Jan 29 , 2023

Nowadays, the fiber laser cutting machine has become one of the most important and widely used tools in the sheet metal fabrication industry. Compared with traditional plasma cutting machines and CO₂ laser cutting machines, fiber laser cutting technology offers significantly higher cutting speed, better energy efficiency, lower maintenance cost, and superior cutting edge quality. As a result, fiber laser cutting machines are rapidly replacing older cutting technologies across global markets.

In recent years, high-power fiber laser cutting machines (10kW and above) have become a clear industry trend. Higher laser power enables:

Faster cutting speed

Better cutting performance on thick materials

Improved edge smoothness and verticality

However, despite these advantages, the total investment cost of high-power laser cutting machines is still not affordable for many customers, especially small and medium-sized manufacturers.

Therefore, low-power and medium-power fiber laser cutting machines remain the main driving force of the market.

Most Popular Power Configurations in the Market:

1500W fiber laser cutting machine – Entry-level, suitable for thin sheet metal

2000W laser cutting machine – Stable choice for light industrial use

3000W fiber laser cutting machine – Most popular and cost-effective option

6000W fiber laser cutting machine – Ideal balance between speed, thickness, and investment

Among these, 3000W and 6000W fiber laser cutting machines are currently the most widely accepted configurations worldwide.

No matter:

Which CNC system is used

Which laser cutting head is installed

Which fiber laser source brand is selected

The most critical factor for customers is always the cutting edge quality across different material thicknesses and materials.

If the cutting edge is not acceptable—such as having burrs, slag, burn marks, or poor perpendicularity—the operator must continuously adjust parameters until a satisfactory result is achieved.

In real applications, we often find that not all customers can fully utilize even a low-power laser cutting machine.

Common issues include:

Poor cutting edge quality

Excessive burrs at the bottom of the cut

Cutting speed much slower than expected

Inconsistent cutting results between operators

Sometimes one customer achieves excellent results, while another customer with similar equipment struggles to get acceptable performance.

Laser cutting is a complex process, and achieving a perfect cutting edge requires multiple test runs. The final cutting result is determined by a combination of machine precision, parameter settings, material condition, and operator experience.

It is not a one-click process.

To obtain the best cutting edge and cutting efficiency, the following parameters must be carefully adjusted and optimized one by one:

Focus Position

Positive focus, zero focus, or negative focus

Directly affects kerf width and edge smoothness

Assist Gas Type

Oxygen (carbon steel)

Nitrogen (stainless steel, aluminum)

Air cutting for cost reduction

Gas Pressure

Too low: slag and burrs

Too high: unstable cutting and rough edges

Nozzle Size and Nozzle Type

Single-layer vs. double-layer nozzle

Nozzle diameter must match thickness and power

Cutting Speed

Too fast: incomplete cutting

Too slow: burn marks and excessive heat input

Laser Power Setting

Stainless steel: usually close to or at full power

Carbon steel: adjustable from 10% to 90% of full power to achieve the best edge

Piercing Method and Piercing Time

Proper piercing avoids splash, deformation, and poor start points

Many customers contact us with similar concerns:

“Why does my laser cutting edge have so many burrs?”

“Is it possible to cut faster with the same thickness?”

“Why is my fiber laser cutting machine not working at optimal conditions?”

In most cases, the solution is systematic parameter re-testing and fine-tuning, combined with manufacturer technical support.

A reliable laser cutting machine manufacturer should not only supply the equipment, but also:

Provide cutting parameter databases

Assist with on-site or remote testing

Offer real cutting samples for reference

Share application experience from different industries

This support is especially critical for 1500W, 2000W, 3000W, and 6000W fiber laser cutting machines, where parameter precision directly determines performance.

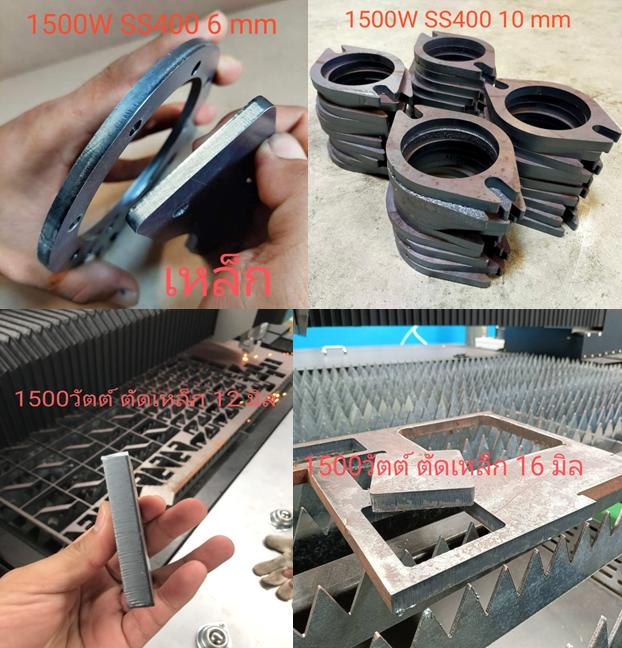

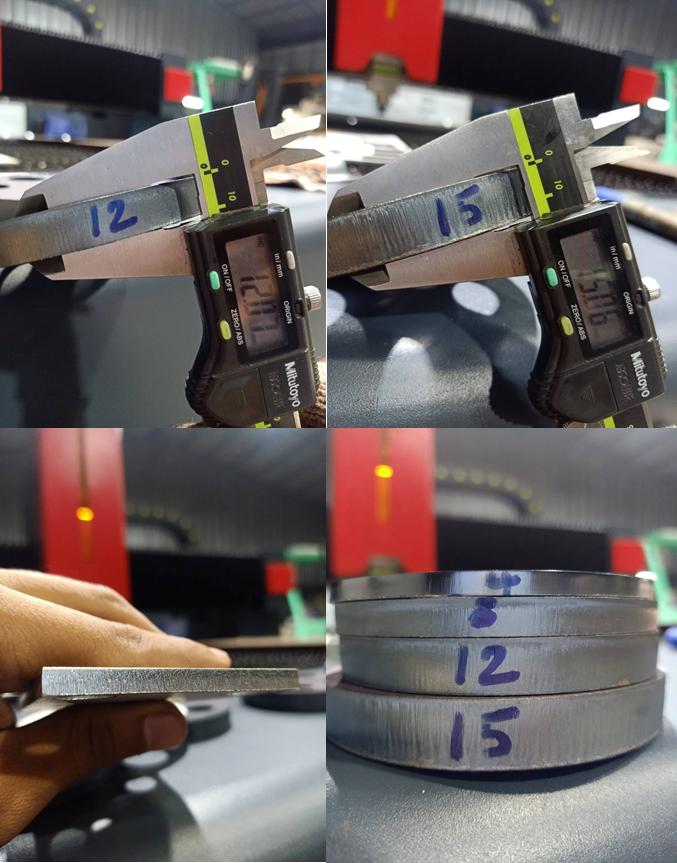

This time, we would like to present actual cutting samples from 1500W to 6000W fiber laser cutting machines, which are directly provided by our customers.

These samples are for reference only, but they clearly demonstrate:

Cutting edge quality differences at various power levels

Material thickness capability

Real-world cutting performance under practical conditions

The fiber laser cutting machine is now the mainstream solution in the sheet metal industry. While high-power laser cutting continues to grow, 3000W and 6000W fiber laser cutting machines remain the most practical and cost-effective choices for most users.

Ultimately, cutting quality is not determined by power alone, but by a well-balanced combination of:

Proper machine configuration

Accurate parameter settings

Skilled operator experience

Strong manufacturer support

Only by mastering all these elements can customers fully unlock the true value of their laser cutting machine.

Material: Carbon Steel

Maximum Cutting Thickness: Up to 16mm

Cutting Edge Quality:

Clean surface

Minimal burrs

Stable kerf and consistent results

This demonstrates that a 1500W fiber laser cutting machine is fully capable of handling many standard sheet metal applications, especially for customers mainly working with thin to medium thickness materials.

2000W Cutting Samples Overview

For the 2000W laser cutting machine, we normally configure it with the Raytools BM111 laser cutting head, which is widely used and optimized for 2000W–3000W fiber laser cutting machines.

Key Characteristics of 2000W Laser Cutting:

Cutting Capability:

Almost the same thickness range as 1500W

Main Advantage:

Higher cutting speed compared with 1500W

Application Scenario:

Customers who require better productivity but still focus on thin and medium plates

In summary, the 2000W laser cutting machine offers improved efficiency while maintaining stable and reliable cutting quality.

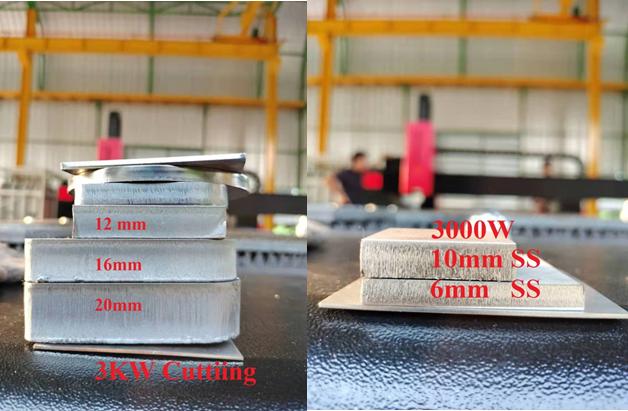

From the cutting sample images, we can clearly observe that:

Carbon Steel 20mm:

Much better cutting edge quality

Straighter kerf and smoother surface

Thin Materials:

Bright, shining cutting edge

Stainless Steel 10mm:

Excellent edge quality

Clean cut without secondary processing

Because of these advantages, the 3000W fiber laser cutting machine is widely recognized as the best cost-performance solution in the market.

Why 3000W Is Enough for Most Customers:

Over 70% of the sheet metal market focuses on thin materials

More than 90% of customer requirements can be covered by 3000W

Balanced performance between:

Cutting thickness

Cutting speed

Equipment investment

That is why the 3000W fiber laser cutting machine has become one of the most popular configurations worldwide.

Although low and medium power machines cover most applications, some customers still require higher laser power.

The main reasons include:

Cutting thicker carbon steel (e.g., 25mm or above)

Achieving higher cutting speed on medium and thick plates

Increasing production efficiency for heavy-duty applications

For these customers, 4000W and 6000W laser cutting machines become a necessary upgrade.

We would also like to share our 6000W fiber laser cutting machine samples, which we believe represent the most popular choice in the medium-power segment.

6000W Cutting Performance Highlights:

Carbon Steel Cutting Thickness:

Up to 25mm with a good cutting edge

Edge Quality:

Smooth, stable, and consistent

Efficiency:

Significantly higher cutting speed than 3000W and 4000W

6000W vs. 4000W Laser Cutting Machine:

6000W offers:

Higher maximum cutting thickness

Better edge quality on thick carbon steel

Faster cutting speed and higher productivity

As a result, the 6000W laser cutting machine has become a preferred solution for customers who need both thickness capability and production efficiency.

Remcor Technology, which have 18 years experiences in the laser industry, which have fiber laser cutting machines, wholesale laser cleaning machine, fiber laser cleaning machines, automatic panel bender, and pivatic type punching lines etc.

We are not only to offer our machines, we are more glad to hear your feedback and create the values for your company to get a win-win situation.