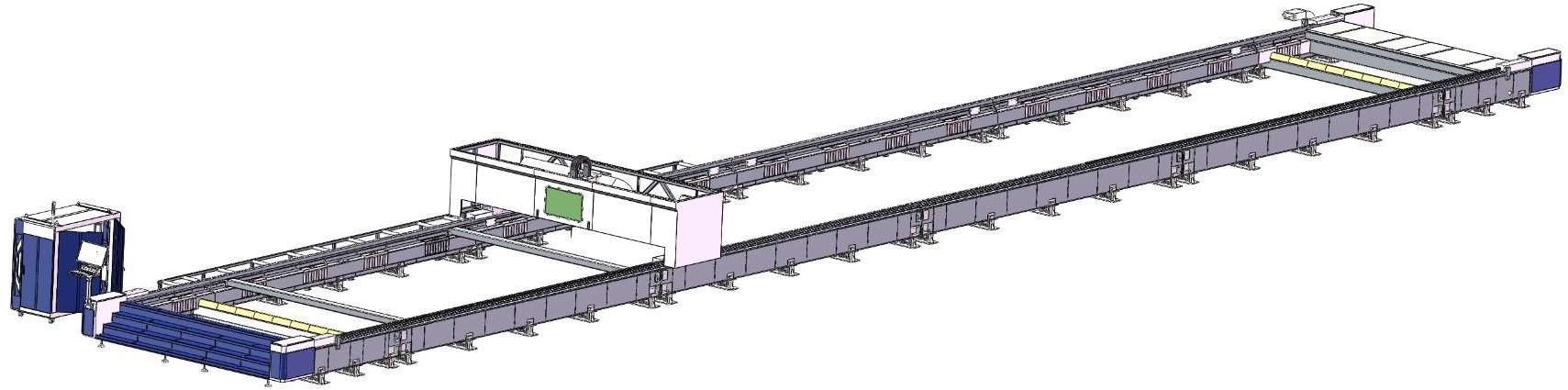

For certain heavy-duty industries, such as shipbuilding, steel structure fabrication, and high-power job shops, a standard cutting table is not sufficient. These industries require a super-long table fiber laser cutting machine combined with ultra-high laser power to efficiently process oversized metal plates with high precision and productivity.

To meet these demands, our Gantry Type Ultra-High Power Fiber Laser Cutting Machine is specifically designed for long-length, heavy-plate, and high-power cutting applications.

For international customers, machine transportation is a critical consideration.

Taking a 12025 single-table open-type fiber laser cutting machine as an example, the overall width exceeds the standard container size. In this case, a 40FR (Flat Rack) container is required, which significantly increases shipping costs.

To solve this issue, our gantry type high power laser cutting machine adopts a modular and sectional body design:

The machine body can be disassembled into sections for transportation

After arrival, the machine is reassembled on site

This design allows shipment using standard containers, greatly reducing international logistics costs

In contrast, the SPARK-H ultra-high power laser cutting machine uses a fully integrated body structure that cannot be disassembled, meaning it must be shipped as a complete unit, resulting in higher transportation expenses.

Many customers are concerned whether reassembly will affect cutting accuracy.

After installation, we use a dual-axis photoelectric collimator to precisely align the entire gantry structure

This ensures the machine bed, rails, and gantry are perfectly collinear

Once collimated, the original cutting precision is fully maintained, with no loss of accuracy

For ultra-high power applications, bevel cutting is often essential, especially in shipbuilding and steel construction.

Our gantry type fiber laser cutting machine supports a mature and market-proven bevel cutting system

This technology has been widely applied and verified in real industrial production

It enables V, Y, X, and K bevel cutting, improving welding efficiency and reducing secondary processing

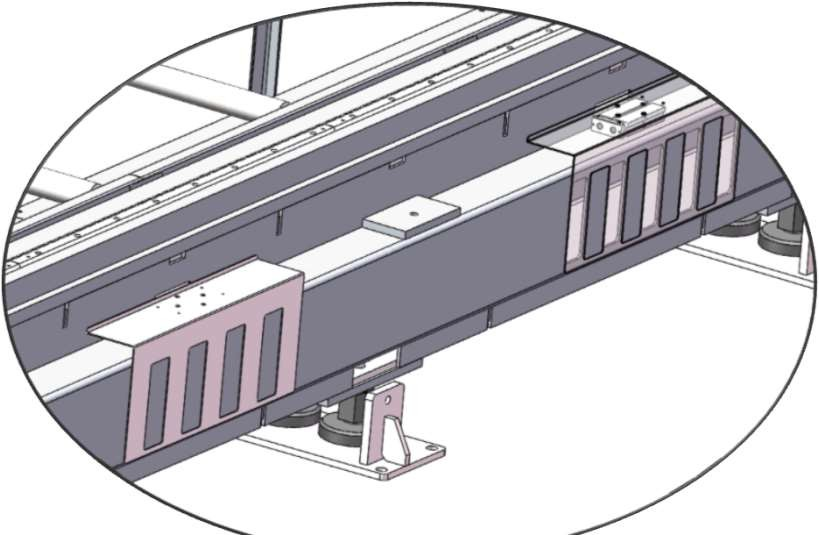

High-power cutting of thick carbon steel generates a large amount of smoke and dust.

Each side of the machine is equipped with a smoke collection device spaced at 1.4 meters

This design ensures fast and efficient fume extraction directly at the cutting area

It significantly improves factory air quality and complies with environmental and safety standards

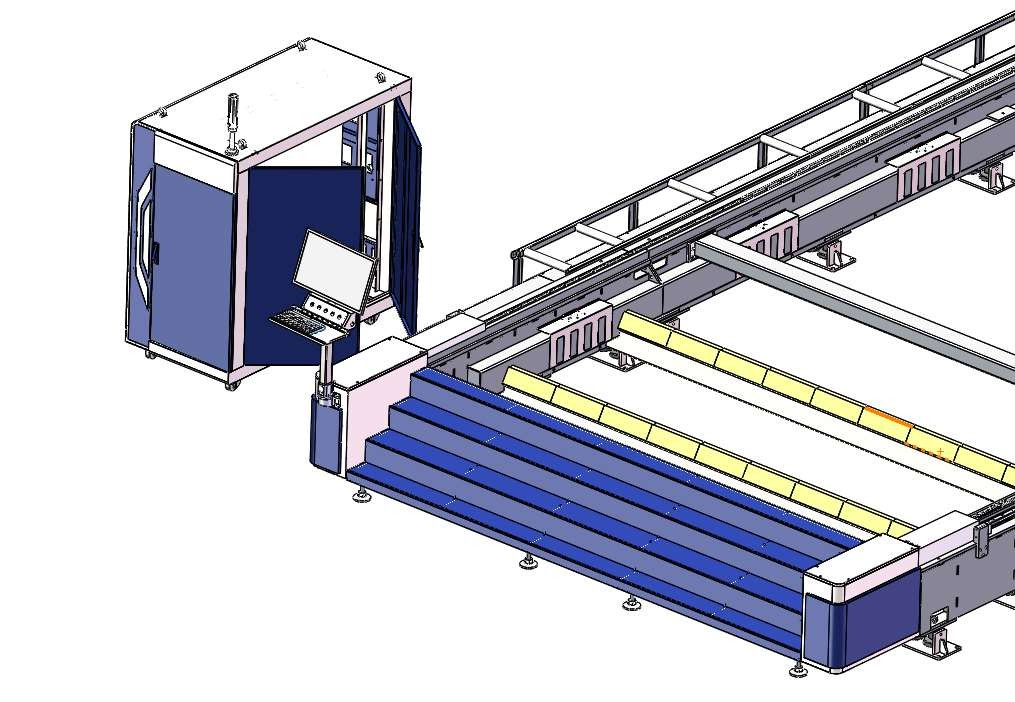

The machine adopts a step-type design, which offers:

Easier access for operators

Improved safety during operation and maintenance

Higher convenience for large-format and long-plate processing

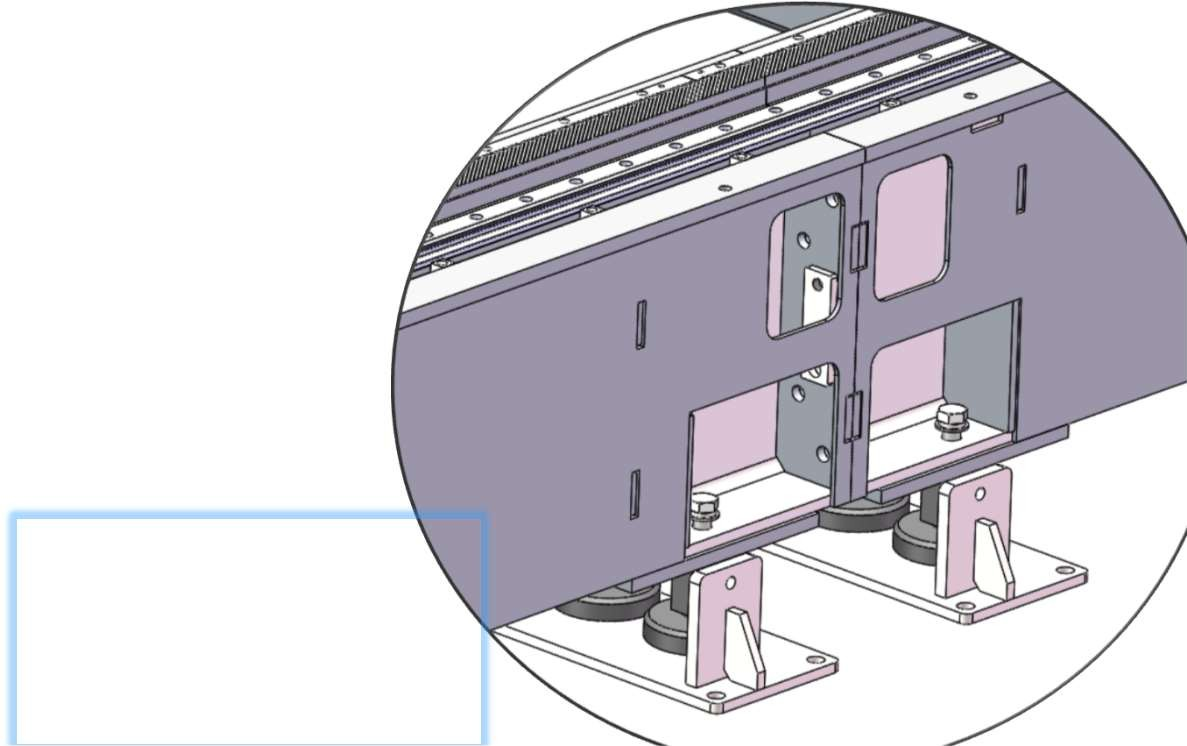

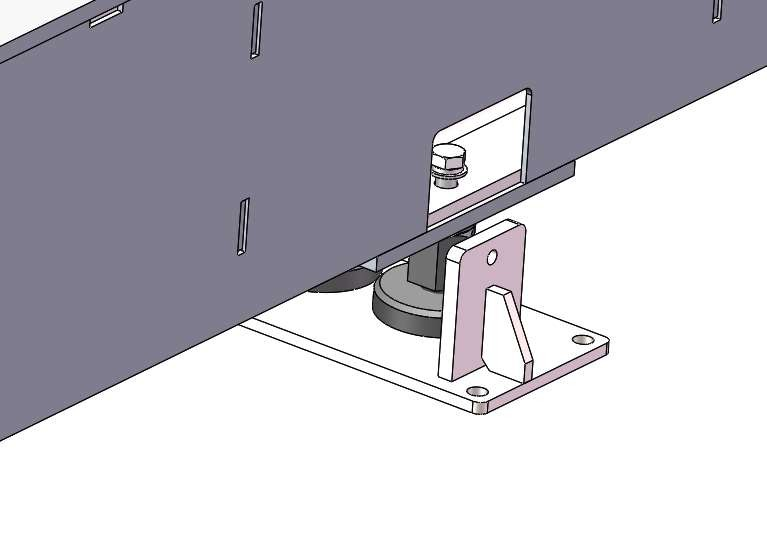

The machine is equipped with adjustable support feet:

Allows slight up-and-down adjustment

Ensures optimal leveling on different factory floors

Enhances long-term operational stability and cutting accuracy

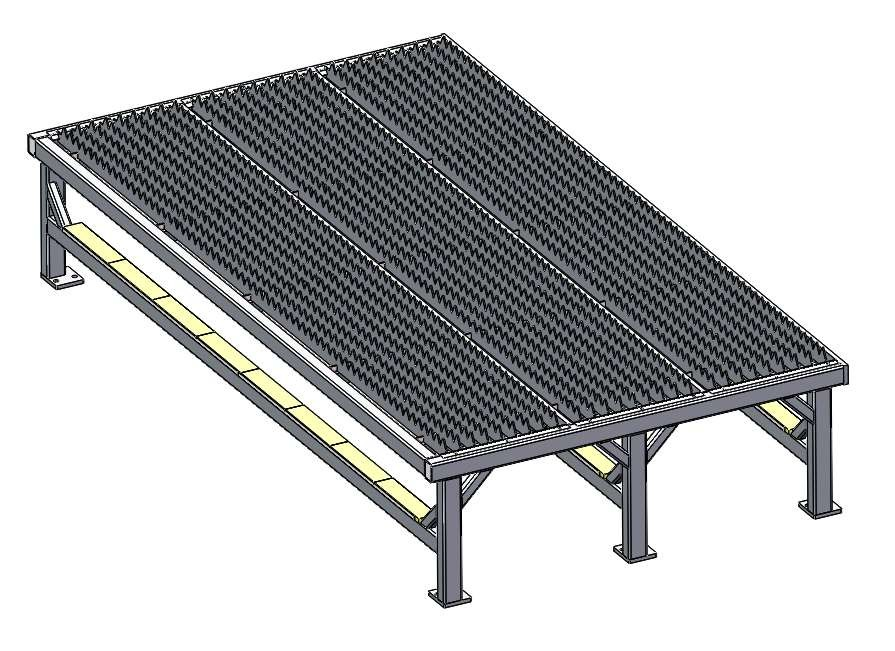

The working table is designed with 2-meter modular sections:

Each section is 2 meters long

The total table length can be extended without limitation

Ideal for long-table fiber laser cutting machine applications and oversized metal plates

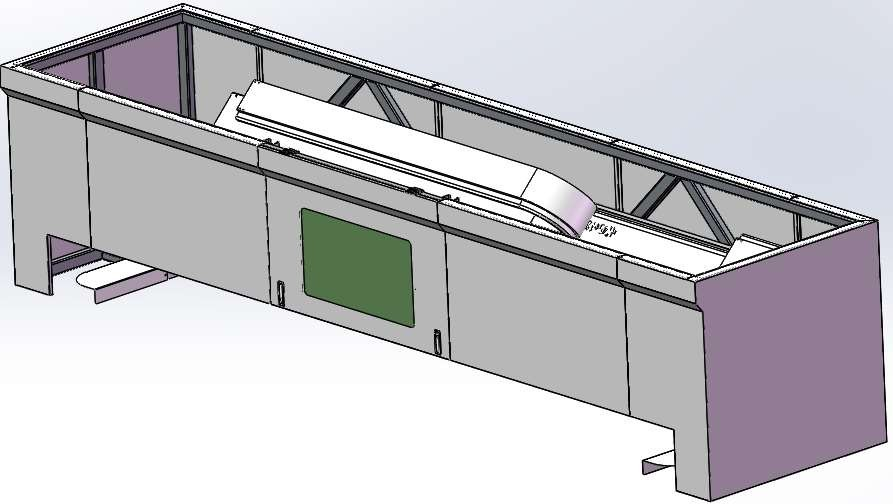

The gantry structure adopts a full-cover enclosed design, which offers multiple advantages for high-power laser cutting operations:

The enclosed gantry makes smoke, dust, and metal particle collection more efficient, especially during ultra-high power and thick-plate cutting

It helps maintain a cleaner working environment and reduces dust accumulation on precision transmission components

The gantry cover is designed with a modular structure, allowing fast disassembly when maintenance is required

This modular design enables easier and quicker access to the laser cutting head, significantly reducing maintenance time and improving service efficiency

Overall, it enhances machine reliability, long-term stability, and operating safety for gantry type high power laser cutting machines

Shipbuilding industry

Heavy steel structure fabrication

Bridge and construction machinery

High-power metal processing job shops

Extra-long and thick plate cutting applications

The Gantry Type Ultra-High Power Fiber Laser Cutting Machine combines:

Super-long table design

Ultra-high laser power

Modular transportation structure

High-precision assembly technology

It is the perfect solution for customers who require a super-long table fiber laser cutting machine with high power, high precision, and optimized shipping costs.

Do not hesitate to give us a call or drop off a message if you have any question.