Laser cleaning is an advanced surface treatment technology based on the precise interaction between laser energy and material surfaces. By utilizing controlled laser irradiation, contaminants and unwanted surface layers can be efficiently removed without affecting the base material. Compared with traditional cleaning methods, laser cleaning offers significant advantages including non-contact processing, zero substrate damage, high cleaning accuracy, green environmental protection, and easy integration into automated production lines. It is especially suitable for high-speed, on-line cleaning applications in designated areas.

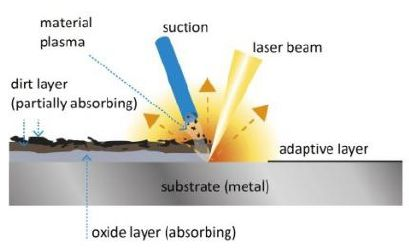

Figure 2.1 – Laser Cleaning Schematic Diagram

The Pulse Type Laser Cleaning Machine manufactured by our company represents a new generation of high-tech surface treatment equipment. Designed for industrial reliability and ease of use, this laser cleaning machine features simple installation, intuitive control, and strong automation capability. The system can be put into operation by simply connecting the power supply and starting the equipment.

This pulse type laser cleaning machine operates without chemical reagents, abrasive media, water, or secondary consumables. During the cleaning process, there is no dust, no wastewater, and no secondary pollution, fully meeting modern environmental protection and occupational safety requirements.

With its high peak pulse energy and precise energy control, the pulse type laser cleaning machine delivers excellent cleaning selectivity and surface cleanliness. It can effectively remove resin, paint, oil stains, grease, dirt, rust, coatings, plating layers, and oxide layers from various material surfaces, while preserving the integrity of the substrate.

The Pulse Type Laser Cleaning Machine provides a reliable, efficient, and environmentally friendly alternative to conventional cleaning technologies, making it an ideal solution for modern industrial surface treatment applications.

The portable laser cleaning machine is available in both air cooling and water cooling configurations to suit different power levels and working conditions.

Cooling method: Forced air cooling

Power range: 100W – 500W

Compact and lightweight

Easy to transport and operate

Best for intermittent or light-duty cleaning

Typical applications:

Light rust removal, oil and grease cleaning, on-site maintenance, mobile service operations.

Cooling method: Industrial water chiller

Power range: 500W – 2000W

Stable thermal control for long-duty cycles

Higher continuous working capability

Suitable for heavy-duty industrial cleaning

Typical applications:

Heavy rust removal, thick coating stripping, large-area surface preparation, production-line operations.

Short laser output duration

Extremely high peak power

Precise energy control

Minimal heat-affected zone (HAZ)

Continuous Wave (CW) laser output

Constant and stable energy delivery

High average power

Faster cleaning speed for large surfaces

Both laser types are available in the portable laser cleaning machine, allowing users to select the best solution based on precision or productivity requirements.

Air Cooling Laser Cleaning Machine:

100W – 500W, optimized for portability and ease of use

Water Cooling Laser Cleaning Machine:

500W – 2000W, designed for high efficiency and continuous industrial operation

This wide power range ensures that the laser cleaning machine can handle applications from delicate precision cleaning to heavy industrial surface treatment.

To meet different usage scenarios, the portable laser cleaning machine is available in three main design types:

| Type | Cooling Method | Power Capability | Mobility | Best Application |

|---|---|---|---|---|

| Bag-pack battery type | Air cooling | Low–medium power | Ultra-portable | High altitude & outdoor work |

| Drawer type | Air cooling | Medium power | Wheeled & mobile | City & on-site services |

| Water cooling cabinet type | Water cooling | High power | Fixed / semi-mobile | Industrial & heavy-duty cleaning |

Professional comparision, the website link can be helpful to understand all the differences, you can click the link below

Ultra-high cleaning precision

Almost zero damage to base material

Excellent control for thin layers and delicate surfaces

Minimal thermal stress and deformation

Ideal for high-value and sensitive components

Aerospace and aviation components

Electronics and semiconductor industries

Precision molds and tools

Medical devices

Pre-bonding and pre-coating surface preparation

The pulse type laser cleaning machine is the preferred choice where surface integrity and precision are critical.

Choose a multimode laser cleaning machine if your application requires:

Smooth and uniform cleaning

Minimal surface damage

Bright and consistent surface finish

The even energy distribution of multimode lasers ensures gentle and controlled material removal.

A single-mode laser cleaning machine is recommended when:

Cleaning high-reflectivity materials such as aluminum or copper

A slightly roughened surface is required after cleaning

Stronger laser-material interaction is needed

Single-mode lasers provide better stability when working with reflective metals.

If the customer is not certain about the specific cleaning scenario, selecting either:

A single-mode laser cleaning machine, or

A multimode laser with 5 mJ single-pulse energy

is a safe and versatile solution that covers most laser cleaning applications.

For applications such as:

Thin paint removal

Engine carbon deposit cleaning

Mold and tooling cleaning

It is recommended to choose, within the same power class, the laser cleaning machine with the highest single-pulse energy, ensuring higher efficiency and faster cleaning speed.

For:

Rust removal

Aluminum and copper cleaning

Applications requiring controlled surface roughness

A single-mode pulse laser cleaning machine, typically with 1.5–2 mJ single-pulse energy, is the optimal choice.

Do not hesitate to give us a call or drop off a message if you have any question.