The handheld laser cleaning machine with a CW (Continuous Wave) laser source and industrial water chiller is an advanced surface treatment solution designed for modern manufacturing environments in Europe and North America. It delivers high cleaning efficiency, consistent performance, and long-term cost savings while fully supporting environmental regulations, workplace safety standards, and Industry 4.0 requirements.

The laser cleaning machine removes surface contaminants by directing a controlled laser beam onto the target area. The laser energy is absorbed by rust, oxides, oil, grease, paint, or coatings, causing rapid thermal expansion and vaporization. The base material—steel, aluminum, stainless steel, or other metals—remains unaffected due to its different absorption characteristics.

Key technical characteristics:

Non-contact process – no mechanical stress

No consumables – no chemicals or abrasives

Highly controllable energy output for consistent results

The CW laser cleaning machine provides stable and continuous laser power, making it particularly suitable for large-area cleaning, heavy rust removal, and pre-welding surface preparation in industrial production lines.

Compared with chemical cleaning, sandblasting, wire brushing, or solvent-based processes, the laser cleaning machine offers clear advantages valued by European and North American manufacturers.

No chemicals, solvents, or hazardous waste

Supports EU environmental directives, OSHA, and EPA requirements

Cleaner and safer working environment

No surface damage or material loss

No micro-cracks or deformation

Ideal for precision parts and high-value components

Eliminates ongoing consumable costs

Minimal maintenance requirements

Long service life of fiber laser source

Faster cleaning speed than manual or chemical methods

Continuous operation suitable for production environments

Reduced downtime and labor dependency

Easy integration with robotic arms and CNC systems

Supports automated and semi-automated production lines

Ideal for smart factories and lean manufacturing

Rust and oxide removal

Paint and coating stripping

Pre-welding and pre-coating surface treatment

Mold cleaning, maintenance, and refurbishment

Selecting the right laser cleaning machine is critical for achieving optimal cleaning efficiency, process stability, and long-term return on investment. The following comparison outlines the key differences between air cooling laser cleaning machines and water cooling laser cleaning machines, as well as CW laser cleaning machines and pulse cleaning machines, to support informed purchasing decisions.

Air Cooling Laser Cleaning Machine

Heat dissipation through forced air cooling

No external water chiller required

Simplified internal structure

Water Cooling Laser Cleaning Machine

Uses an industrial water chiller for thermal management

Maintains stable laser temperature during continuous operation

Designed for higher power output and long-duty cycles

Air Cooling Laser Cleaning Machine

Typically low to medium power

Limited continuous operation time under heavy load

Best for intermittent or light-duty cleaning tasks

Water Cooling Laser Cleaning Machine

Supports medium to high laser power

Stable performance for long, continuous industrial operation

Ideal for production-line and heavy-duty applications

Air Cooling Laser Cleaning Machine

Compact and lightweight

Easy to transport and operate on-site

Suitable for mobile and outdoor applications

Water Cooling Laser Cleaning Machine

Larger footprint due to water chiller

More suitable for fixed industrial installations

Higher system stability and durability

Air Cooling Laser Cleaning Machine

Light rust and oxide removal

Oil, grease, and surface contaminants

Maintenance and repair operations

Water Cooling Laser Cleaning Machine

Heavy rust removal and thick coatings

Large-area surface cleaning

Pre-welding and pre-coating industrial preparation

CW Laser Cleaning Machine

Continuous Wave (CW) laser output

Constant and stable energy delivery

High average power for fast material removal

Pulse Cleaning Machine

Pulsed laser output with ultra-high peak power

Laser energy released in short pulses

Precise and controllable cleaning process

Not harmful to base material

CW Laser Cleaning Machine

Very high cleaning speed

Suitable for large surfaces and thick contaminants

Optimized for productivity-driven applications

Pulse Cleaning Machine

Slower cleaning speed compared with CW

Extremely high cleaning precision

Best for thin layers and sensitive surfaces

CW Laser Cleaning Machine

Higher heat input due to continuous energy

Requires proper parameter control to avoid heat accumulation

Ideal for robust metal substrates

Pulse Cleaning Machine

Minimal heat-affected zone (HAZ)

Almost no thermal damage to base material

Preferred for precision and high-value components

CW Laser Cleaning Machine

Structural steel and heavy equipment

Shipbuilding and construction machinery

Automotive frames and large metal parts

Pulse Cleaning Machine

Aerospace and aviation components

Electronics and precision molds

Medical devices and high-end manufacturing

Both air cooling laser cleaning machines and water cooling laser cleaning machines offer unique advantages depending on operational requirements. Similarly, the choice between a CW laser cleaning machine and a pulse cleaning machine depends on the balance between cleaning speed, precision, and thermal sensitivity.

By selecting the appropriate laser cleaning machine, manufacturers can significantly improve cleaning quality, reduce operating costs, and comply with modern industrial and environmental standards.

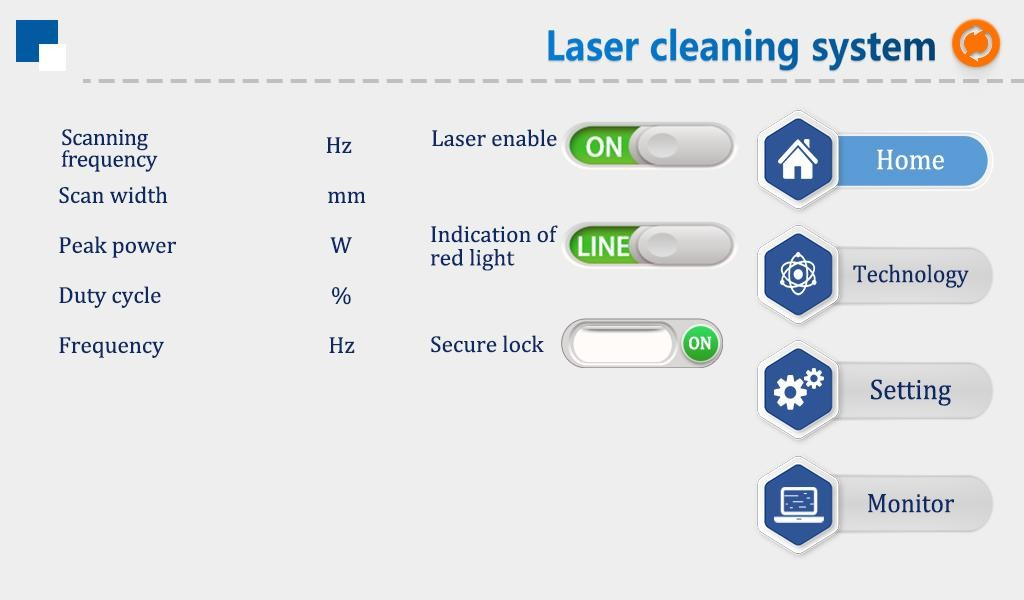

Laser Cleaning controlling system, currently the main in the market is SUP laser cleaning system with professional cleaning gun, which customization is available

The Laser source mainly in the market is Raycus & Max photonics, and other brands are also available such as RECI, Everfone, BWT etc.

Currently the Maximum laser source for the water cooling type is 6000W

Answer: As it is the water cooling laser cleaning machine, once we use a higher volume of the chiller for the enough cooling, now the tested maximum power is 6000W

Answer: The cleaning width is effected by the focus diameters, once the focus diameter is bigger, the cleaning width is bigger, currently the cleaning width is 500mm

Answer: CW is continuous Wave, high powre output, is harmful to base material, but pulse laser source is different, is high peak but short time output, which no harmful to the base material, so the final application is different, Pulse laser source is mainly for the precise cleaning, also for the wood,paper etc.

Answer: Yes, it is possible, thanks to the supply chains, we can offer the customization from the water cooling cabinet, machine color, controlling system, cleaning gun, laser source etc. with a good relationship with the suppliers, we can offer a good quality with attractive prices, we also welcome to your inquiries

Do not hesitate to give us a call or drop off a message if you have any question.