If you are looking for higher cleaning efficiency for demanding surface treatment tasks that require higher laser power, effective heat dissipation, and zero damage to the base material, the water cooling pulse laser cleaning machine is the ideal solution.

Compared with air-cooled laser cleaning systems, a water cooling pulse laser cleaning machine offers superior thermal management, higher output stability, and stronger cleaning capability, making it the preferred choice for industrial-grade laser cleaning applications.

The integrated water cooling system efficiently controls heat distribution during high-power laser operation. This allows the water cooling pulse laser cleaning machine to work stably at higher power levels, typically ranging from 500W to 2000W.

Key benefits include:

Efficient heat dissipation during continuous operation

Stable laser output at high power

Longer continuous working time

Improved system reliability for industrial use

Thanks to this advanced cooling design, the water cooling laser cleaning machine is ideal for large-scale, high-intensity, and long-duration cleaning jobs.

As laser power increases, the maximum single-pulse energy also rises significantly. A high-power water cooling pulse laser cleaning machine delivers stronger laser impact per pulse, resulting in:

Much higher cleaning efficiency

Faster removal of heavy rust and thick coatings

Improved performance on stubborn contaminants

Reduced processing time per workpiece

This makes the handheld pulse laser cleaning machine with water cooling especially effective for heavy-duty industrial applications such as thick oxide layers, old paint removal, and severe corrosion treatment.

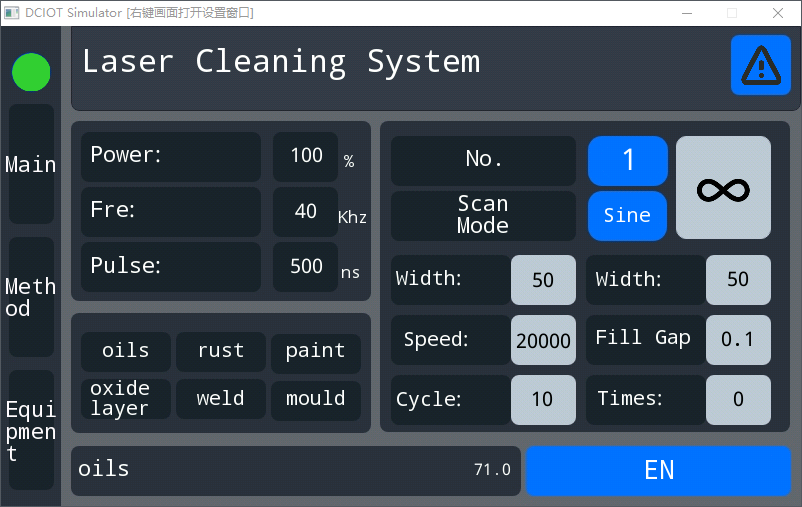

Most water cooling pulse laser cleaning machines are equipped with multimode laser sources, which provide multiple configuration options for different industries and materials.

Advantages of multimode laser structure include:

Different single-pulse energy options

Flexible power configurations

Better adaptability to various cleaning tasks

Optimized performance on complex surfaces

Customers can select the most suitable handheld water cooling pulse laser cleaning machine based on specific cleaning requirements, improving overall cost-effectiveness.

One major advantage of the water cooling pulse laser cleaning machine is its excellent laser output stability. The water cooling system maintains a consistent working temperature, ensuring:

Uniform energy output

Controlled thermal influence

No deformation or micro-damage to the base material

This makes the handheld pulse laser cleaning machine suitable for precision cleaning applications where surface integrity is critical, such as mold cleaning, heritage restoration, and precision metal treatment.

By effectively reducing thermal stress, the water cooling pulse laser cleaning machine significantly extends the service life of key components, including:

Laser source

Optical components

Internal electronic modules

Compared with air-cooled systems, a water cooling laser cleaning machine offers lower failure rates, reduced maintenance costs, and higher long-term reliability for industrial customers.

Despite its high power, the water cooling pulse laser cleaning machine still supports a handheld pulse laser cleaning head, allowing flexible operation.

Advantages include:

Comfortable grip design

High maneuverability for complex surfaces

Suitable for manual, semi-automatic, or integrated systems

This combination of high power + handheld flexibility makes the handheld water cooling pulse laser cleaning machine ideal for workshops, factories, and on-site industrial cleaning

The water cooling pulse laser cleaning machine uses advanced laser technology that is:

Chemical-free

Water-free in the cleaning process itself

Non-contact

Non-abrasive

It efficiently removes rust, paint, oxide layers, oil, grease, and industrial contaminants without secondary pollution, supporting green manufacturing and sustainable industrial production.

The water cooling pulse laser cleaning machine is the optimal choice for customers who require high power, high efficiency, long working time, and industrial-grade stability. With superior heat dissipation, higher single-pulse energy, multimode laser configuration, and handheld flexibility, it outperforms traditional air-cooled laser cleaners in demanding applications.

Whether used as a handheld pulse laser cleaning machine or integrated into automated systems, the water cooling laser cleaning machine delivers reliable, precise, and efficient cleaning for modern industrial needs.

Do not hesitate to give us a call or drop off a message if you have any question.