Nov 15 , 2025

Laser cleaning has rapidly become one of the most efficient, eco-friendly, and precision-based surface-treatment technologies available today. As industries shift away from chemical cleaning and abrasive blasting, laser rust removal continues to grow in popularity due to its speed, safety, and long-term cost benefits.

At Remcor Technology, we specialize in advanced laser cleaning solutions designed for rust removal, oxide treatment, paint stripping, and precision surface restoration.

This article explains in detail how laser cleaning machines work, especially for rust removal, based on key technical principles and industrial practices.

Laser cleaning is based on the scientific process known as laser ablation.

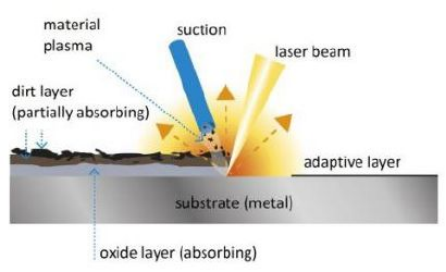

A high-energy laser beam is directed onto a contaminated surface. Rust, oxide, or paint absorbs the laser energy far more efficiently than the underlying metal. This difference in absorption produces:

·

Rapid micro-evaporation of the rust layer

· ·

Thermal expansion and shockwaves that lift contaminants away

· ·

Non-contact cleaning that leaves the base material intact

·

Key characteristics of laser ablation:

Selective removal of rust without damaging steel, aluminum, brass, copper, or other substrates

Zero use of chemicals or abrasive media

High precision even on complex surfaces

Minimal heat impact due to ultra-short pulse durations

This makes laser ablation ideal for industries aiming for high-quality, damage-free rust removal.

Laser cleaning systems use different laser sources depending on application requirements. The most common types include:

Normally Pulse type no have any harm to the base material with minimal hurt to the base material, normally the pulse laser source maximum power is up to 2kW, but for the fiber laser laser source CW type, the maximum power is up to 6000W, by higher power, the cleaning efficiency is much faster to the rust cleaning

·

Excellent beam quality·

High energy efficiency·

Long service life (50,000+ hours)··

Ideal for metal rust removal and oxide cleaning

·

·

Nanosecond or picosecond pulse width

Creates powerful energy bursts that remove contamination instantly

Minimizes heat input to the base material

Best for delicate surfaces, mold cleaning, and historical restoration

Feature | CW Laser | Pulsed Laser |

Beam Output | Continuous, steady beam | Short bursts of high-energy pulses |

Heat Impact | High | Very low |

Peak Power | Lower | Extremely high |

Surface Safety | May cause melting or burns | Safe on delicate materials |

Precision Level | Medium | Very high |

Best For | Cutting, welding, heavy cleaning | Rust removal, paint stripping, fine cleaning |

Cleaning Quality | Rough, more thermal effect | Clean, controlled ablation |

Remcor Technology primarily uses pulsed fiber lasers, offering the strongest performance for rust removal with minimal risk of material damage.

Here is a clear breakdown of how a laser cleaning machine works during a rust removal operation:

Connect power, cooling system, and cleaning head

Set appropriate parameters based on rust thickness and material type

The laser beam exits the cleaning gun through a focusing lens

Beam diameter and pulse frequency are adjusted for optimal cleaning

Rust absorbs laser energy instantly

The base metal reflects most of the energy, preventing damage

Rapid micro-explosions lift rust away

Dust and particles are vaporized or collected using dust extraction systems

No abrasion

No chemical residue

No secondary waste

This step-by-step process provides a controlled, safe, and highly efficient cleaning workflow used across industries.

Laser cleaning is safe when proper protection measures are followed.

Remcor Technology machines are designed with strict safety standards:

·

Laser safety goggles appropriate for the laser wavelength

Enclosed or shielded cleaning areas to prevent accidental exposure·

Proper ventilation or dust extraction· ·

Training on safe operating procedures·

Emergency stop systems and interlocks

·

Laser systems are classified under international safety standards (e.g., Class IV), meaning safety controls are essential during operation.

Laser cleaning is widely used for both industrial and commercial applications. Some of the most common include:

Ideal for steel structures, automotive parts, and metal fabrication.

Removes welding oxides, anodizing layers, and corrosion products.

A precise alternative to sandblasting and chemical stripping.

Used in tire molds, plastic injection molds, and rubber tooling.

For welding, bonding, polishing, or coating applications.

Removes stains, oxidation, and contaminants from stone, metal, and wood.

Industries using laser cleaning include automotive manufacturing, aerospace, shipbuilding, rail transit, electronics, and many more.

Pulsed laser cleaning is compatible with a wide range of materials due to its low heat input and non-destructive nature.

·

Carbon steel· ·

Stainless steel·

Aluminum alloys·

Copper & brass·

Titanium·

Cast iron· ·

Stone surfaces· ·

Wood (for controlled, low-power cleaning)· ·

Ceramic & composite materials· ·

Precision molds (steel, chrome-plated, or nickel-plated)

·

·

Rust, corrosion, and oxide layers·

Paint, powder coatings, grease· ·

Oil stains and industrial residues· ·

Soot and carbon buildup· ·

Welding discoloration and oxidation· ·

Rubber residue on molds

·

Pulsed lasers provide the perfect combination of high cleaning power with low thermal impact, making them ideal for delicate or high-value components.

Remcor Technology offers advanced, industry-grade laser cleaning machines with:

·

High-efficiency pulsed fiber lasers·

User-friendly interfaces··

Stable long-term performance· ·

Professional technical support·

Custom solutions for manufacturing, automotive, aerospace, and restoration industries

·

Our systems are engineered to deliver faster cleaning, lower operating cost, and zero surface damage, helping businesses improve efficiency and reduce maintenance costs.