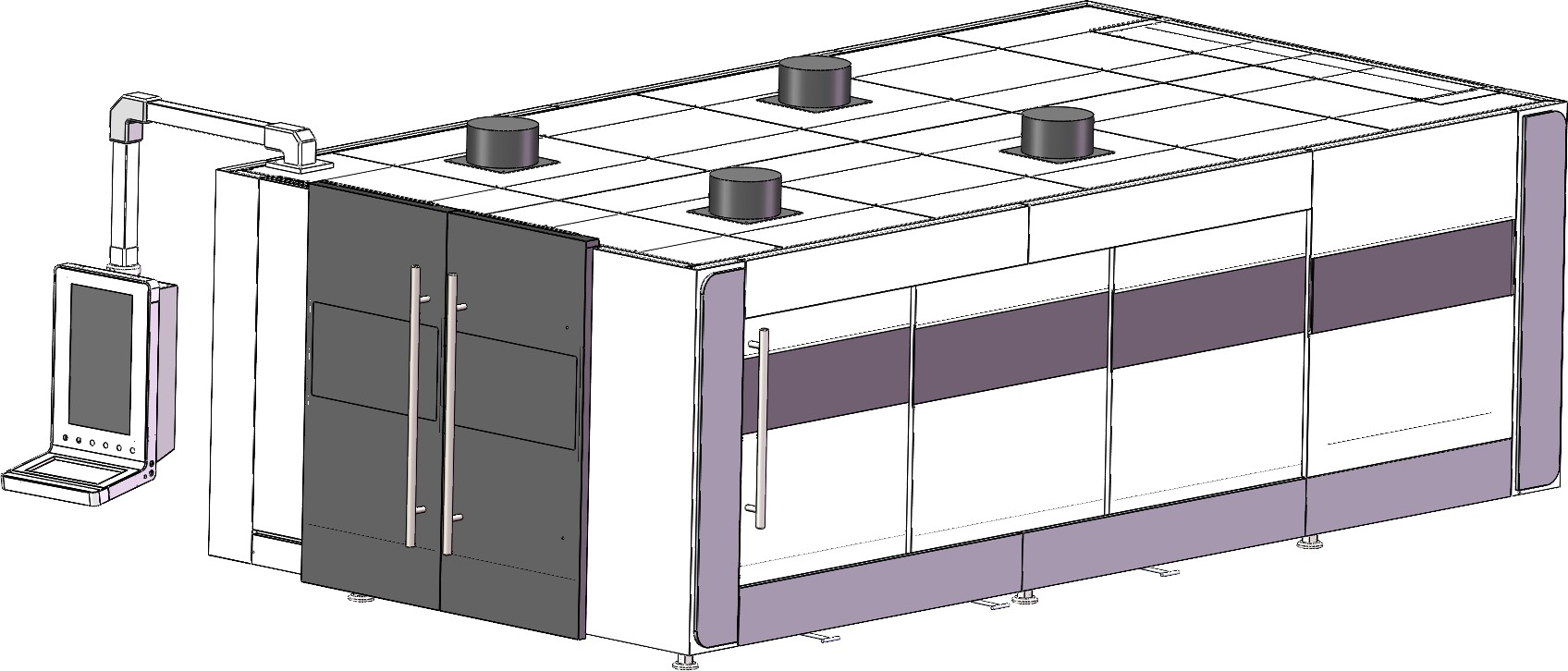

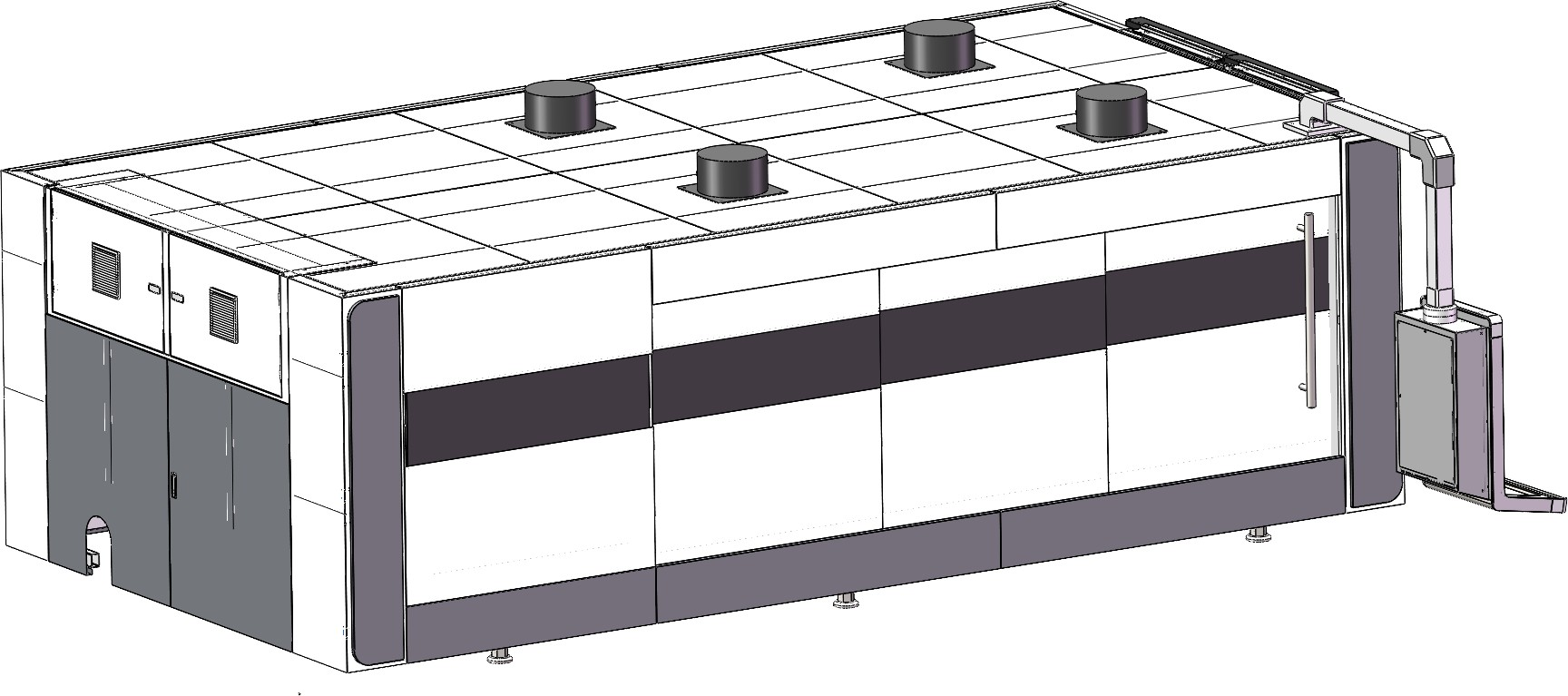

The PLUTO 3015 Single Table Enclosed Fiber Laser Cutting Machine is a compact, high-safety solution designed for customers who require CE-compliant fiber laser cutting machines but operate in limited factory space.

For workshops that mainly process small to medium-sized sheet metal parts, this single table full cover fiber laser cutter provides an excellent balance between safety, productivity, and space efficiency.

With a 3015 working size (3000 × 1500 mm), fully enclosed structure, and optimized smoke extraction system, PLUTO 3015 is widely used in Europe and other regulated markets.

Fully enclosed cover on top, left, and right sides

Effectively blocks laser radiation, sparks, and debris

Designed to meet European CE safety standards

Ensures maximum operator protection

This makes PLUTO 3015 a reliable single table enclosed cover fiber laser cutting machine for international users.

Working area: 3000 × 1500 mm

Optimized for small and medium sheet metal cutting

Ideal for factories with limited floor space

Reduces overall installation footprint while maintaining productivity

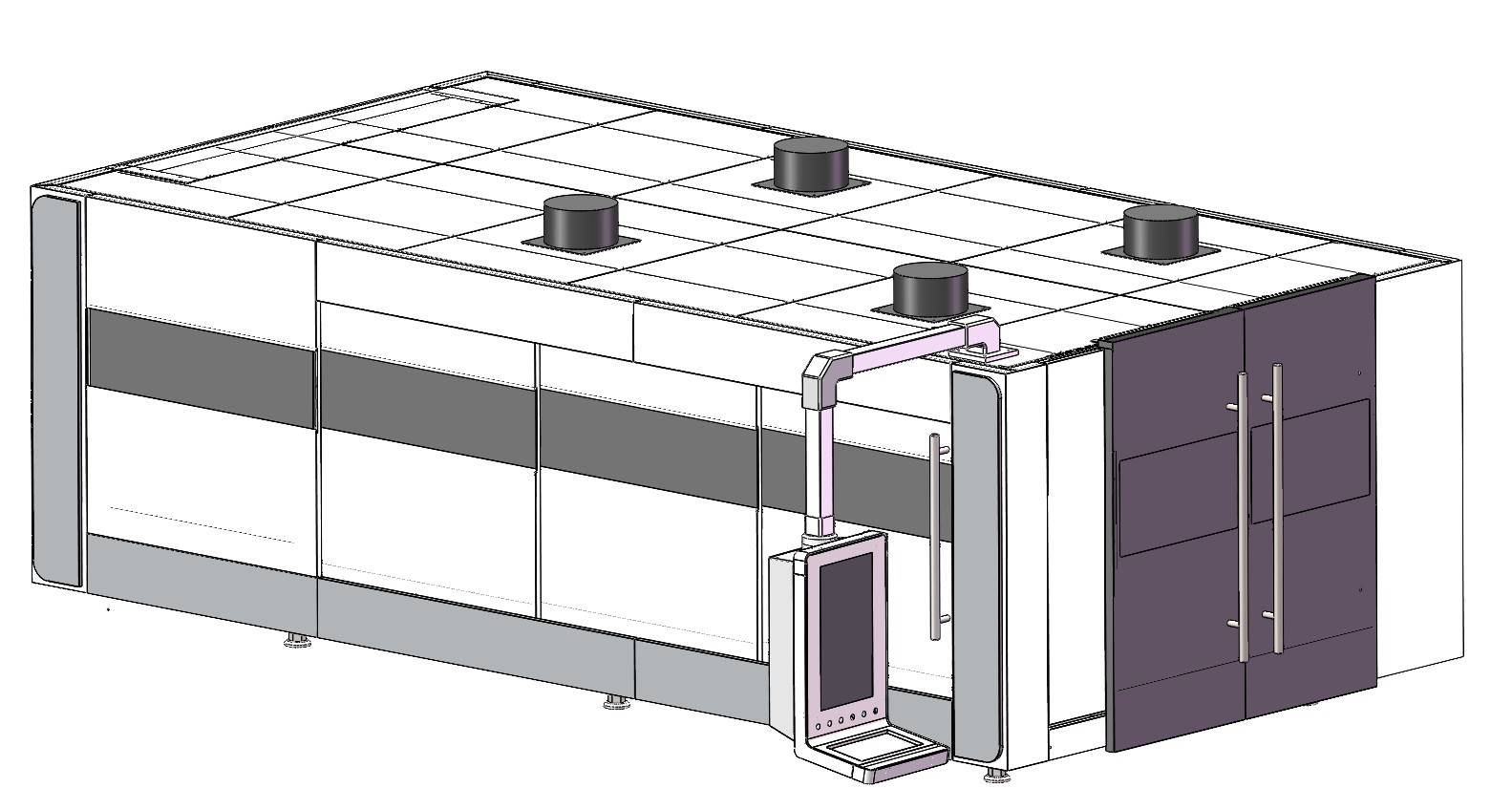

Electrical cabinet is positioned at the rear of the machine

Improves space utilization and cable management

Enhances machine stability and electrical safety

Easy access for maintenance and inspection

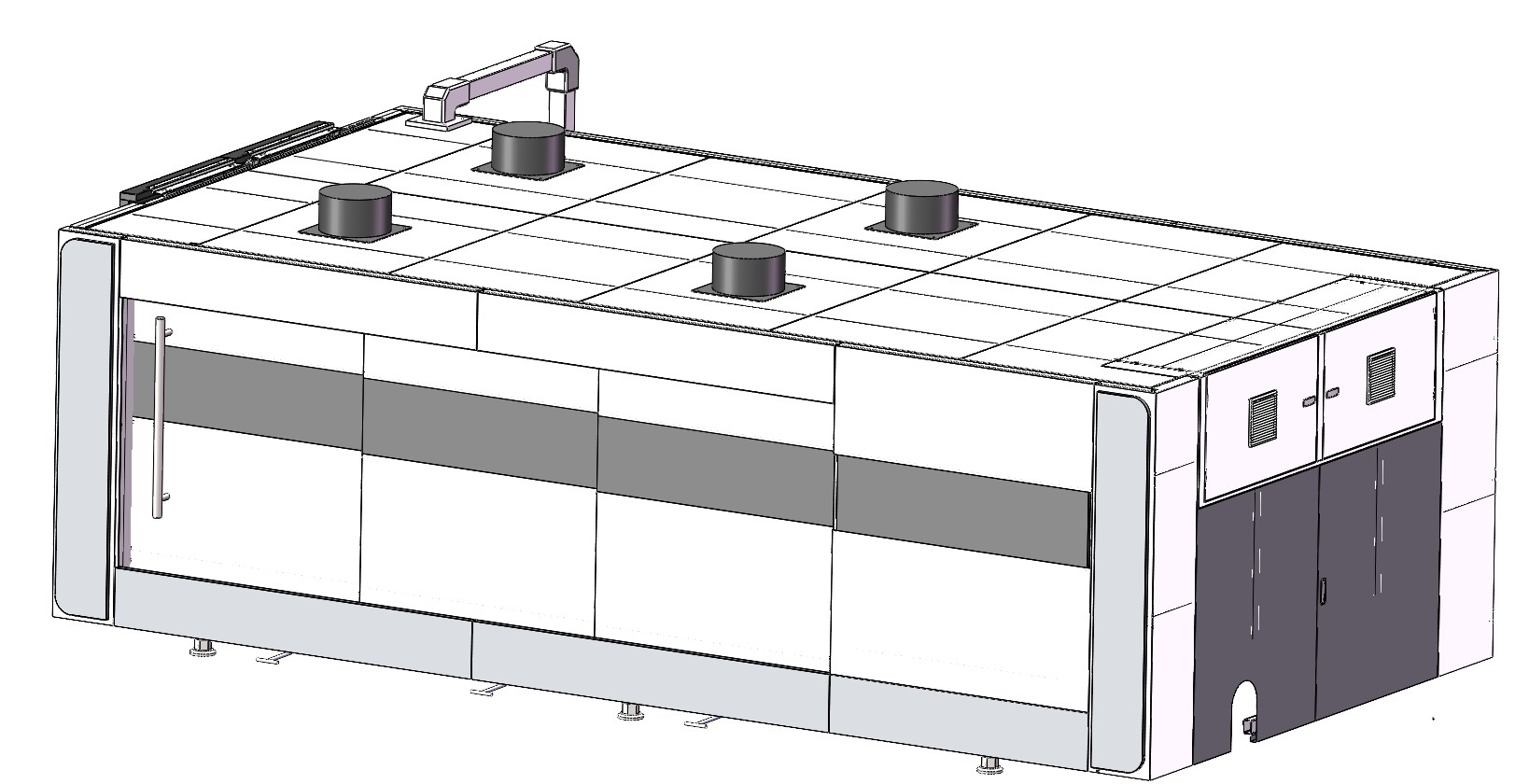

Left and right side doors are movable

Materials can be loaded from the front, left, or right side

Suitable for different workshop layouts

Improves loading efficiency and production flow

Standard top-mounted exhaust fans

Quickly evacuates smoke, fumes, and metal dust

Improves air quality inside the enclosure

Essential for clean and safe laser cutting operations

Front door opening distance: up to 1600 mm

Left side door opening distance: up to 3100 mm

Allows easy loading of metal sheets

Convenient for machine maintenance and daily operation

.jpg)

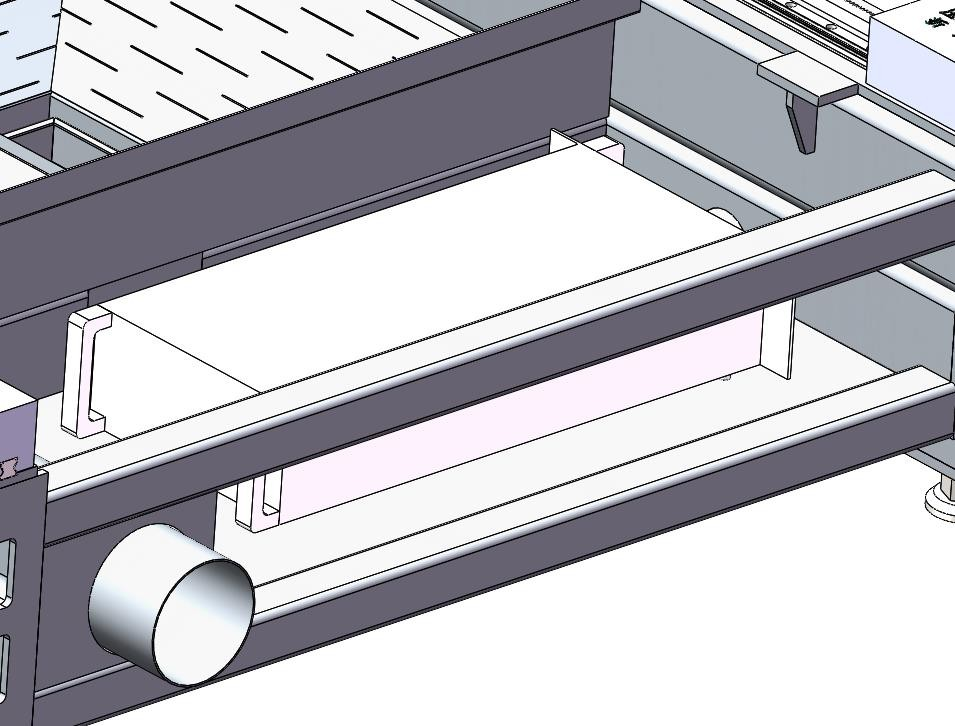

Equipped with sectional dust extraction zones

Smoke is extracted directly from the cutting area

Improves fume removal efficiency

Reduces dust accumulation inside the enclosure

Ergonomic rotatable control panel

Adjustable viewing angle for operators

Improves operational comfort and safety

Enhances user experience during long working hours

Built-in internal camera for real-time monitoring

Operators can observe the cutting process safely

No need to open the enclosure during operation

Improves cutting accuracy and operational control

Special compartment at the rear side for the laser source

Ensures proper ventilation and protection

Easy access for laser source maintenance or upgrades

Improves long-term machine reliability

Sheet metal fabrication

Small and medium laser cutting workshops

CE-required production environments

Users searching for a single table full cover fiber laser cutter

Factories with limited workshop space

The PLUTO 3015 Single Table Enclosed Fiber Laser Cutting Machine is a cost-effective, safe, and compact solution for modern sheet metal processing. Its full enclosure, CE compliance, and flexible operation design make it an excellent choice for customers who demand safety, efficiency, and space optimization.

Do not hesitate to give us a call or drop off a message if you have any question.