Nov 12 , 2025

Handheld laser welders are designed for simplicity, precision, and speed — making them one of the easiest modern welding technologies to learn. Compared with traditional MIG, TIG, or arc welding, fiber laser welding machines require less manual skill and deliver higher-quality results with minimal distortion or cleanup. Once you understand the basic setup and parameters, you can begin producing professional welds in just a few hours of practice.

When operating a handheld laser welding machine for sale, the process works by focusing a concentrated laser beam onto the material’s surface, rapidly melting and joining metal edges together. This advanced technology produces deep, narrow, and strong welds with minimal heat impact on surrounding areas.

Advantages include:

High welding speed and efficiency

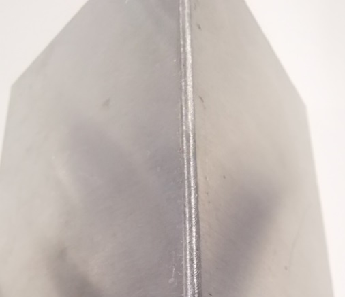

Smooth, clean weld seams with no need for polishing

Minimal thermal deformation

Low operating cost and long machine lifespan

Suitable for stainless steel, carbon steel, aluminum, copper, and more

This makes handheld laser welders ideal for industries like metal fabrication, kitchenware, automotive repair, and stainless-steel furniture manufacturing.

Before operating, several key components must be properly connected(Which we take one of the most common system in the market for example to introduce one by one)

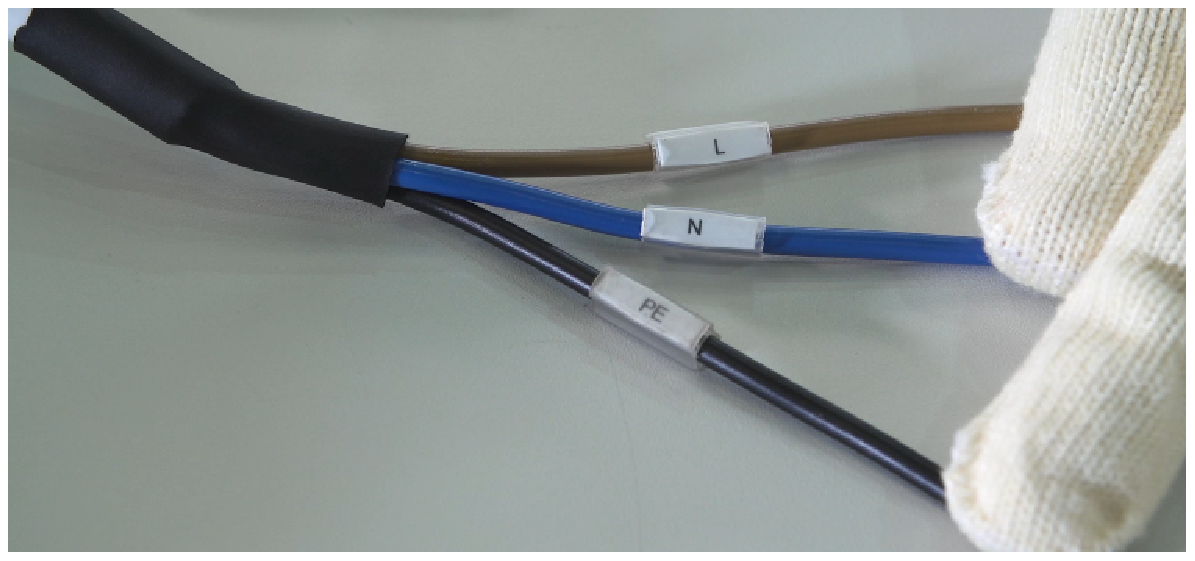

Power supply– provides stable energy to the machine

Normally need 2 lines, L & N

Sometimes need 5 lines, U, V, W, N & ground wire

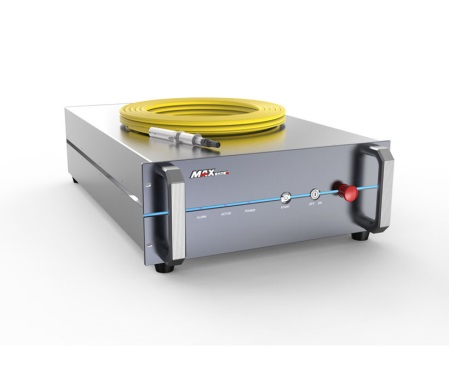

Laser source(CW) – the core of the system that generates the welding beam.

The power is from 1500W to 3000W,some even up to 6000W

the higher power, which have a higher penerations for the materials

Which also have a welding parameter data from our company, which is free to give our customers for the guidance

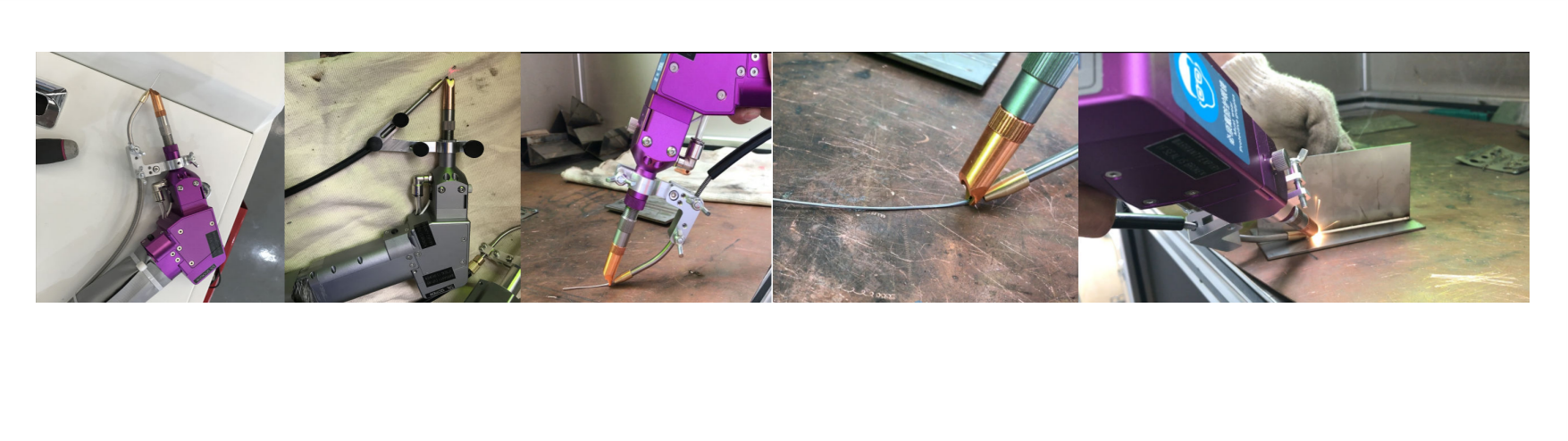

Laser Welding gun – the core parts of the welding machine

Water chiller – cools the laser source and gun to prevent overheating

The industrial water chiller keeps the laser source and gun at optimal temperature during operation. It prevents overheating and ensures stable laser output, which is crucial for long-term reliability and consistent weld quality.

Suggestion: Purified water is recommended, and fill the water to the level which need

Gas supply – A shielding gas—usually argon, nitrogen, or helium—is used during laser welding to prevent oxidation, improve weld appearance, and enhance strength.

Consistent gas flow is critical for achieving high-quality welds, particularly in stainless steel and aluminum applications.

Nitrogen is mainly used for the stainless steel welding

Argon is for all the material welding

Air flow suggestion: more than 15L/min

the purity is up to 99.998%

Wire feeder (optional) – automatically supplies filler wire for joining gaps or thicker materials.

It have 2 types including the single wire feeder, double wire feeder

Single wire feeder: it have one roller to feed 1 pcs of the wires to be melted into the base material

Double wire feeder: It have 2 rolleer to feed 2 pcs of the wires simultaneously which is for the big gaps

Once connected, the machine can be powered on, calibrated, and ready for operation.

The Controlling System and Welding Gun

Modern handheld laser welding machines come with a smart, user-friendly control system. Through a touchscreen interface, operators can easily adjust power, mode, and welding speed.

The handheld welding gun is lightweight, ergonomic, and designed for comfortable use over long periods. It offers flexible movement, making it easy to weld in tight or irregular positions — a major advantage over traditional fixed welding setups.

The Welding Parameters

To achieve the best results, key welding parameters must be adjusted according to the material type and thickness:

Laser power : Power: 0-100%, the suitable power depends on the thickness (Power ≈ thickness /1.5)

Frequency: 50-30000Hz, Recommended 3000-5000Hz, no need to adjust

Duty cycle: 0-100% depends on welding depth

Duty cycle can be reduced appropriately once the thin material not yet welded through No need to adjust

Welding speed: the welding speed depends on the power, and material thickness, the material type, and gas pressure etc. which is a very important data once to achieve the perfect welding performance

Normally for our machine, it is preset inside into the controlling system, it have the welding database, just choose the suitable data according to the material type and thickness etc.

Pulse frequency and duration

Gas flow rate

Proper parameter setup ensures strong, uniform, and visually clean welds.

Gas blow advance and delay are recommended to be set at about 200ms to protect the lens free of pollution. it can be increased appropriately once with heavy smoke

Proportional valve: gas control can be by percentage control if with proportional valve(To be developed)

Wire Feeder

A wire feeder can be attached to the laser welding machine for applications that require filler material. It ensures smooth, continuous wire delivery and helps bridge gaps between parts. This improves weld strength and appearance, especially on uneven joints or thicker materials.

Consumable Parts Change

Some consumable parts require periodic replacement to maintain performance, such as:

Protective lenses

Steps by steps by the below

Loosen protective lens mounting nut.

Keep welding head level. And seal the mounting port to prevent dust

Take out the protective lens from the groove.

Replace new lens, install the washer on and press tight until to hear "crack" sound

Install the lens holder and fasten nuts Replacement complet ed

Check the protective lenses regularly and wipe by alcohol or isopropyl alcohol. or replace them When to change protection lens

Once energy is obviously weakened during welding, but most of them have burning point at the lens, so it is time to change

Nozzles & Copper tips

Fiber connectors

Regular maintenance and replacement extend machine life and guarantee stable welding quality.

Laser welding is safe when handled properly. Operators should follow these safety requirements:

Wear laser-protective glasses

Use protective gloves and clothing

Avoid direct eye or skin exposure to the laser beam

Operate in a ventilated area

Follow manufacturer safety guidelines and certifications

Proper safety measures not only protect the user but also ensure reliable and compliant operation.

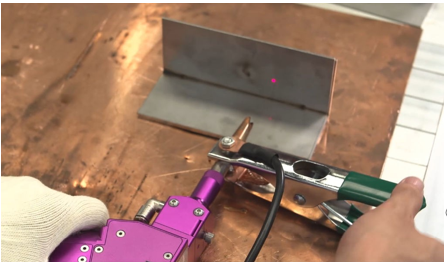

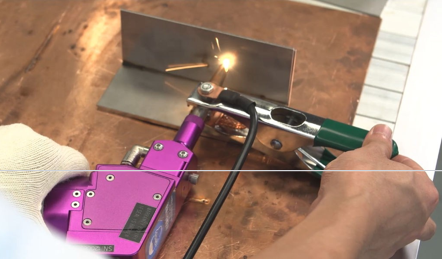

1. Focus adjusting

Adjust the power to less than 30%, choose DOT model(It is also for the metal cutting), dot is also used to fix the overlap welding

Loosen screw nut of the rebar pipe

Clamp the GND clamp to the rebar pipe

Move the head towards to the sheet with continuous light and find out the brightest point(Highest energy). it is focus point, normal tolerance range ±3mm

(One material only need one time to find out the focus, focus of Stainless/Aluminum is different)

Handheld laser welders by Remcortechnology laser machine factory are powerful, easy-to-learn tools that combine efficiency, precision, and safety. With a basic understanding of the setup — including the laser source, gas supply, wire feeder, and cooling system — anyone can start welding high-quality metal joints quickly. Whether you’re a beginner or a professional fabricator, laser welding technology offers a modern, clean, and cost-effective solution for all your metal joining needs.