Yes sure, we works as one of the professional panel bender manufacturers welcoming the global partners for vising us and also welcome to make an appoint with our manager for checking the CNC panel bender in locally.

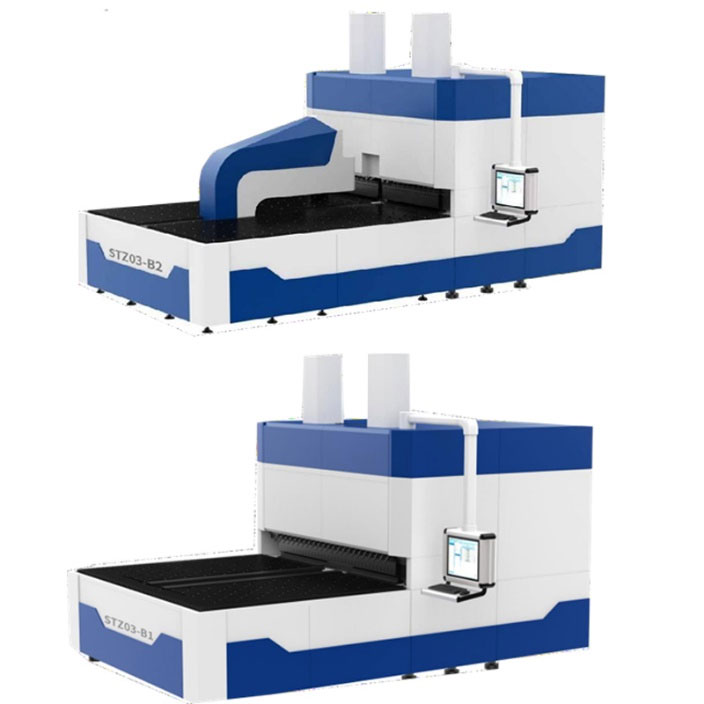

The intelligent flexible bending center is a high-tech product developed and produced for the sheet metal industry to improve production efficiency, reduce labor intensity, reduce labor costs, and enhance corporate image. The CNC panel bender has been widely used in various industries such as filing cabinets, electrical cabinets, door industry, tool cabinets, kitchen utensils, ventilation, air conditioning, elevator industry, purification, education and experimental equipment.

High productivity. The fastest continuous bending speed of the panel bender for sale can be 0.5S and can realize the automatic and continuous bending. The cycle time saving up to 60% compared to the die bending.

Flexible and high automatic processing. Flexible bending multiple sides, less re-tooling time. Labor cost saving at 4-5 times compared with traditional press brake.

Precise bending. The very first step manual positioning and imported servo motor control the bending process precisely.

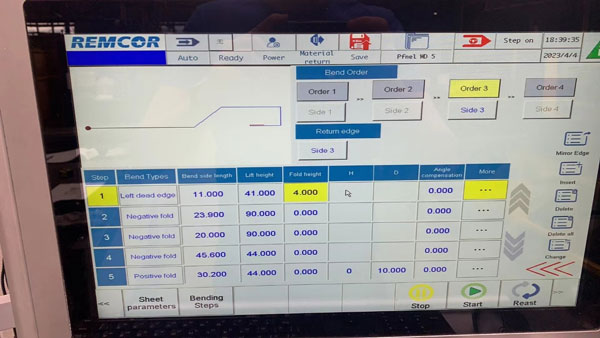

Simple operation. Clear and simple windows, the CNC panel bender for sale can handle the bending process in a easier way.

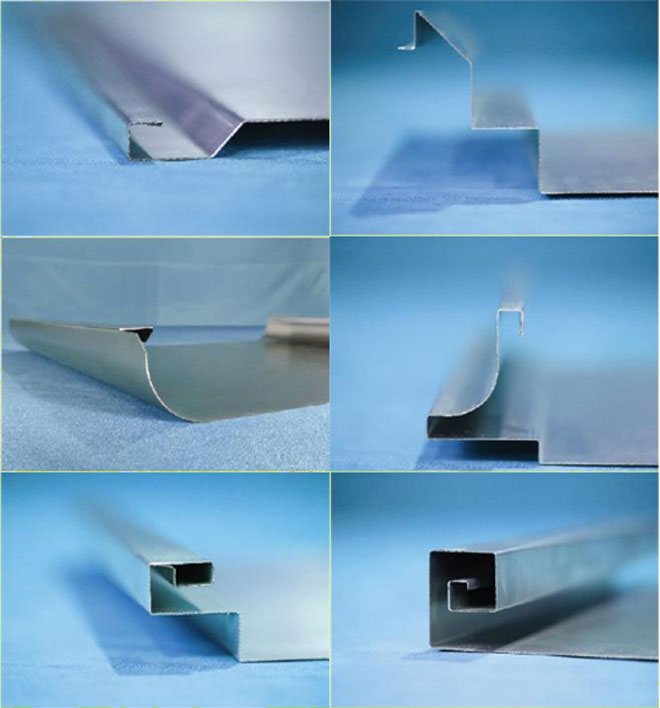

The intelligent bending center can realize complex shapes such as bending right angles, non-right angles, circular arcs, upper and lower pressing dead edges, etc., and is used in the metal forming field of different workpieces in different industries; the CNC panel bender for sale adopts all-electric servo motors instead of hydraulic drives, which is environmentally friendly, fast speed, high precision, maintenance-free and other advantages.

There are two types of casting parts and steel plate welding parts for the body of panel bender for sale, which can meet the needs of different processes, products and users.

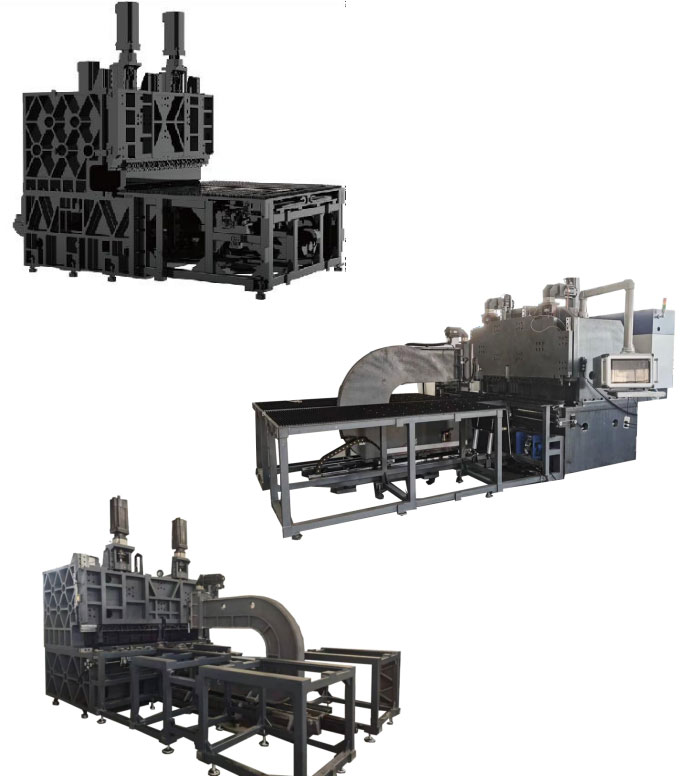

The cast fuselage frame of the panel bending machine undergoes precise finite element force analysis, adopts the most stable circular radial triangle interconnection design, and selects high-grade QT500-7 and HT250 or higher castings after strict material analysis.

The welding fuselage is made of Q235 high-quality steel plate, which is welded on a special platform after advanced welding technology, which ensures the welding accuracy of the fuselage; This greatly ensures the overall stability of the fuselage under high tonnage force.

Both fuselages are subjected to a high-temperature annealing process according to the temperature curve corresponding to the material and are subjected to large-scale.

The shot blasting machine is cleaned of sand, and the bed's surface is clean. Castings and welded parts are subjected to open-air aging treatment after rough machining. Thoroughly release the internal stress before doing fine processing to ensure that the CNC panel bender will not deform for a long time and ensure the stability of the complete accuracy.

The bending tool is made of 42CrMo forging material, which is made through strict roughing, finishing and other processes, as well as heat treatment, quenching and tempering, laser quenching and other processes, ensuring the service life of the tool and bending requirements. Different straight knives, scimitars, large scimitars, upper and lower pressure knife avoidance, hinge knife pneumatic, electric control and other knives can be designed and customized according to the user's workpiece, and auxiliary bending knives can also be installed for complex bending processes to maximize to meet various bending needs.

The imported all-electric servo closed-loop control system is adopted. The handheld laser welding system supports up to 25 axes of concurrent linkage. In the true sense, the multi-axis is concurrently linked, the bending action is smooth, and the mechanical operation is highly coordinated.The panel bender for sale can connect different brands of manipulators and truss loading and unloading equipment according to its own needs.

The programming software is easy to learn, intelligent operation, practical. The edited workpiece shape is displayed at any time, and the self-inspection system can predict whether the edited program is correct in advance, avoiding the waste of workpieces and effectively protecting the CNC automatic panel bender. In terms of function, it supports complex movements such as upper pressing dead edge, lower pressing dead edge, and arc that cannot be formed at one time by traditional bending machines.

The control system has a cloud operation and maintenance management interface, which can use the mobile phone applet to monitor the operation status of the panel bender for sale anytime and anywhere, understand the actual operation status of the equipment, and count the number of production workpieces in various periods.

Description | RMZ03-A2 | RMZ03-B1 | RMZ03-B2 | RMZ03-B2 | RMZ03-C2 | RMZ03-D2 | RMZ03-E2 |

Maximum bending speed | 0.2 S/knife | 0.2 S/knife | 0.2 S/knife | 0.2 S/knife | 0.3 S/knife | 0.5 S/knife | 0.6 S/knife |

Maximum bending length (CM) | 100*100 | 140*125 | 140*125 | 160*125 | 200*150 | 250*150 | 320*150 |

Maximum bending height (mm) | 170/210 | 170/300 | 170/300 | 170/300 | 170/300 | 170/300 | 170/210 |

Feeding method | Compression arm | suction cup | Compression arm | Compression arm | Compression arm | Compression arm | Compression arm |

Feeding table | Brush, universal ball | Brush, universal ball | Brush, universal ball | Brush, universal ball | Brush, universal ball | Brush, universal ball | Brush, universal ball |

Lubrication line | copper pipe | copper pipe | copper pipe | copper pipe | copper pipe | copper pipe | copper pipe |

Minimum bending thickness (mm | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 |

The minimum size of four-sided molding | 200*280mm | 200*280mm | 200*280mm | 200*280mm | 200*280mm | 200*280mm | 200*280mm |

The minimum size of unilateral forming | 150mm | 150mm | 150mm | 150 mm | 150mm | 150mm | 150mm |

hinge knife | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

Advanced instructions | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

Arc command | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

Suction cup set up and down | Optional | ||||||

Presser foot lift | Optional | Optional | Optional | Optional | Optional | Optional | Optional |

C-axis lift | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

Automatic lubrication function | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

Offload detection function | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

Eccentric load follow-up function | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

Plate thickness detection function | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

Automatic feeding interface | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

High speed control module | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

Flattening function | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

up and down dead side | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

Folding knife adjustment device | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

Manual wheel operating | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

Cloud management function | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

Rated voltage | 380V | 380V | 380V | 380V | 380V | 380V | 380V |

Maximum bending thickness (mm) | SS 1.0 CS 1.2 AL 1.5 | SS 1.2 CS 2.0 AL 2.5 | SS 1.2 CS 2.0 AL 2.5 | SS 1.2 CS 2.0 AL 2.5 | SS 1.2 CS 2.0 AL 2.5 | SS 1.2 CS 2.0 AL 2.5 | SS 1.2 CS 2.0 AL 2.5 |

Dimensions (CM) L*W*H | 310*150 | 350*200 | 450*200 | 450*250 | 510*270 | 570*310 | 700*380 |

*280 | *280 | *280 | *280 | *280 | *280 | *280 |

Quality and Reliability: REMCOR, one of the leading panel bender manufacturers, is known for producing high-quality machinery that is reliable and durable. Their CNC panel benders are often manufactured using advanced technology and precise engineering, ensuring consistent performance over time.

Customization Options: REMCOR, a professional laser cutter exporter, may offer customization options for their panel bending machines to suit specific needs and requirements of customers. This flexibility can be invaluable for industries with unique production demands.

Technical Support and Service: Among the panel bender manufacturers, REMCOR typically provides excellent technical support and service to its customers. This includes assistance with installation, training, maintenance, and troubleshooting, ensuring smooth operation of the CNC panel bender.

Innovation: REMCOR is likely to invest in research and development, leading to innovative features and improvements in their automatic panel benders. This can translate to enhanced productivity, efficiency, and versatility in panel bending operations.

Industry Reputation: REMCOR may have a strong reputation within the manufacturing industry for producing high-quality machinery. Positive reviews and recommendations from other customers can instill confidence in choosing REMCOR for a panel bender for sale.

Cost-effectiveness: While initial investment costs are important, REMCOR may offer panel bender for sale that provides excellent value for money over their lifecycle. Factors such as energy efficiency, reduced downtime, and low maintenance requirements can contribute to long-term cost savings.

Compliance and Safety: As a trusted laser machine company, REMCOR is likely to adhere to industry standards and regulations concerning safety and compliance. This ensures that their panel benders meet necessary safety requirements, providing peace of mind to operators and owners.

Panel benders, also known as CNC panel benders or press brakes, come in various types, each designed to suit specific manufacturing needs and requirements. Here are some common types of panel benders:

Manual Panel Benders: These are basic CNC panel benders for sale operated manually by the operator. They are suitable for small-scale operations or applications where precision and speed are not critical factors.

Hydraulic Press Brakes: Hydraulic press brakes use hydraulic cylinders to exert force on the bending tool, allowing for precise and powerful bending of metal sheets. They are suitable for a wide range of applications and offer high accuracy and repeatability.

Servo-Electric Press Brakes: These press brakes use servo motors instead of hydraulic systems to drive the bending mechanism. They offer high precision, energy efficiency, and low maintenance requirements. Servo-electric press brakes are often preferred for applications requiring high-speed bending and intricate shapes.

CNC (Computer Numerical Control) Press Brakes: CNC press brakes are equipped with computerized controls that allow for precise control over the bending process. Operators can program the machine to bend metal sheets into complex shapes with high accuracy and repeatability. CNC press brakes are highly versatile and suitable for a wide range of applications.

Tandem Press Brakes: Tandem press brakes consist of multiple press brake machines operated in tandem to increase bending capacity and efficiency. They are used for bending large and heavy metal sheets or for high-volume production.

Box and Pan Brakes: Box and pan brakes, also known as finger brakes, are specialized bending machines used for bending metal sheets into boxes, pans, and other complex shapes with straight sides. They feature adjustable fingers that allow for precise bending along multiple axes.

Panel Folding Machines: CNC panel benders are designed specifically for folding metal sheets along straight lines to create sharp bends. They are often used in industries such as HVAC, roofing, and automotive for manufacturing panels and enclosures.

Choosing the right CNC panel bender involves considering several factors to ensure it meets your specific manufacturing needs and requirements. Here's a step-by-step guide to help you make the right decision:

Assess Your Bending Requirements:

Determine the type and thickness of materials you will be bending (e.g., steel, aluminum, stainless steel).

Consider the size and complexity of the parts you need to produce, including the required bending angles and tolerances.

Evaluate Machine Capacity:

Look for a CNC panel bender for sale that can handle the size and thickness of your typical workpieces.

Consider factors such as bending length, tonnage (bending force), and maximum bending angle.

Consider Automation and Productivity Features:

Assess the level of automation offered by the CNC panel bender, including features like automatic tool changing, material handling systems, and robotic integration.

Evaluate productivity-enhancing features such as fast setup times, quick tool changeovers, and high-speed bending capabilities.

Review Precision and Accuracy:

Look for automatic panel benders with advanced control systems and precision mechanisms to ensure accurate bending results.

Consider features such as crowning systems for compensating for deflection and maintaining uniform bending across the length of the part.

Examine Software and Programming Capabilities:

Evaluate the user interface and programming software provided with the panel bending machine.

Look for intuitive programming interfaces, simulation tools for verifying bending sequences, and compatibility with common CAD/CAM software.

Assess Reliability and Maintenance Requirements:

Research the reputation of the manufacturer and the reliability of their CNC panel benders.

Consider factors such as machine uptime, maintenance requirements, and availability of spare parts and technical support.

Yes sure, we works as one of the professional panel bender manufacturers welcoming the global partners for vising us and also welcome to make an appoint with our manager for checking the CNC panel bender in locally.

1. The cast Iron body, we adopt the most stable circular radial triangle interconnection design, and selects high-grade QT500-7 and HT250 or higher castings after strict material analysis. Castings and welded parts are subjected to open-air aging treatment after rough machining to ensure the stability of the complete accuracy.

2. The co-developed system with global famous controlling system. which supports the complicated cloud operation and it’s user friendly especially for foreign operators, also we specially preserve maintenance management interface, which can use the mobile phone applet to monitor the operation status of the CNC panel bender anytime and anywhere.

3. Rich experience in machining designing and production for steel cabinet or steel furniture industry till now, we have successfully shipped to Europe, which wins high appreciations. And over 13 sets automatic panel bender lines in domestic for the leading furniture industry manufacture.

Yes sure, pls firstly share with us the below points so we can offer our quotation for reference.

1) Your material type and coil width.

2) Your material thicknesses

3) The drawings you would need to do

4) Your coil weights

Do not hesitate to give us a call or drop off a message if you have any question.