Jan 29 , 2023

Nowadays, Fiber laser tube cutting machines are very common in the market, we choose it by the high speed, high precision, and higher flexibility etc. But also we know that there are so many kinds of tubes in the market.

Material type: Carbon Steel, Stainless Steel, Aluminum etc.

Thickness: 1-10mm, or even higher

Length: normally 6 meters, but sometimes also have 7M 8M, 9M, And even 12m

Size: Some tubes are very small, the round diameters only around 10mm, but some tubes are very big, even up to 350mm, and maybe more than that.

Normally we calculate the diameters by their diagonal size.

Take an example, the square pipe size is 1*1mm, So it is diameters we need to calculate like 12+12=2, then Square 2= √2=1.414

So square tube diameter, the diameter is 1.414

And C type (Channel tube), and “L” are the same way to calculate the diameters.

Type of the tubes: Round, Square, L, C (Channel), Triangle, Flat etc.

Finished length: Sometimes customer's in-feed length is 8m, but the finished tube length is also 8m, so also need to consider this kind of option once we choose the metal pipe cutting laser machine.

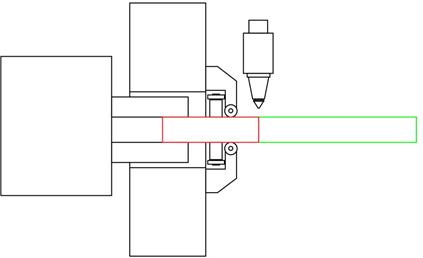

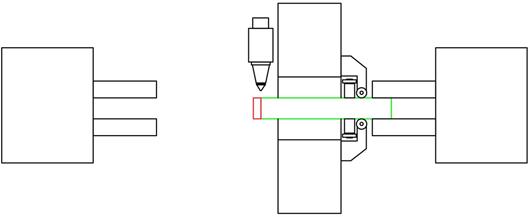

Tail Material length: This is an item that all the customers can not avoid, How to form the tail material, can be understood from the below picture

Weight of the length: It is the results by considering the length, thickness, material type, and size, then we can calculate the weight, As we know, the chucks are pneumatic clamps, the loading capability is limited, the chucks can not work once the weight is more than the chuck capability

The above items are the basic items we need to know, because of the type of sheet and tube laser cutting machine, we need to consider the above items.

Power: We need to consider the thickness of the material, type of the material, It is the same as plate cutting, higher power definitely a higher speed along with good surface

Length: We need to consider the tube length, if the tube length is only 6M, our stainless steel tube laser cutting machine at least 6 meters, and if our tube length is 8 M, 6 M for the tube cutting machines is not enough, we need to choose 8m tube cutting machines

Chuck diameters: As the above items mentioned, if our tubes are very small in size, take example the maximum diameter is only 200mm, our Chuck diameter is at least 200mm, but if the tube diameter is more than 300mm, definitely 200mm are not enough, we need to choose a 300 or 320 or 350mm Chuck diameters

Chuck capability: Normally the common type in the market is 6020, and the loading capability is around 160kgs, but if the tube weight is even more than 160kgs, the machines can not rotate, the machine can not work

Then the rest items are to the finished length and tailing material, we need to understand the difference between 2 chucks and 3 chucks

It is very easy to understand that 2 chucks only 2 chucks, the left chucks and the middle chucks

But 3 chucks have 3 chucks, the left chucks and middle chucks and right chucks

So it is really necessary that to add one more chucks? Is it useful or not? We need to compare it one by one

How to form

As the picture shows above: the areas for the left side of the head, the middle clamps and the right clamps claw are the blind area, where the cutting head cannot cut, the red part we call tailing material.

the length of tailing material from different laser tube cutting machine manufacturers is different just because the length by right clamps difference, normally 160-200mm

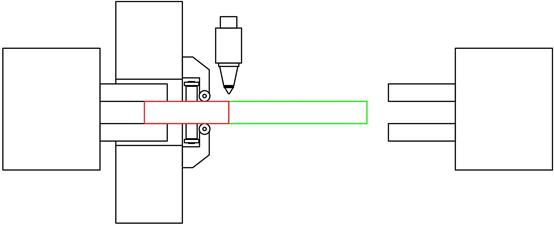

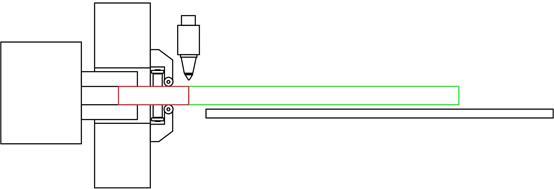

As the right picture shown, normally the left clamps will deliver the pipe into the center chuck once the right clamps open, currently the laser head just need to avoid collision to the right clamps to have the results to reduce waste material

Advantages: The solution is simple and easy to complete.

The tailing material length can be reduced to 80mm by simplified revise

Disadvantages: Only for small pipes, thin material pipes If heavy pipes, long pipes, the finish and precision can not meet together

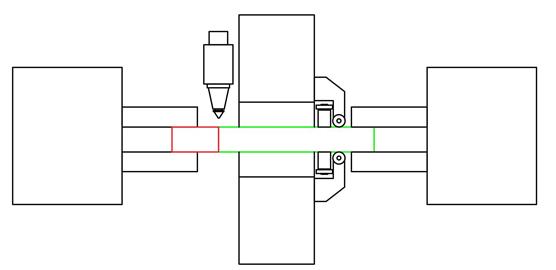

1. Nesting tailing material is more than 200mm

The machines will cut by the standard 2 chucks models, the third chuck will clamp as the set

The tailing material is 200mm

2. Nesting tailing material less than 200mm, more than 80mm, and final product length more than 900mm

The middle chuck moves to the right side, the laser head cut once the right one clamps The tailing material is 80mm

3. Nesting tailing material less than 80mm, the final product length more than 900mm

The middle chuck moves to right side, the left side clamps open, laser head cut the end places

The tailing material is 0-5mm

1. The tailing material length more than 200mm, 2 chuck model is available and make sure the precision

2. The tailing material length less than 200mm, more than 80mm, and the final product length is more than 900mm, and can make sure

the precision

3. The tailing length is less than 80mm and the final product length more than 900mm, and make sure the '0' tailing cutting

1. Need the final pipe length more than 900mm to enable the third chuck, if less than 900mm, the third chuck will be idle

2. Once to have the 0 tailing material cutting, it maybe have precision lost once to cut the diameters less than 100mm by its long distance from the bottom part to the clamps

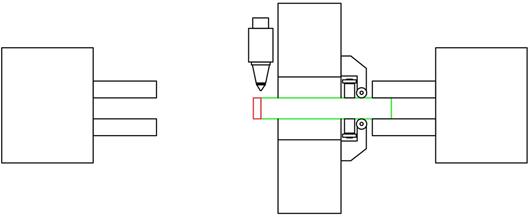

1. The problems in heavy duty pipe cutting

Once to cut heavy duty pipes, the green parts as the above picture shown hanging too long, the self- weight will have a big leveraging force which can not neutralize by the clamps. the hanging pipes will lower down, and also slips from the clamps once feed forth and back to have a result of fault cutting

Also can not solve this kind of problems by floating support

After above points, so maybe we can very easy to know the advantages and disadvantages for the 3 chucks, we need to understand the customers need firstly

3 chucks are definitely a good choice but the cost is also definitely higher by adding an extra chucks

Above is the basic details for the tubes, actually in real productions, it is more complicated by its different requirement

1) If the tubes are not straight, is it possible to cut and how can also make sure the precision?

2) Normally the tubes have welding lines, is it possible to avoid the welding lines?

3) Is it possible to make sure the inner surface clean once to cut the stainless steel which is used for the food industry?

4) Bevel cutting in China is stable or not if to compare with BLM Italy

5) Auto loader is suitable for all the tubes? And if heavy duty tubes, how to load the tubes and how to unload the tubes?

6) 4 chucks tube cutting machine are really necessary?

7) More and more questions are there

Remcor, a professional supplier with 18 years experiences in the laser industry, we can provide the turnkey lines for the laser cutting lines by importing the completed lines such as milling machines, CNC machining centers etc.

We are glad to get your any inquiries, and looking for the distributor globally, thanks.

This is the last one.