Jan 29 , 2023

Nowadays, high power laser cutting machine is not as secret yet as before, and also so many customers are starting to try high-power laser cutting machines, but why we choose high power laser cutting machines?

We need to admit that it really has a lot of advantages by high-power laser cutting machines, As an obvious result, we can have a higher cutting speed to get a lower cost per part, and also the higher cutting capability and more beautiful edge if we use high power.

Stainless Steel (3000-15000W)

Thickness(mm) | 3kw(m/min) | 6kw | 12kw | 15kw |

1 | 40 | 70 | 80 | 80 |

3 | 8.5 | 16 | 30 | 34 |

4 | 6 | 12 | 24 | 28 |

8 | 1.1 | 4 | 11 | 14 |

12 | 0.5 | 1.2 | 5.0 | 7.5 |

16 | --- | 0.9 | 2.5 | 4.5 |

20 | --- | 0.45 | 1.5 | 2.6 |

Aluminum N2 cutting 6KW-15KW | |||||||

Alu.(N2) | 6KW | 8KW | 10KW | 12KW | 15KW | 15KW/12KW | |

4 | 10 | 20 | 25 | 28 | 50 | 78.6% | |

5 | 8 | 15 | 17 | 20 | 36 | 80% | |

6 | 5.5 | 9 | 9.5 | 11 | 18 | 64% | |

10 | 1.3 | 3 | 4.5 | 5 | 6.8 | 36% | |

16 | 1.2 | 1.3-1.5 | 1.6 | 2.3 | 44% | ||

20 | 0.9 | 1 | 1.2 | 1.6 | 33% | ||

25 | 0.5 | 0.7 | 0.8 | 1 | 25% | ||

30 | 0.3 | 0.45 | 0.55 | 0.7 | 27% | ||

40 | 0.3 | 0.3 | 0.55 | 83% | |||

50 | 0.2 | ||||||

Mild Steel(O2)

Thickness(mm) | 6kw | 10kw | 15kw |

12 | 1.3 | 2.5 | 2.5 |

16 | 0.8 | 1.8 | 1.8 |

20 | 0.6 | 1.3 | 1.4 |

25 | 0.26 | 0.6 | 1.2 |

30 | --- | 0.45 | 0.85 |

35 | --- | 0.30 | 0.5 |

40 | --- | --- | 0.3 |

50 | --- | --- | 0.26 |

N2/air cutting mild steel, Speed X 2-7.6 faster

Thickness(mm) | 4kw (O2/N2) | 6kw | 8kw | 10kw | 12kw | 15kw |

2 | 6.5/23 | 6.5/30 | 6.5/30 | 6.5/30 | 6.5/30 | 6.5/32 |

4 | 3.6/7.8 | 3.8/13 | 3.8/18 | 3.8/22 | 3.8/25 | 3.8/29 |

8 | 2.6 | 2.3/4.5 | 2.7/6.5 | 2.7/8 | 2.7/9 | 2.7/12 |

10 | 2.1 | 2.4 | 2.4/4.2 | 2.4/5.5 | 2.4/7 | 2.4/8.5 |

16 | 0.8 | 1.5 | 1.6 | 1.6 | 1.8 | 1.8/3.5 |

20 | 0.7 | 0.8 | 1.2 | 1.3 | 1.5 | 1.5 |

25 | 0.6 | 0.7 | 1.0 | 1.2 | 1.2 | |

30 | 0.4 | 0.5 | 0.5 | 0.8 | ||

40 | 0.3 | 0.4 |

8kw N2 cutting | |||||

Material | Thickness | High pressure(bar) | Speed(m/min) | Low pressure(bar) | Speed(m/min) |

S.S | 4mm | 14 | 12 | 7 | 18 |

5mm | 14 | 8.5 | 6 | 13 | |

6mm | 12 | 7.5 | 6 | 10 | |

8mm | 14 | 4.5 | 5.5 | 7 | |

9mm | 13 | 4 | 5.5 | 5.5 | |

10mm | 14 | 3.4 | 7.5 | 3.9 | |

Thickness | Power | High Pressure Speed/ Pressure | Low pressure speed/ pressure | Speed Increase / Gas consumpation |

8mm | 15KW | 8.5m/min /14bar*ø3.5 | 13m/min/ 7bar*ø3.5 | 52.94%/ 50% |

10mm | 15KW | 7m/min /13bar*ø3.5 | 10m/min/ 7bar*ø3.5 | 42.86%/ 46.15% |

12mm | 15KW | 5.3m/min /11bar*ø3.5 | 7.5m/min/ 7bar*ø3.5 | 41.51%/ 36.36% |

14mm | 15KW | 3.8m/min /12bar*ø3.5 | 4.5m/min/ 8bar*ø3.5 | 18.42%/ 33.33% |

16mm | 15KW | 2.7m/min /14bar*ø3.5 | 3.0m/min/ 10bar*ø3.5 | 11.11%/ 28.57% |

SS N2 Cutting (mm/min)

8 | 15000 | 13000 | ↑ 30% |

20000 | 17000 | ||

12 | 15000 | 7000 | ↑ 42.8% |

20000 | 10000 | ||

16 | 15000 | 3000 | ↑ 100% |

20000 | 6000 | ||

30 | 15000 | 750 | ↑ 46.6% |

20000 | 1100 |

SS AIR Cutting (mm/min)

18 | 15000 | 3200 | ↑ 25% |

20000 | 4000 | ||

20 | 15000 | 2600 | ↑ 25% |

20000 | 3200 | ||

30 | 15000 | 1100 | ↑ 54.5% |

20000 | 1700 | ||

50 | 15000 | 350 | ↑ 90% |

20000 | 600 |

Thickness | 20kw(m/min) | 15kw(m/min) |

8 | 17 | 9 |

10 | 15 | 1.4 |

12 | 9 | 0.8 |

14 | 5 | 0.6 |

16 | 3.2 | |

18 | 2.5 | |

20 | 2.5 | |

30 | 0.6 |

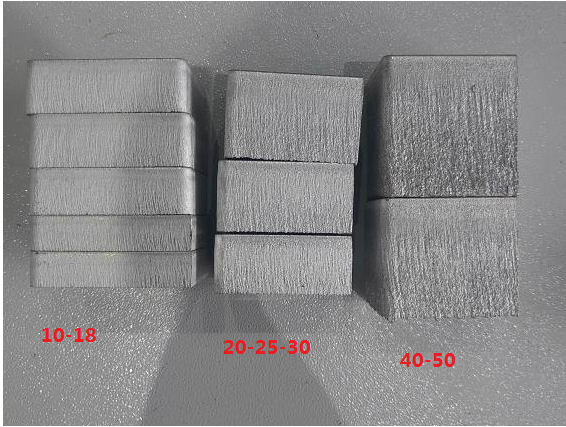

Air cutting for Aluminum plate is tremendously improved from slow speed for 14mmby 15kw, now very high speed to cut 50mm by 20kw, samples is basally without burby comparing after cutting, but efficiency is improved averagely 2-11 times faster

Mild Steel

8KW:30mm (350mm/min)

10KW:35mm (300mm/min)

12KW:40mm (220mm/min)

15KW:50mm (260mm/min)

20KW: 70mm (200mm/min)

Stainless Steel

8KW:30mm (240-260mm/min)

10KW:50mm (100-120mm/min)

12KW:50mm (130-160mm/min)

15KW:50mm (180-200mm/min)

20KW: 100mm (50mm/min)

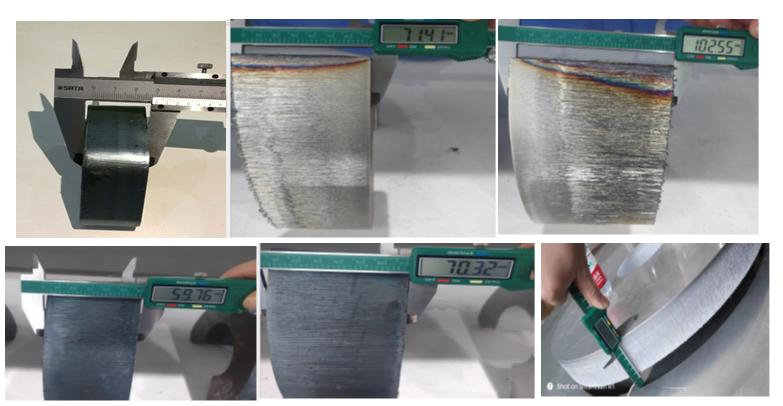

As we know that, low power is impossible to cut thick material with good edge, but if we use high power, the results are totally different, high power is not only have the capability to cut higher thickness, but also the final performance is much better than low power, it is very easy to have 30mm, 35mm,40mm Carbon Steel shining edges, which before it is even can not image.

Air Cutting performance increased.

As the above points, we already know the advantages by high power, and why we can get a faster cutting speed, if we can know the why, it is very clear to understand that by using the following picture.

Material | Thickness(mm) | 6kw | 8kw | 10kw | 12kw | 15kw |

Carbon Steel | 20 | 2S(O2) | 1.5S(O2) | 0.8S(O2) | / | 0.5S(O2) |

Carbon Steel | 25 | 2.5S(O2) | 1.8S(O2) | 1.2S(O2) | 0.8S(O2) | 0.5S(O2) |

Stainless Steel | 20 | 3S (O2) | 2S(O2) | 1S (Air) | 1S(Air) | 0.5S(N2) |

Stainless Steel | 25 | 3 (O2) | 2.2(O2) | 1.5 (Air) | 1(Air) | 0.5(Air) |

So the high high-power coil laser cutting machine is definitely a trend in future, but now in China, but not every supplier has the technical accumulations to handle the high power.

What is the main difficulties for high-power laser cutting machines?

Normally if we cut Stainless Steel, we use full power to cut the Stainless Steel, if we use full power, the inside temperature actually is huge high, once the high temperature is high, the focus will drift, if the laser head focus is not fixed, so definitely the cutting performance to the sheet is not good, we need to stop the machines until cool down.

High temperatures, also have a very big harm to the bed structure, if we use it for a longer time, definitely the bed structure will deform, the precision cannot be sure once the bed deforms.

As we know, higher power has a higher capability to high thickness, but it also takes another problem that heavy-duty sheet will have a higher requirement for the bed of the stainless steel laser cutter, the bed load need to be strong.

If all the data is higher than low power, we also need to make sure all the dynamic conditions need to be improved, we need to have a faster processing IPC and also a faster AC speed etc..

So to solve the above questions, please message us with thanks.

Remcor, the professional laser machine supplier, has 18 years experience in machine designing and manufacturing, and has 5000 sets of installations globally to offer OEM/ODM services for our customers, if need more details, please help to message us.

Thanks for your time watching