continuous welding, sealed welding, etc. which will be a great helper for your metal design.

Item | Traditional welding | Handy laser welding |

Deformation/Undercut | Big | Small |

Strangeness | Normal, Cold Joint | Good |

Thin/Medium sheet welding | Not Suitable | Suitable |

Outlook, post-processing | Rough, need polish | Beautiful, without polish |

Welding speed | Normal | 2times than arc welding |

Operate difficulty | Complicated, need training | Easy(Except Complicated) |

Spare Parts | More gas consumption/spare parts | Less gas consumption/spare parts |

Environment | Smoky, harmful to health | Environmentally |

Welding quality | Normal | Good |

New green laser welding. Compared with traditional argon or tig mig welding, the laser welding is quite more friendly to the operator and also to the environment.

3 or more times faster speed in welding, compared with traditional welding.

Low cost in labors, no need professional welding operators. Even the beginners can have good welding finish, no need secondary polish after welding.

All the main parts of the fiber laser welding machine for sale were built in from the original famous brand, which ensures 8-10 years lifetime for the equipment.

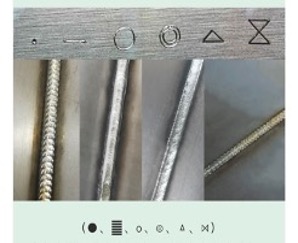

Meet different light spot requirement such as Internal corner, outer corner, downward welding, cladding welding etc.

Swing range of focus point position (power density) can be adjusted, adjusting range:0.2-5mm.

Item | Model | Features |

1 | ● | Small light spot with high power, which is suitable for the welding through and cutting |

2 | ○ | Width can be adjusted with a certain welding capability to thick material, which is suitable corner welding, tailored welding, wire feeder etc. |

3 | ◎ | Diameter can be adjusted for a purpose to have a larger light spot area to get a average light distribution by reducing the light spot center distance |

4 | - | Width can be adjusted with a certain welding capability to thick material, which is suitable corner welding, tailored welding, wire feeder etc. |

5 | ∆ | Width can be adjusted to reduce the light spot center distance along with that 3 lines power to heat averagely to the middle and both sides, the welding light spot can be scaly if we lower the frequency by using the wire feeder |

6 |  | Increase the light spot based on the triangle model to heat the sheet repeatedly for a larger width welding |

Model | AWN-1000 | AWN-1500 | AWN-2000 | AWN-3000 |

Laser type | Continuous fiber laser | |||

Rated output power | 1000W | 1500W | 2000W | 3000W |

Power adjustment range | 10%~100% | |||

Laser center wavelength | 1080±3nm | |||

output method | Continuous/modulation | |||

Maximum modulation frequency | 50kHz | |||

Power instability | <3% | |||

Fiber output interface | QBH | |||

Indicating system | Red light | |||

Length of welding torch cable | 8m | |||

Torch type | Wobble welding head | |||

Collimated focal length | 60mm | |||

Focus focal length | 150mm | |||

Torch weight | About 0.8 kg | |||

Protective gas | Coaxial protection | |||

Adjustable weld width | 0~5 mm | |||

product structure | All-in-one | |||

Product size L*D*H | 1200*600*1300mm | |||

product weight | 240kg | 270kg | 330kg | |

Working temperature | 0~40℃ | |||

Working environment humidity | <70% | |||

Operating voltage | Single-phase 220VAC (must be grounded) / three-phase 380VAC (must be grounded) | |||

Total power | <5kw | <7kw | <9.5kw | <11.5kw |

Recommended welding thickness for different materials | ||||

Material | AWN-1000 | AWN-1500 | AWN-2000 | AWN-3000 |

Stainless steel | 1.5mm | 2mm | 3mm | 6mm |

Carbon steel | 1.5mm | 2mm | 3mm | 5mm |

Galvanized sheet | 0.5mm | 1.5mm | 2mm | 3mm |

Aluminum alloy | 1mm | 1.5mm | 2.5mm | 3mm |

Remcor, a leading fiber laser welding machine supplier, offers state-of-the-art professional fiber laser welding machines known for their precision, efficiency, and versatility. As one of the premier laser welding machine manufacturers and suppliers, Remcor's machines find applications across various industries, revolutionizing processes with their advanced technology. Here are several key applications:

Automotive Industry: Remcor's fiber laser welding machines for sale are crucial in the automotive sector for welding components like car bodies, EV batteries, and exhaust systems. The precision of these machines ensures strong, reliable joints, enhancing vehicle safety and performance, which is why they are preferred by top-tier laser welding machine manufacturers.

Aerospace Industry: The aerospace industry demands lightweight, durable materials. Remcor's laser welding machines for sale are perfect for welding thin-walled components and high-strength materials such as titanium and aluminum. Their ability to produce clean, precise welds with minimal heat input maintains structural integrity and reduces material deformation, setting a high standard among fiber laser welding machine suppliers.

Medical Device Manufacturing: In the medical field, precision and cleanliness are paramount. Remcor's fiber laser welding machines for sale are used to manufacture surgical instruments, implants, and diagnostic equipment. Their high precision facilitates the creation of complex, small-scale components with minimal thermal distortion, a hallmark of top-notch laser welding machine company.

Electronics and Microelectronics: The electronics industry, which requires the miniaturization of components, benefits greatly from Remcor's fiber laser welding machines for sale. They are essential for welding delicate electronic components, circuit boards, and connectors. Their pinpoint accuracy without damaging adjacent areas ensures the functionality of electronic devices, proving Remcor's excellence among laser welding machine manufacturers.

Jewelry and Watchmaking: These industries require detailed, intricate work, and Remcor's laser welding machines for sale deliver. They are used to repair and create fine pieces, ensuring high-quality joints that often remain invisible. This precision helps maintain the aesthetic and functional quality of luxury jewelry and timepieces, reinforcing Remcor's reputation among fiber laser welding machine suppliers.

Energy Sector: In renewable energy, Remcor's fiber laser welding machines for sale are indispensable for producing solar panels and battery packs. They ensure strong, efficient welds, crucial for the longevity and performance of energy storage and conversion systems, highlighting Remcor's innovative solutions in the market of laser welding machine companies.

Tool and Mold Making: Remcor's fiber laser welding machines for sale are used to repair molds and dies in tool-making. They allow for precise material addition and modifications, extending the life of expensive molds and reducing downtime, showcasing why Remcor is a preferred choice among fiber laser welding machine manufacturers and suppliers.

These applications demonstrate the versatility and essential role of Remcor’s professional fiber laser welding machine factory in China, showcasing its advanced manufacturing capabilities across a range of high-tech and precision-dependent industries.

Selecting a fiber laser welding machine in China involves careful consideration of several key factors to ensure you get the best equipment for your needs. Here's a guide to help you make an informed decision, incorporating insights from top fiber laser welding machine suppliers and manufacturers.

Determine Your Requirements: Before approaching any laser welding machine company, clearly define your welding needs. Consider the types of materials you will weld, the thickness of these materials, and the required welding speed and precision. This initial step helps narrow down the options among various fiber laser welding machine manufacturers.

Research Reputable Manufacturers and Suppliers: Look for well-established fiber laser welding machine manufacturers and suppliers in China. Companies with a solid reputation often offer better quality fiber laser welding machines and after-sales support. Check online reviews, industry forums, and customer testimonials to gauge the reliability of these companies.

Evaluate Machine Specifications: Compare the technical specifications of fiber laser welding machines for sale from different laser welding machine suppliers. Key specifications to consider include laser power, wavelength, beam quality, and cooling system. Ensure the machine’s capabilities align with your specific welding requirements.

Consider Automation and Software: Advanced fiber laser welding machines for sale come with automation features and sophisticated software for improved efficiency and precision. Evaluate the ease of use, programming capabilities, and compatibility with your existing systems.

Assess Build Quality and Durability: Inspect the build quality of the machines. Robust construction and high-quality components ensure longevity and consistent performance. Leading fiber laser welding machine manufacturers typically use superior materials and advanced manufacturing techniques.

Check for Certification and Compliance: Ensure the machine complies with international safety and quality standards. Certifications from recognized bodies indicate the machine meets stringent quality requirements, reflecting the credibility of the laser welding machine company.

After-Sales Support and Training: Reliable after-sales support is crucial for maintaining and troubleshooting your machine. Opt for fiber laser welding machine supplier who offers comprehensive training, technical support, and readily available spare parts.

Price and Warranty: Finally, compare prices and warranty terms from different suppliers. While cost is important, prioritize quality and support. A slightly higher investment in a reliable machine from a reputable manufacturer can result in better long-term value.

By following these steps, you can select a fiber laser welding machine in China that meets your needs, backed by the reliability and support of top laser welding machine companies, manufacturers, and suppliers.

Do not hesitate to give us a call or drop off a message if you have any question.