Jan 29 , 2023

Thank you for choosing the Remcor three-in-one system. This user manual provides you with important safety, operation, maintenance and other information. Therefore, before using the 3 in 1 laser welding machine, please read this user manual carefully. To ensure safe operation and optimum product operation, please observe the following cautions and warnings and other information in this manual.

Handy laser welding cleaning cutting is the trend to replace the TIG, and MIG welder, faster welding speed, better welding performance, and strong quality which is more and more popular in China

The handheld fiber laser welding machine has 3 functions cutting, cleaning, and welding by using the same head, which can cut metal, can weld metal, and also can clean the rust, oil, painting etc.

Which features movable, easy to handle, several times higher welding efficiency and also cleaning efficiency etc.

So it is recommended by our fiber laser welding machine supplier and it is your right choice to have a try.

This manual covers general descriptions of the SUP series system, including basic installation, factory settings, operation and maintenance services, etc. The latest system that rolled out by our company can support handheld laser welding, laser cleaning, and laser cutting at the same time. The system will switch its operating mode flexibly due to different application scenarios, providing diversified solutions for users' different application requirements. The product, equipped with multiple safety alarms and active safety power and light cut settings, covers welding heads/cleaning heads and a self-developed control system.

The product is developed on the basis of the hand-held welding heads that our company has produced in large quantities, which makes it reliable and stable. The product can be adapted to various brands of fibre lasers. Meanwhile, the laser head can work stably for a long time under 2000W because of the optimized design of the optics and water cooling.

Features:

● Basic features: The product with a self-developed three-in-one control system can

be flexibly switched the mode of welding, cleaning, and cutting. It sets up multiple security alarms and can be operated easily and flexibly.

● More stability: All parameters are visible and the status of the whole machine will be monitored in real time, so that we can avoid problems in advance and troubleshoot

and resolve issues easily to make sure that the system can work stably.

● Craft: Craft parameters can be set, and various craft effects can be tried flexibly.

● Stable parameters and high repeatability: Nozzle Air Pressure and Lens Status will be determined,.In this case,as long as the power of the laser is stable, the craft parameters must be repeatable, which greatly improves efficiency.

The system provides clients with several options for the different application requirements. The following are these options.

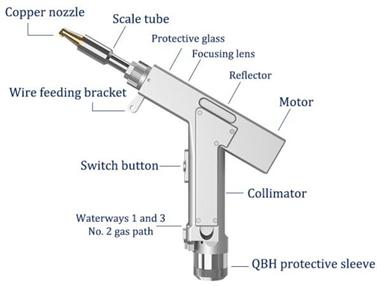

Option One: Handheld Laser Welding Head (SUP20T) + three-in-one system control box + display screen.

This matching option is to directly use the hand-held laser welding head (SUP20T) to realize welding, cleaning and cutting. The advantages of this solution are economical and convenient to use, but the disadvantage is that the scanning width is narrow during cleaning and the cleaning efficiency is average.

Table 1.1 shows the operating environment requirements and main parameters of the handheld laser welding head (SUP20S):

Table 1.1 Operating environment requirements and main parameters of Scheme 1

Supply voltage (V) | 220V±10% AC 50/60Hz |

Place the environment | Flat, no vibration and shock |

Working environment temperature (℃) | 10~40 |

Working environment humidity (%) | <70 |

Cooling method | Water cooling |

Applicable wavelength | 1064nm(±10nm) |

Applicable power | ≤2000W |

Collimation | D20*5/F60 |

Focus | D20*4.5/F150 |

Reflection | 30*14 T2 |

Protective lens specifications | 18*2 |

Maximum supported air pressure | 10Bar |

Focus vertical adjustment range | ±10mm |

Spot adjustment range (handheld welding mode) | 0~6mm |

Weight | 0.8kg |

Option Two: Handheld laser welding head (SUP20S) + F400 focusing lens + three-in-one system control box + display screen.

This kind of matching scheme is: directly use the handheld laser welding head (SUP20S) to realize welding, cleaning and cutting, but when used for cleaning, replace the F150 focusing lens that comes with the SUP20S with the F400 focusing lens. The advantage of this scheme is that it is more economical and convenient, and the scanning width can reach 50mm during cleaning, which is higher than the first scheme in cleaning efficiency.

The operating environment requirements and main parameters of this program equipment are shown in Table 1.2:

Table 1.2 Operating environment requirements and main parameters of Scheme 2

Supply voltage (V) | 220V±10% AC 50/60Hz |

Place the environment | Flat, no vibration and shock |

Working environment temperature (℃) | 10~40 |

Working environment humidity (%) | <70 |

Cooling method | Water cooling |

Applicable wavelength | 1064nm(±10nm) |

Applicable power | ≤2000W |

Collimation | D20*5/F60 |

Focus (handheld welding mode) | D20*4.5/F150 |

Focus (cleaning mode) | D20*4.5/F400 |

Reflection | 30*14 T2 |

Protective lens specifications | 18*2 |

Maximum supported air pressure | 10Bar |

Focus vertical adjustment range | ±10mm |

Spot adjustment range (handheld welding mode) | 0~6mm |

Spot adjustment range (cleaning mode | 0~50mm |

Weight | 0.8kg |

Option Three: Handheld laser welding head (SUP20S) + special cleaning head (SUP20C) + three-in-one system control box + display screen.

The operating environment requirements and main parameters of the handheld laser welding head SUP20S are shown in the handheld welding mode in Table 1.1.

The operating environment requirements and main parameters of the special cleaning head SUP20C are shown in Table 1.3:

Table 1.3 Operating environment requirements and main parameters of special cleaning heads.

Supply voltage (V) | 220V±10% AC 50/60Hz |

Place the environment | Flat, no vibration and shock |

Working environment temperature (℃) | 10~40 |

Working environment humidity (%) | <70 |

Cooling method | Water cooling |

Applicable wavelength | 1064nm(±10nm) |

Applicable power | ≤2000W |

Collimation | D20*5/F60 |

Focus | D20*4.5/F400 |

Reflection | 30*14 T2 |

Protective lens specifications | 18*2 |

Maximum supported air pressure | 10Bar |

Focus vertical adjustment range | ±10mm |

Spot adjustment range | 0~150mm |

Weight | 0.8kg |

Before supplying power, ensure that the shell of the whole machine is reliably grounded.

The laser output head is connected to the welding head. Please check the laser output head carefully when using it to prevent dust or other pollution. When cleaning the laser output head, please use special lens paper.

If the equipment is not used in accordance with the methods specified in this manual, it may be in an abnormal working state and cause damage.

When replacing the protective lens and focusing lens, please make sure to protect it.

Please note: When using for the first time, when the red light cannot come out of the copper nozzle, be sure not to press the trigger to emit light.

Plug | Definition | Signal type | Detailed explanation |

Power supply | 1 | -15V | Enter | Connect to V2 of ±15V switching power supply, provide -15V power supply voltage | |||

2 | GND | Reference place | Connect to any COM switching power supply | of ±15V | |||

3 | +15V | Enter | Connect to V1 of ±15V switching power supply, provide +15V power supply voltage | ||||

4 | GND | Referen ce place | -V connected power supply | to | 24V | switching | |

5 | +24V | Enter | +V connected power supply | to | 24V | switching | |

LCD screen | 1 | G | Referen ce place | Power ground | |||

2 | R | Sender | Data direction: controller → LCD screen | ||||

3 | T | Receivin g end | Data direction: screen→controller | LCD | |||

4 | V | Output | Provide 24V power supply for LCD screen | ||||

Signal interface 1 | 1 | GND | Referen ce place | Signal ground | |||

2 | Air pressure alarm signal | Enter | The polarity of the alarm signal can be set on the setting page, and set to low level alarm when not in use | ||||

3 | GND | Referen ce place | Signal ground | ||||

4 | Water cooler alarm signal | Enter | The polarity of the alarm signal can be set on the setting page, and set to low level alarm when not in use | ||||

5 | Securely lock the reference ground | In isolation | Welding mode: connect the processed workpiece and form a loop with 6 feet to prevent accidental light emission. Cleaning mode: The interface is suspended, and no judgment is made inside the software. | ||||

6 | Safely lock | Enter | Welding mode: connect the blue wire of the three-core wire of the welding head. Cleaning mode: The interface is suspended, and no judgment is made inside the software. | ||||

7 | Welding head light switch 1 | Referen ce place | The brown wire of the three-core wire connected to the welding head. | ||||

8 | Welding head light switch 2 | Enter | The blue wire of the three-core connected to the welding head. | wire | |||

Signal interface 2 | 1 | Reserved input | Enter | Reserved | |||

2 | Reserved output | Output | Reserved (synchronized with 4 foot air valve signal) | ||||

3 | Protection valve- | Referen ce place | Signal ground (reference ground of pin 2/4) | ||||

4 | Protection valve+ | Output | Air valve open: output 24V; Air valve closed: no output. | ||||

5 | Wire feed- | Welding mode: The wire feed switch signal of the wire transfer machine, regardless of positive or negative. Cleaning mode: no wire feeding is required, and the interface is suspended. | |||||

6 | Wire feed+ | ||||||

Signal interface 3 | 1 | Laser signal | abnormal | Enter | Laser alarm signal | ||

2 | Laser enable | light | Output | Enable signal of laser | |||

3 | 24V output | Output | 24V output, directly voltage after power on. | output | 24V | ||

4 | GND | Referen ce place | Reference ground (reference ground for pin 1/2/3/5) | ||||

5 | 0 ~ 10V analog quantity | 0 ~ 10V analog quantity | Connect to the analog quantity of the laser DA+ | ||||

6 | RF-(PWM-) | Output | Laser pulse width modulation signal- | ||||

7 | RF+ (PWM+) | Output | Laser pulse width modulation signal+ | ||||

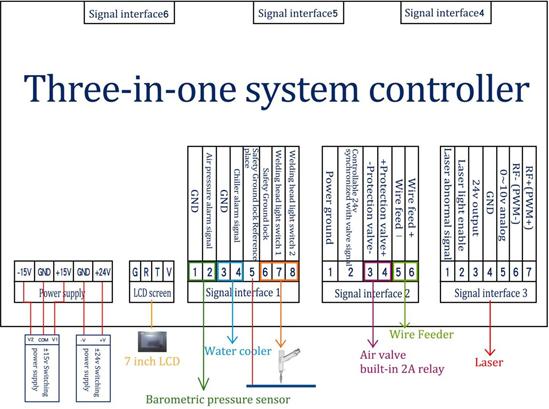

2.1.1 Controller power supply terminal

The power supply terminal uses a 5P interface, and the supplied 24V switching power supply and ±15V switching power supply are used for power supply.

Please note that the 15V switching power supply distinguishes the positive and negative poles, V1 is connected to +15V, V2 is connected to -15V, and any COM on the 15V switching power supply is connected to pin 2 GND!

Please note that the switching power supply must be grounded!

2.1.2 Controller LCD screen

The wiring of the LCD screen is included with it, and it can be connected directly. The specific definition is shown in Table 2.1 above.

2.1.3 Controller signal interface 1

The signal interface 1 uses the 8P interface, which is the input signal interface.

Signal interface 1 | ||

Pin number | Signal definition | Function Description |

1 | GND | If you need to enable the air pressure alarm signal input port (wiring is required), please set the "air pressure alarm level" on the setting page of the display to the same level as the actual air valve alarm level. |

2 | Air pressure alarm signal | |

3 | GND | If the water tank alarm signal input port needs to be enabled (wiring is required), please set the "water cooler alarm level" on the display setting page to be consistent with the actual water cooler alarm level. |

4 | Water tank alarm signal | |

5 | Securely lock the reference ground | Welding mode: directly connected to the workpiece. Cleaning mode: The interface is suspended, and no judgment is made inside the software. |

6 | Safely lock | Welding mode: The safety ground lock of the welding head is connected to the blue wire of the three-core wire. When the welding head touches the workpiece, the safety ground lock on the screen lights up. Cleaning mode: The interface is suspended, and no judgment is made inside the software. |

7 | Welding head light switch 1 | Connect the brown wire of the three-core wire. |

8 | Welding head light switch 2 | Connect the black wire of the three-core cable. When the trigger is pulled, the trigger button on the screen will be on. |

Note: Please note that only when there is no alarm, and the safety lock and switch signal are displayed in green, the subsequent output ports will have normal output signals. | ||

2.1.4 Controller signal interface 2

The signal interface 2 uses the 6P interface, and the detailed function definition is shown in Table 2.3:

Table 2.3 Function description of signal interface 2

Signal interface 2 | ||

Pin number | Signal definition | Function description |

1 | Reserved input | Reserved pin |

2 | Reserved output | |

3 | Protection valve- | Air valve open: protection air valve + 24V output; Air valve closed: protective air valve + no output. |

4 | Protection valve+ | |

5 | Wire feed- | Welding mode: The wire feed switch signal of the wire transfer machine, regardless of positive or negative. Cleaning mode: no wire feeding is required, and the interface is suspended. |

6 | Wire feed+ |

2.1.5 Controller signal interface 3

The signal interface 3 uses the 7P interface, and the detailed function definition is shown in Table 2.4:

Table 2.4 Function description of signal interface 3

Signal interface 3 | ||||||||

Pin number | Signal definition | Function description | ||||||

1 | Laser Abnormal Signal | If you need to enable it (wire connection is required), please set the "Laser Alarm Level" on the screen setting page to be consistent with the actual laser alarm level. | ||||||

2 | Laser enable | light | Enable +, connect to the enable + of the laser. | |||||

3 | 24V output | 24V output, directly output 24V voltage after power on. | ||||||

4 | GND | Common 1/2/3/5) | ground | (reference | ground | for | pin | |

5 | Analog + | Analog output (default is 0~10V analog voltage). | ||||||

6 | RF-(PWM-) | PWM-modulated signal | ||||||

7 | RF+ (PWM+) | PWM+ modulation signal | ||||||

The wiring of the three-in-one controller is slightly different in different modes,

Figure 2.1 Wiring diagram of welding mode controller

SUP welding head is suitable for most industrial laser generators. Commonly used fiber connectors include IPG, Ruike, Chuangxin, Fibo, Tottenham, Jept, Kaplin, etc. The optics must be kept clean, and all dust must be removed before use. The torch head must be placed horizontally when the optical fiber is inserted to prevent dust from falling into the interface.

Installation method

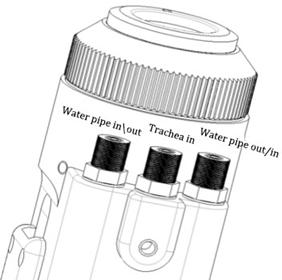

The water pipe and air pipe interface can be installed with hoses with an outer diameter of 6mm and an inner diameter of 4mm. The middle is the gas inlet, and the two sides are the water inlet and outlet pipelines (regardless of the inlet and outlet directions), as shown in the following figure:

Figure 2.2 Schematic diagram of water pipe and air pipe

The cooling system is divided into the water circuit part of the welding head and the water circuit part of the optical fiber head, which are connected in series, as shown in the figure below:

The welding gun and the control box use three wires to connect, including: two-core motor power cord, five-core motor signal line, and three-core safety lock and trigger button line.

The version number of the control panel of the three-in-one system is 532. You can check the system version through the monitoring page. The last three digits indicate the version of the control panel.

(1) Front page

On this interface, you can see the current process parameters (the process cannot be modified on this page) and real-time alarm information.

When the power is on The enable default is ON, indicating that the red light defaults to LINE, and the welding mode is continuous.When the enable is turned off, the enable signal will not be sent to the laser, which can be used to test the gas outlet function. Turn off the red light indicator and the motor stops swinging. At this time, the red light is a point for adjusting the center position. The welding mode is divided into continuous and spot welding. When spot welding is selected, the spot welding type needs to be set on the setting page.

The safety lock is divided into gray and green. When the 5 and 6 pins of the signal interface 1 are short-circuited, the display is green. At this time, the light can be emitted by controlling the signal pin "welding head light switch 1, 2".

Upper right corner orange The button is a switch button,Click to switch to the cleaning mode selection interface.

(2) Craft page

Scanning speed range: 2~6000mm/s;

Peak power range: 1W~xW, x is the laser power on the setting page;

Duty cycle range: 0~100%, the default setting is 100%, usually no need to change; Pulse frequency range: 5~100000Hz, 5~5000Hz is recommended; Precautions:

The process interface contains the process parameters for debugging. There are a

total of 10 processes that can be saved in this version.

The parameters of the craft page can be modified, click the input box to modify, click OK after modification, and then save, and click import when using it (modify-save-import).

Some lasers cannot emit light with a power lower than 10%. When the peak power of the craft page is less than 10% of the maximum power of the laser on the setting page, all output signals are normal, but light may not be emitted.

The duty cycle is 100% by default, and usually does not need to be changed. At this time, the pulse frequency does not work. If you need to use it, please adjust it according to actual needs. Example: 300W peak power, 50% duty cycle, and 1000Hz pulse frequency. At this time, the light emission period is 1mS, 0.5mS emits light at 300W, 0.5mS does not emit light, and it cycles back and forth. At this time, the airblasts at the welding place and abnormal noise is normal. The actual situation is subject to the laser parameters.

Click the "Help" button at the top right of the screen to get more related parameter explanations.

More reference crafts can be viewed in the craftsmanship of the WeChat applet.

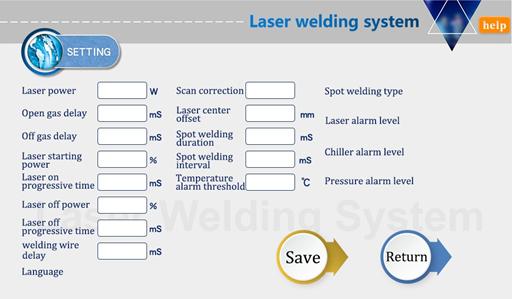

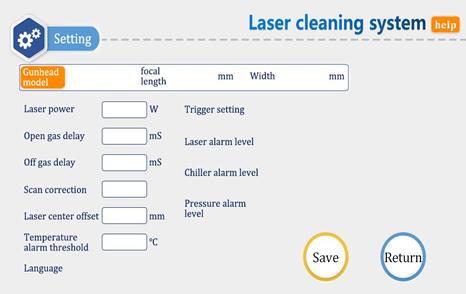

(3) Settings page

Click "Settings" on the home page, and enter the password 123456 on the password input page of the pop-up window to enter the settings page.

The laser power is the maximum power calibrated by the laser manufacturer used. Please fill in it correctly.

The switch air delay defaults to 200ms, and the range is 0ms~3000ms.

Example: Set the air-on delay to 1000ms, and the air-off delay to 500ms. The actual effect is that when the trigger is pressed, the breath lasts for 1000ms and then the light is emitted. Release the trigger, after the laser stops emitting light, continue to vent for 500ms and then stop venting.

Reasonable setting of the switch gas delay can well protect the molten pool from oxidation and prevent slag return from damaging the lens.

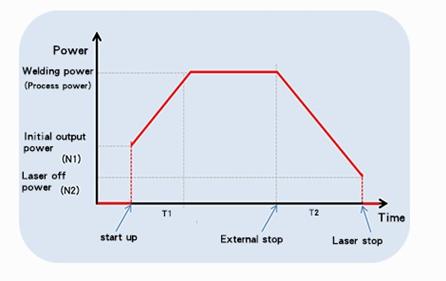

When the light is turned on, the process power is gradually increased from N1 to 100%; when the light is turned off, it is gradually increased from 100% of the process power to N2; (as shown in the figure below):

Generally, the preset switching optical power is 20%, and the switching optical progressive time is 200ms;

Wire feeding delay compensation is the wire feeding advance time relative to the light signal. It can be used in conjunction with the withdrawal function, and it is not set by default;

The maximum temperature alarm threshold is 65℃, when the value is set to 0, no temperature alarm will be detected;

Scan correction coefficient = target line width/measurement line width, range 0.01~4. Generally set to 1;

Laser center offset -3~3mm, reduce it and move it to the left, increase it and move it to the right, it is used to adjust the red light center of the axis;

The air pressure/water cooler/laser alarm level signal defaults to low level. When this alarm signal is used, the alarm level here needs to be set to be consistent with the alarm level of the external device;

Spot welding duration is the light emission time in each cycle in the spot welding mode, and the spot welding interval time is the stop light time in each cycle in the spot welding mode;

Click the "Language" box in the lower left corner to switch the interface language. The current version supports Chinese, English, Korean, and Russian. Click the "Help" button at the top right to get more related parameter information.

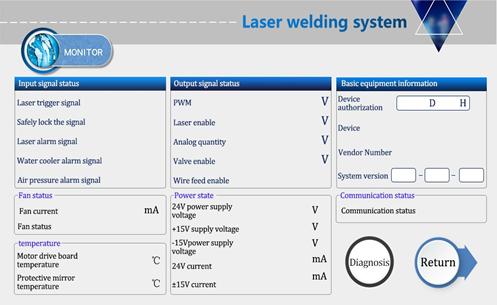

(4) Monitoring page

This page displays the status of each signal and device information. Please note that this monitoring interface is only displayed when the setting interface is in Chinese, otherwise it is a monitoring page of other versions.

(1) Input signal status

Laser trigger signal: Press the hand-held welding trigger, the 7 and 8 pins of the signal interface 1 are turned on, and the status changes from gray to green to take effect.

Safely lock signal: safely clamp on the workpiece. When the copper nozzle of the gun head touches the workpiece, the status will change from gray to green to take effect. Laser/water cooler/air pressure alarm signal: monitor the real-time level status input from these interfaces.

(2) Output signal status

When the signal is output, the signal in this area changes immediately and can be directly visualized. The monitoring signal is a real-time detection circuit signal, which fluctuates within a certain range and has an error of less than 0.3V from the final output signal.

(3) Basic equipment information

Device authorization: The device can be authorized for the duration of use. When the device is used for more than the set time, the authorization is displayed as terminated. The factory default authorization is valid for a long time. If you need encryption and decryption, please contact our company for inquiries.

(4) Diagnosis

The communication between the touch screen and the main board is displayed. If there is no synchronization, check the screen connection line.On the monitoring interface, click the "Diagnosis" button to enter the diagnosis interface. No light will be emitted at this time, and it is used to measure whether each signal port has an actual output, usually the output value is consistent with the detection value. When it is inconsistent, the load is abnormal, such as when the laser does not emit light, by switching a single port and using the laser monitoring software or multimeter to measure, it can truly reflect whether the signal is sent out.

Figure 3.2.1 Welding Home Page

Figure 3.2.2 Switch page Click the switch button on the welding home page to enter the transition page.

In the same way, you can switch from cleaning mode back to welding mode.

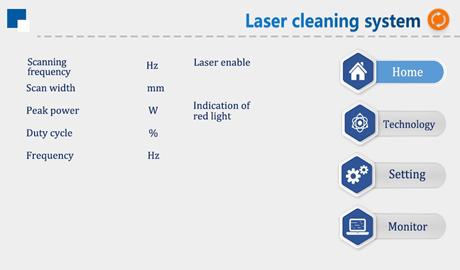

3.3.1 Front page

①On this interface, you can see the current process parameters (the process cannot be modified on this page) and real-time alarm information.

②When the power is on The enable default is ON, indicating that the red light defaults to LINE.When the enable is turned off, the enable signal will not be sent to the laser, which can be used to test the gas outlet function. Turn off the red light indicator and the motor stops swinging. At this time, the red light is a point for adjusting the center position.

③This mode no longer detects the safety lock signal, so there is no need to modify the wiring after switching the mode.

④Upper right corner orange The button is a switch button,Click to switch to the welding mode interface.

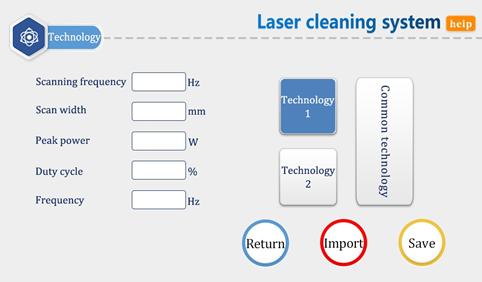

(2) Craft page

Scanning frequency range: 0~100Hz;

Scanning width range: 0~20mm/50mm/150mm, the maximum width is selected according to the gun body and focusing lens model. See the model selection page for details.

Peak power range: 1W~xW, x is the laser power set on the setting page;

Duty cycle range: 0~100%, the default setting is 100%, usually no need to change; Pulse frequency range: 5~100000Hz, 5~5000Hz is recommended;

Precautions:

The process interface contains the process parameters for debugging. A total of 3 processes can be saved in this version.

2×scanning frequency×scanning width=actual scanning speed. Maintaining the same scanning frequency can ensure a relatively uniform scanning trajectory under different scanning widths.

The parameters of the craft page can be modified, click the input box to modify, click OK after modification, then save, and click import when using it (modify-save-import).

Some lasers cannot emit light with a power lower than 10%. When the peak power of the craft page is less than 10% of the maximum power of the laser on the setting page, all output signals are normal, but light may not be emitted.

The duty cycle is 100% by default, and usually does not need to be changed. At this time, the pulse frequency has no effect. If you need to use it, please adjust it according to actual needs. Example: 300W peak power, 50% duty cycle, and 1000Hz pulse frequency. At this time, the light emission period is 1mS, 0.5mS emits light at 300W, 0.5mS does not emit light, and it cycles back and forth. At this time, the air blasts at the welding place and abnormal noise is normal. The actual situation is subject to the laser parameters.

Click the "Help" button at the top right of the screen to get more related parameter explanations.

For more reference crafts, you can check the craftsmanship of the WeChat applet.

(3) Settings page

Click "Settings" on the home page, and enter the password 123456 on the password input page of the pop-up window to enter the settings page. Compared with the welding mode, the setting page of the cleaning mode has deletedsomeparameters that are not used for cleaning, and added two parameters dedicated to cleaning, "Tip Type" and "Trigger Setting".

The laser power is the maximum power calibrated by the laser manufacturer used, please fill it in correctly;

The default delay of switch gas is 200ms, and the range is 0ms~3000ms;

The scan correction default is 1, and the range is 0.1~4. "Scan correction" × "scan width" of the craft page = actual scan width at the focal point (±3mm);

The laser center offset is 0mm by default, and the range is -75mm ~ +75mm. Decrease to move to the left, increase to move to the right, applied to adjust the axis of the red light center;

The temperature alarm threshold is 65°C by default, and the alarm is invalid when it is set to 0°C.

Trigger setting: When you select double-click, press the trigger twice to emit light, which can prevent accidental touch. Press the trigger once when you choose to click to emit light.

The air pressure/water cooler/laser alarm level signal defaults to low level. When this alarm signal is used, the alarm level here needs to be set to be consistent with the alarm level of the external device;

"Tip Type" Click the orange area to enter the model selection page, and select the corresponding scan width according to the specific model. If the width does not match the model, the laser may hit the inside of the gun body and damage the product.

(4) Scan width selection page

"SUP20S-150mm focal length-20mm width" corresponds to the factory default

This system does not have a professional cutting mode. Based on the actual power of the laser, the welding mode can be used for thin plate cutting.

When you need to use the cutting function, please replace the cutting copper nozzle and set the scan width to 0mm.

How to maintain and replace protective lenses:

Before operation, please clean your hands and wipe them dry, and then wipe your hands again with cotton dipped in alcohol.

Remove the screws of the protective lens compartment cover in a relatively dust-free place, pull out the protective lens bracket, and protect it (covered by

masking paper). Check the protective lens. If there is obvious burning on the surface of the protective lens, replace it directly.

Then check the white accumulating sealing ring under the protective lens. (If there is any scratch or deformation of the accumulating seal ring, it cannot be used and must be replaced immediately.

Wipe the compartment opening and the inside of the compartment cover with a cotton ball dipped in alcohol, quickly insert the protective lens holder into the protective lens compartment, and tighten the screws.

If the above alarm occurs without using the alarm signal, please change the alarm level on the screen setting page.

If the above alarm occurs when the alarm signal is used, check whether the alarm of the corresponding equipment or the high and low levels of the alarm signal are set incorrectly.

If the screen is not on, make sure that the controller is powered on, and check whether the four-core wire between the controller and the screen is correctly wired, and whether the 24V voltage of pin 1 and pin 4 is normal.

If the click does not work during normal use, check whether the temperature of the whole machine is too high.

Tap Cannot input, check whether the four-core wire between the controller and the screen is correctly wired, and whether the second and third pins are normal. For details, see 2.1.2 on the display of the controller.

There is no response when clicking on the newly installed device. It may be that the system version does not match, just use the SD card to re-swipe the program. Please consult our company for the specific version.

Check whether there is an alarm prompt on the homepage and whether the laser enable is ON;

Check whether the trigger signal and safety lock signal on the monitoring page are displayed in green when welding;

Check whether the PWM, laser enable, and analog output on the monitoring page are normal during welding.

If the above status is normal, please check whether the laser has abnormal alarm. Example: The air is fed and the wire is fed but the light is not emitted, which is because the laser is faulty or the laser wiring is wrong. If neither the air is vented nor the wire is fed, the input signal may be missing. For details, see: 2.1.3 Controller signal interface 1.