Compared with a sheet fiber laser cutting machine, selecting a pipe (tube) laser cutting machine requires more detailed technical consideration. This is because pipe cutting is a dynamic 3D cutting process, involving rotation, clamping, gravity, and vibration, while sheet cutting is mainly a 2D linear movement.

For sheet metal laser cutting, once the sheet size and maximum material thickness are confirmed, it is relatively easy to choose a suitable machine. However, for a pipe laser cutting machine, multiple additional parameters must be evaluated to ensure stable cutting performance, precision, and automation capability.

Below are the key points to fully understand and correctly select a fiber laser pipe cutting machine:

The first and most critical factor is the pipe diameter.

For round pipes, selection is based directly on the outer diameter (OD).

For square or rectangular pipes, the equivalent round diameter must be calculated.

Example:

A square pipe of 100 × 100 mm

Equivalent round outer diameter:

100 × 1.414 ≈ 141 mm

In this case, a 160 mm chuck diameter should be selected to ensure safe clamping.

Correct chuck size selection is essential for cutting stability and accuracy in any tube laser cutting machine.

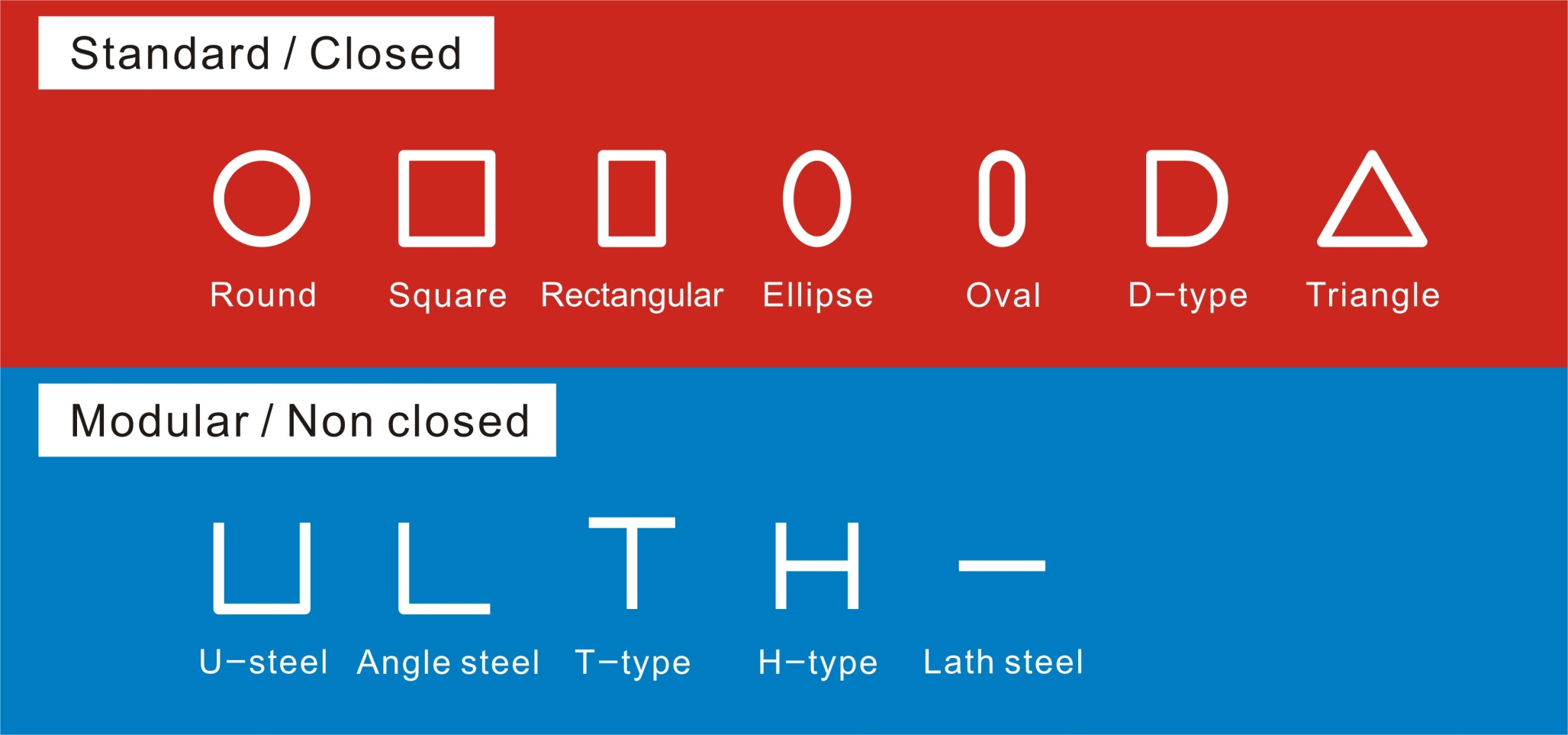

Common pipe shapes include:

Round

Square

Rectangular

These shapes are generally suitable for automatic loading systems.

Special profiles such as:

C-channel

H-beam

L-profile / angle steel

usually require semi-automatic loading, due to their asymmetrical structure and clamping difficulty.

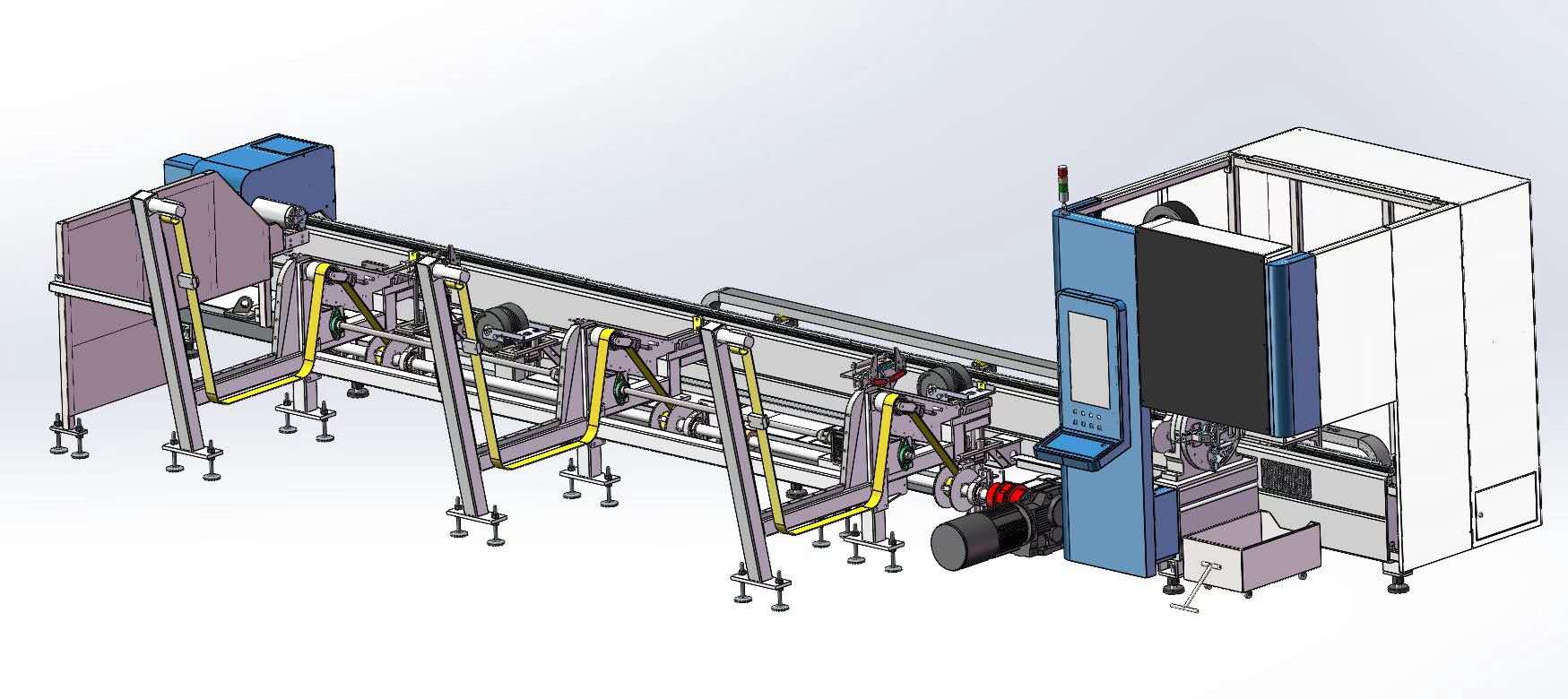

The most common pipe lengths are:

6 meters (standard)

12 meters (extended)

Pipe length directly affects machine configuration, loading system design, and chuck quantity.

Pipe thickness has a direct impact on laser source power selection.

Unlike sheet cutting, pipe cutting has a special challenge:

Corner thickness is greater than side thickness, especially for square and rectangular pipes

As a result, cutting speed at corners is slower, and insufficient laser power may lead to poor cut quality

Therefore, pipe laser cutting machines often require higher power compared with sheet cutting machines of the same nominal thickness.

Material type is another key factor affecting laser power and cutting performance.

Common materials:

Carbon steel (CS)

Stainless steel (SS)

Special materials:

Copper

Brass

Aluminum alloys

High-reflective materials such as copper and brass must be clearly specified in advance, as they require higher laser power and specialized cutting parameters.

The load capacity of the chuck system is limited.

Typically, a dual-chuck pipe cutting machine supports up to 300 kg

If the single pipe weight exceeds this limit, machine structure and configuration must be re-evaluated, such as:

Heavy-duty chucks

Additional supports

Customized machine design

In regions with high raw material costs, customers often require minimum tail waste.

For large-diameter or heavy-duty pipes, rear waste control becomes especially important. Advanced pipe laser cutting machines can significantly reduce leftover material, improving overall material utilization.

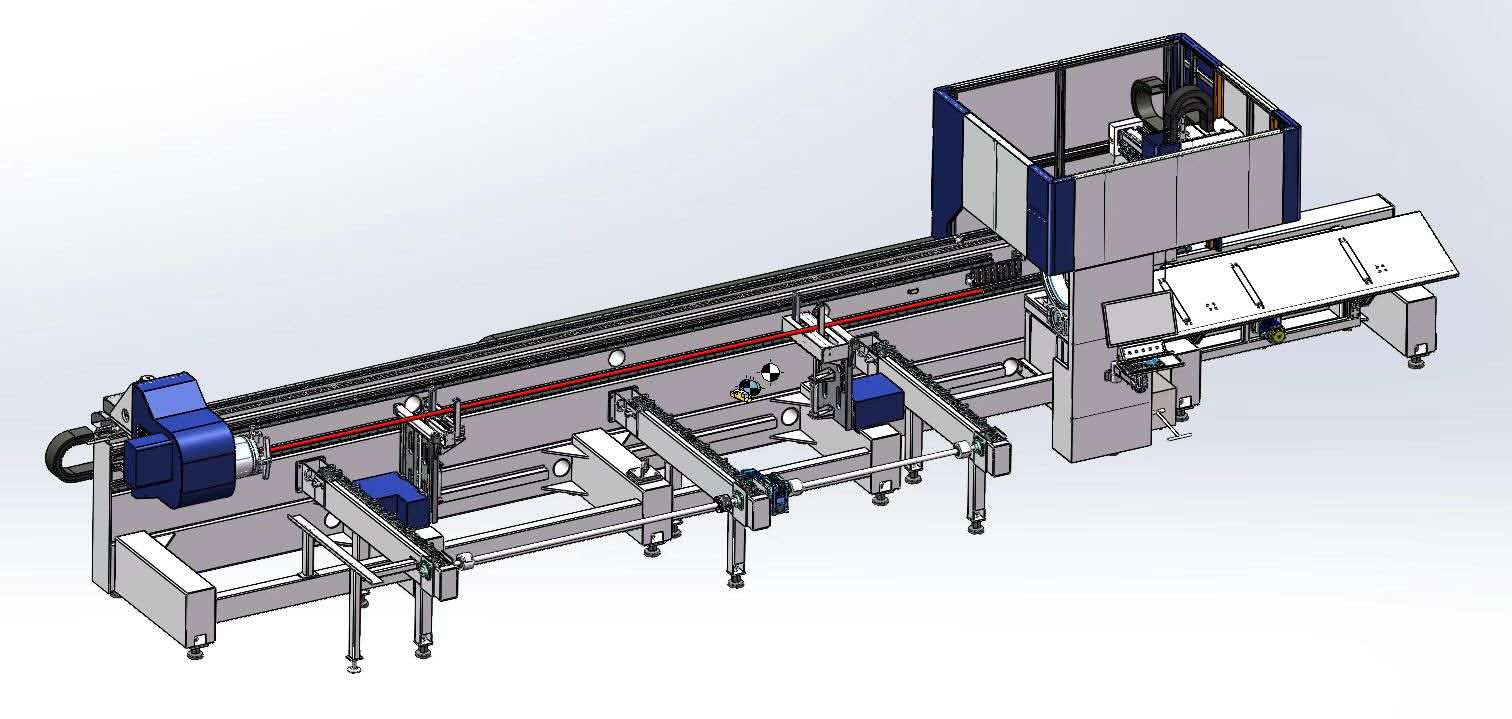

The required finished part length directly determines how many chucks are needed.

For 6 m pipes, the maximum unsupported finished part length with dual chucks is usually up to 3 m

If the finished part length exceeds 3 m, a three-chuck pipe laser cutting machine is strongly recommended

A 3-chuck design provides better support, reduces vibration, and ensures higher cutting accuracy for long parts.

For customers with welding requirements, a bevel cutting function is often essential.

Bevel cutting:

Improves welding quality

Reduces secondary processing

Is commonly used in structural steel, frames, and heavy fabrication industries

Modern fiber laser pipe cutting machines can support automatic bevel cutting for higher production efficiency.

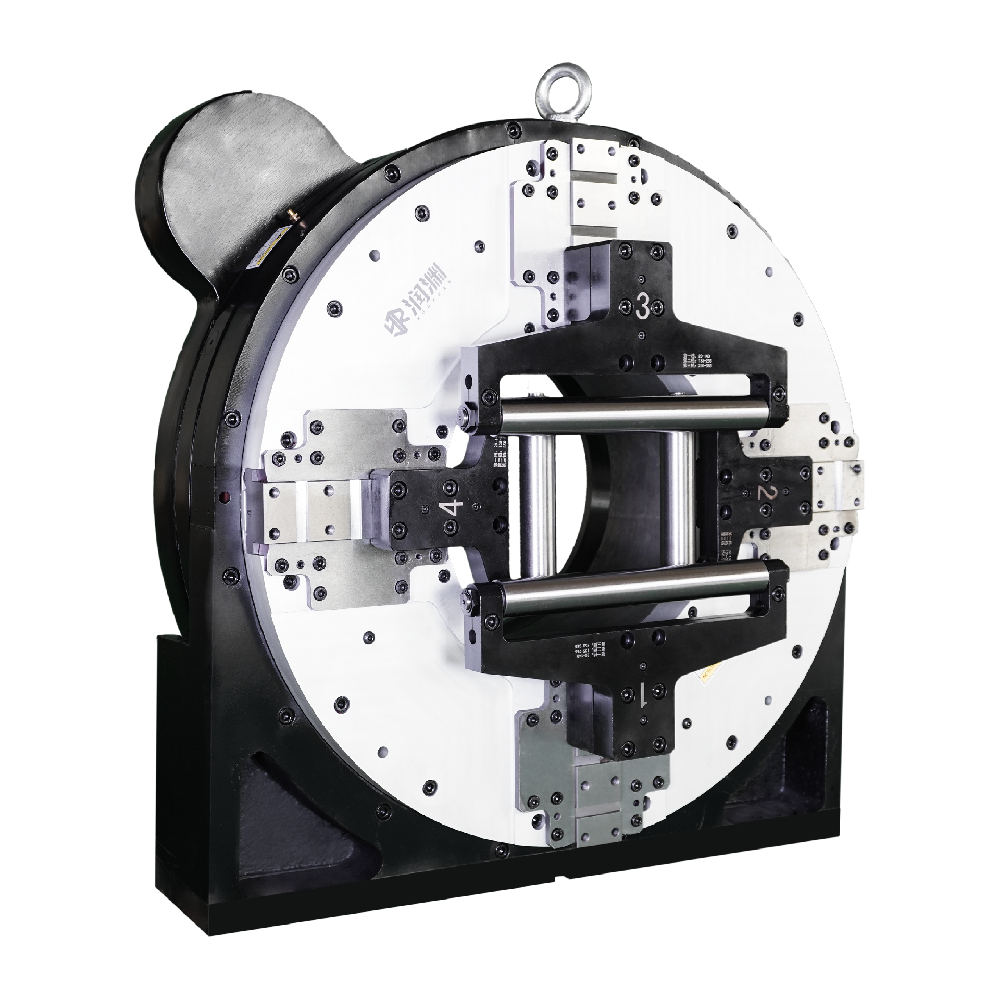

The most important for the pipe cutting machine is the precision chucks

It must have the heavy duty loading capability & Good sealing performance

It simplifies complex CNC machine operation and integrates CAD, Nest and CAM modules in one. From drawing, nesting to workpiece cutting all can be finished by a few clicks on big IPAD Screen. Realize the intelligent diagnosis, multi-threading operation, three-level perforation, laser energy control, adaptive edge-finding, automatic corner acceleration and deceleration, flight cutting, switching worktables, mechanical accuracy compensation etc.

Pneumatic clamp design on both sides. The dual-chucks help reduce tube vibration to a minimum, guaranteeing high accuracy in even complex tube configurations at high cutting speed.

Currently from China, the brands "Runyuan" and "Dairuike" is a good brand for the precision chucks especially for the heavy duty and high speed running etc.

In conclusion, choosing a high-quality pipe (tube) laser cutting machine requires a comprehensive evaluation of multiple factors, including a reliable CNC control system, premium core components, and extensive application experience in tube cutting technology

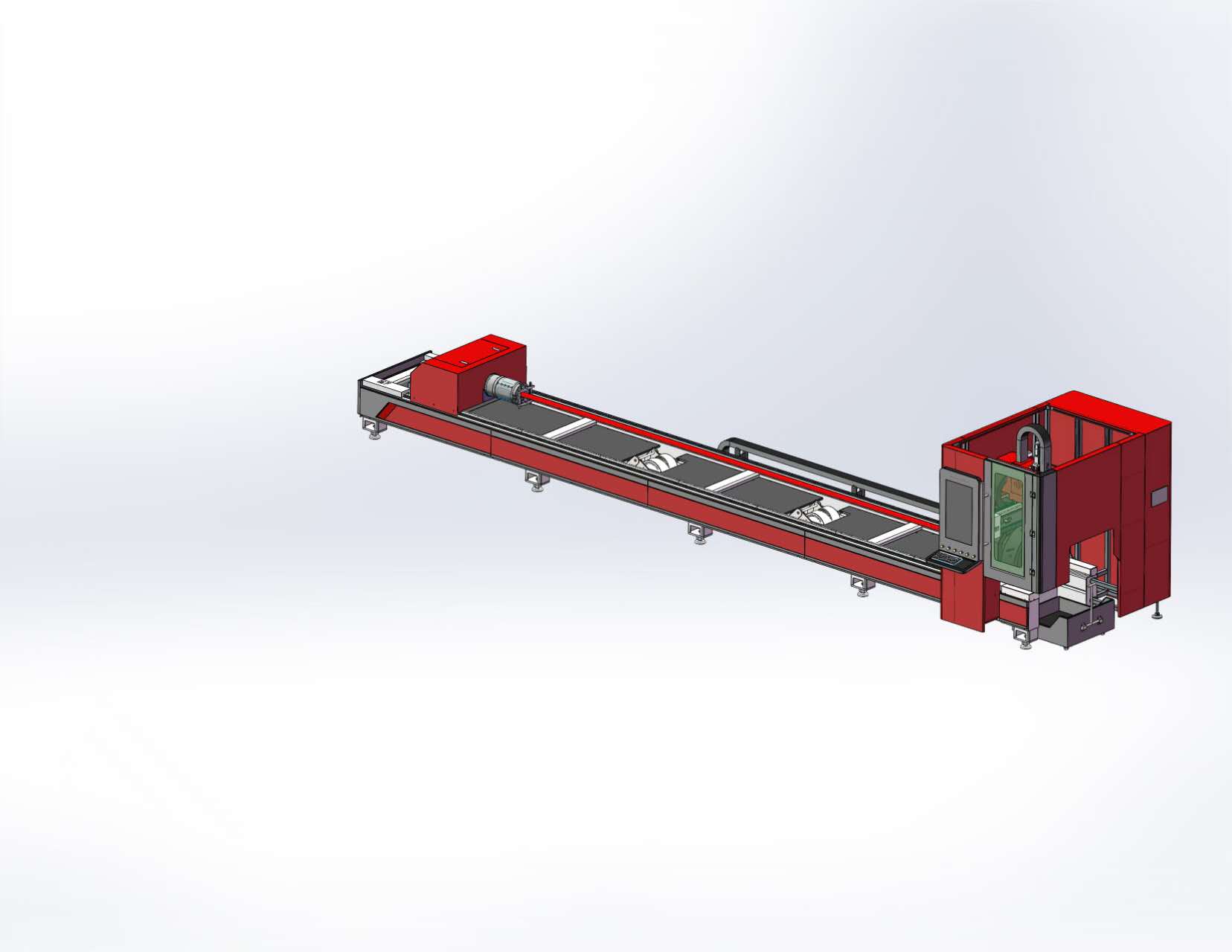

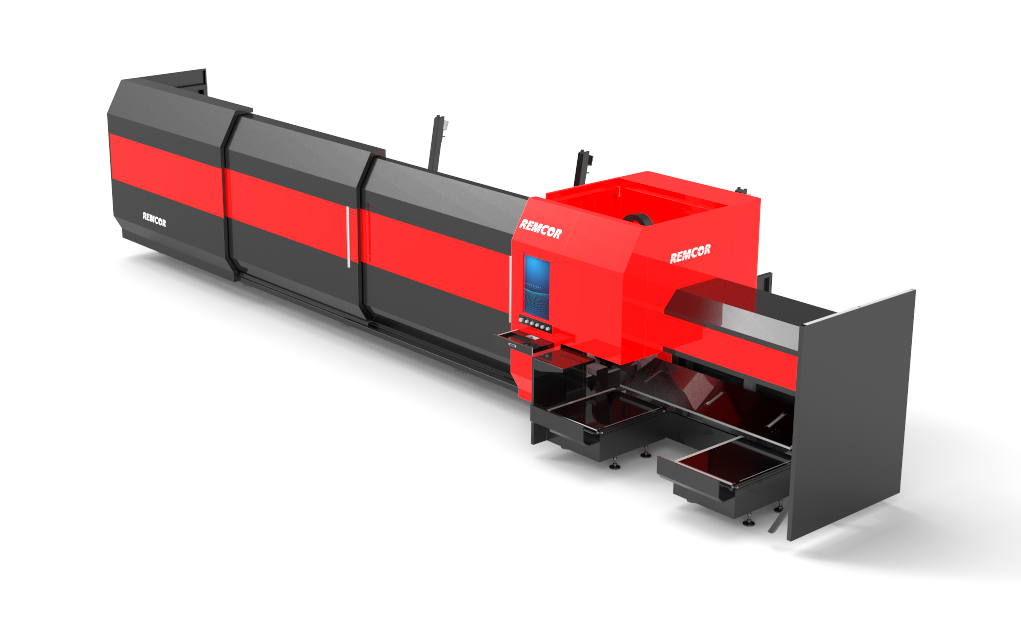

Is it possible to add a full protective cover and meet CE requirements for European and North American customers?

Yes, absolutely.

We offer a full cover design for our 2 chucks tube fiber laser cutting machine, specifically developed to comply with CE qualification and international safety standards. This enclosed structure is not only popular among European customers, but also mandatory in many European and North American markets due to strict workplace safety regulations.

We have already developed mature and proven engineering drawings for a full cover tube fiber laser cutting machine that fully meets CE safety standards. The enclosed design effectively prevents laser radiation leakage, flying sparks, and metal debris, ensuring maximum operator protection during high-speed tube cutting operations.

This full cover 2 chucks tube fiber laser cutting machine is designed for stable, long-term industrial use and has been widely accepted in CE-regulated markets.

To further enhance workplace safety and environmental protection, the machine is equipped with an efficient dust and smoke extraction system. This system:

Effectively removes cutting smoke and metal dust

Maintains a clean and safe factory environment

Meets European requirements for environmental protection and operator health

The fully enclosed structure combined with the dust collection device significantly improves overall working conditions.

The full cover tube fiber laser cutting machine is especially suitable for:

European customers requiring CE-certified laser machines

North American customers with high safety expectations

Factories focusing on clean production and operator protection

This design reflects both regulatory compliance and modern industrial aesthetics, making it a preferred solution in high-end markets.

Our full cover 2 chucks tube fiber laser cutting machine combines:

CE-compliant full enclosure design

Proven and mature engineering drawings

Integrated dust collection system

Enhanced safety and clean working environment

It is an ideal tube laser cutting solution for customers in Europe, North America, and other regions with strict safety standards.

Do not hesitate to give us a call or drop off a message if you have any question.