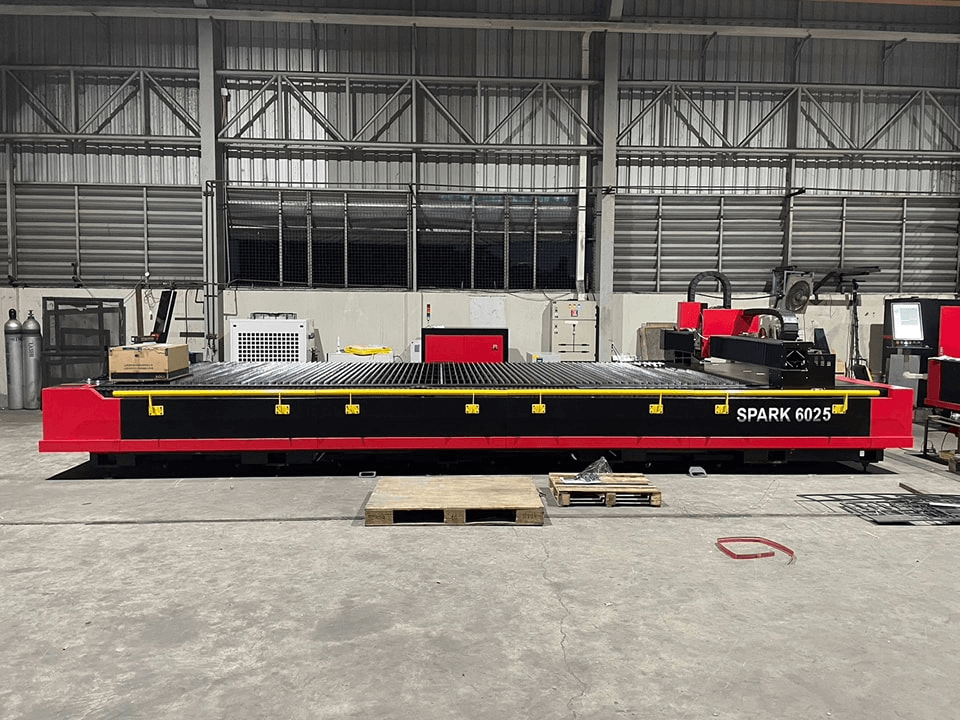

If you are looking for a high cost-effective fiber laser cutting machine that balances machine quality, cutting performance, and investment cost, the Spark N fiber laser cutting machine is your ideal choice. Designed for customers who demand higher productivity, faster cutting speed, and long-term structural stability, Spark N is widely recognized as a reliable industrial CNC fiber laser cutting machine.

As a professional laser cutting machine manufacturer in China, Remcor Technology developed the Spark N series specifically for customers who already own entry-level machines or are planning to upgrade to higher laser power fiber laser cutting machines for medium to high-volume sheet metal processing.

Below are the core advantages of the Spark N series, listed clearly and professionally for easy comparison and selection.

For most customers, a 6000W fiber laser cutting machine is the optimal configuration. It offers an excellent balance between:

High cutting speed

Wide processing thickness range

Energy efficiency

Strong return on investment

The Spark N CNC fiber laser cutting machine with 6000W laser power is ideal for medium and large sheet metal fabrication factories. Compared with entry-level models, it delivers significantly higher efficiency, faster throughput, and better production capacity.

The Spark N series features an independent electric cabinet, which separates electrical components from the main machine body.

Advantages include:

Larger internal space for easier maintenance

Better ventilation and heat dissipation

Higher electrical safety standards

The laser source and air conditioner can also be installed inside the independent cabinet, creating a more stable cooling environment. This design significantly improves long-term reliability, especially for high-power fiber laser cutting machines.

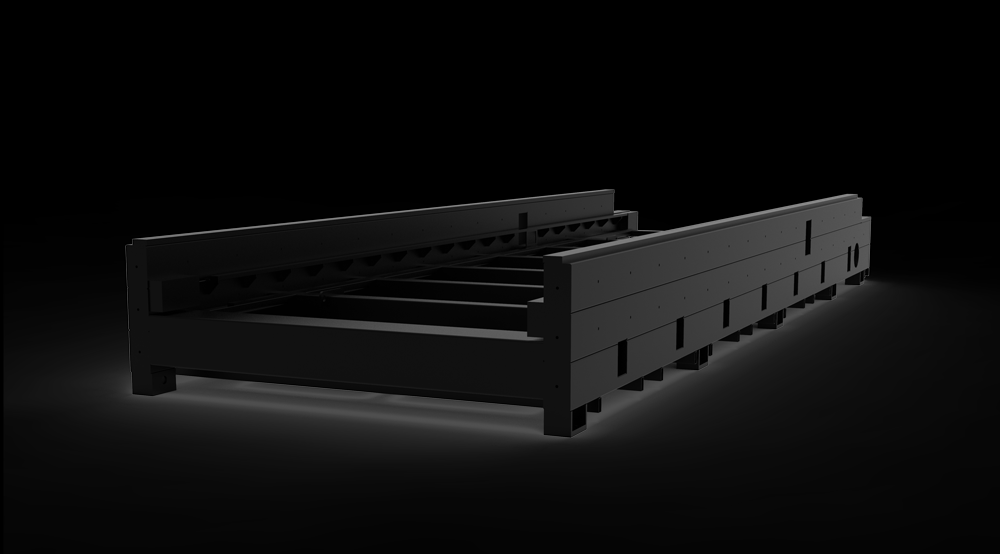

The machine body is the most critical part of any industrial fiber laser cutting machine.

The Spark N series adopts a pipe + plate welding structure, designed for long-term industrial use with a 10-year structural lifespan. Taking the Spark N 3015 fiber laser cutting machine as an example, the total body weight reaches up to 3 tons, far heavier than standard market models.

The benefits of a heavier body include:

Excellent vibration resistance

No shaking during high-speed cutting

Higher cutting precision and consistency

Improved long-term accuracy

This makes the Spark N an ideal high-precision CNC fiber laser cutting machine for demanding production environments.

At Remcor Technology, we believe small details determine real quality. The Spark N fiber laser cutting machine includes multiple refined design features:

Clearly marked electrical wiring, mostly in English, making installation, maintenance, and troubleshooting easier

Electrical wires arranged neatly and color-coded according to international safety standards

Ball supports on the front, left, and right sides for smooth sheet loading

Sheet metal dust-proof cover near the laser cutting head to prevent sparks and debris

Automatic lubrication system to ensure smooth movement and reduce mechanical wear

These details greatly improve safety, usability, and machine lifespan.

Unlike economical models, the Spark N fiber laser cutting machine mainly uses international and top-tier brands for critical components:

Servo motors and drivers: FUJI&Yaskawa

Electrical components: Schneider and Siemens

Industrial chiller: Tongfei (top-quality brand in China, widely recognized for stability and cooling performance)

This high-end configuration ensures superior performance, long service life, and consistent cutting quality for industrial applications.

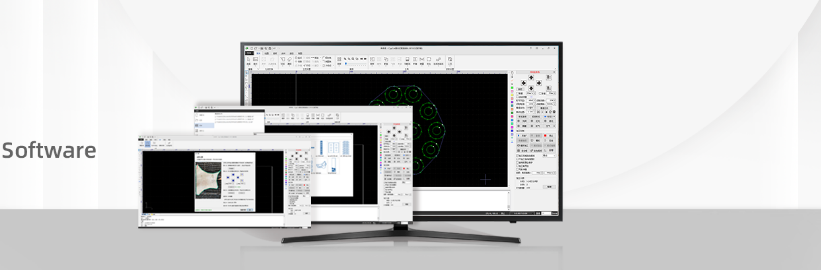

The Spark N CNC fiber laser cutting machine is equipped with the BOCHU CNC controlling system, the most widely used and market-proven system in the laser cutting industry.

Combined with the BLT laser cutting head, this configuration provides:

Excellent cutting head stability

Superior performance for thick metal cutting

High precision and smooth cutting edges

When cutting higher thickness materials, the stability advantages of this system become especially clear.

Every Spark N fiber laser cutting machine is fully tested and debugged before delivery, including cutting tests and idle running.

After arrival, customers only need to connect:

Power supply

Water supply

Auxiliary systems

All cutting parameters are pre-configured, allowing customers to start production within one day of installation, without complicated commissioning.

All Remcor fiber laser cutting machines come with:

24-month warranty

Lifetime technical service support

24/7 online technical assistance

Once you choose Remcor Technology, you receive professional support throughout the entire lifecycle of your CNC fiber laser cutting machine.

Spark E (Eco Type):

An entry-level fiber laser cutting machine, suitable for first-time users, trial production, and thin metal cutting. Thin sheets account for nearly 80% of cutting applications, making Spark E a cost-effective starting solution.

Spark N (Normal Type):

Designed for customers who need higher laser power, faster cutting speed, and greater efficiency. With a heavier body and stronger structure, Spark N is ideal for industrial-level production.

Remcor Technology supports full customization and OEM services, including:

Machine color and appearance

Logo branding

Structural and technical customization

We welcome customized projects under confidentiality agreements, providing exclusive solutions for distributors and brand partners.

If you are searching for a 6000W fiber laser cutting machine, a high-precision CNC fiber laser cutting machine, or a trustworthy laser cutting machine manufacturer in China, the Spark N series from Remcor Technology is a proven and reliable choice.

| Spark E | Spark N | Spark H | |

| System | Raytools system, Weihong System, Au3tech System | Bochu System | Bochu System |

| Servo motor | Innovance motor & Bochu Motor (≥ 0.85KW) | Yaskawa Motor ≥1.3KW | Yaskawa Motor ≥1.3KW |

| Electric cabinet | Integrated cabinet | Independent cabinet | Independent cabinet |

| Weight (3015) | 2000KGS | 3000KGS | 3500KGS |

| SMC proportional valves | O2 Valves | O2 and N2 valves | O2 and N2 valves |

| Electric parts | CHINT | Schneider | Schneider |

| Maximum Power (Laser Source) | ≤3000W | ≤12000W | ≥6000W |

| Body Structure | Pipe welding | Pipe&Plate welding | Plate welding |

The bed body adapts the segmented rectangular tube welding bed with fully annealed treatment at over 600⁰. After tempering, the strength, rigidity and stability are guaranteed

the precision would be tested and debugged which can make sure the precision can be maintained for a long time.

Standard auto focus function, no need focus adjustment while changing sheet; Automatic tracking and accurately adjusting the focus according to the material thickness

to ensure the best cutting effect of the whole board. Shorter perforation time, better perforation quality, high-speed cutting, saving time.

Mostly the CNC controlling system is from Bochu, which is the most common controlling system in China, which is the most stable and competitive brands

Also with their cutting head combination, now is the first choice for the customers

Thanks to the Bochu CNC system, it have a lot of different versions from low power to high power

It definitely have a higher requirement for the laser cutting head also along with the controlling system

For our Spark N fiber laser cutting machine, it mainly use the combinations as below

1) 2000+BLT 310 for the laser source power 3000W

2) 4000+BLT 421 for the laser source power 6000W

3) 6000+BLT 441 & 8000+BLT 642 for the laser source power 12000W

From our year experiences, if the machine runs with a good condition, the water chiller is really very important

It is used for the laser source cooling, the laser cutting head cooling, once both parts is not full cooled, the machine will have the alarms

For a better cooling performance, we recommend to use the Brand Tongfei, it is slightly higher cost than the brands of Hanli & S&A

But for a longer life time for the laser cutting head and laser source, it is worthy to have a try

![]()

Do not hesitate to give us a call or drop off a message if you have any question.