Jan 30 , 2023

This customer is from Thailand, operating a small job shop that mainly cuts customized parts according to different customer requests. Before working with us, they already owned several laser cutting machines from other brands.

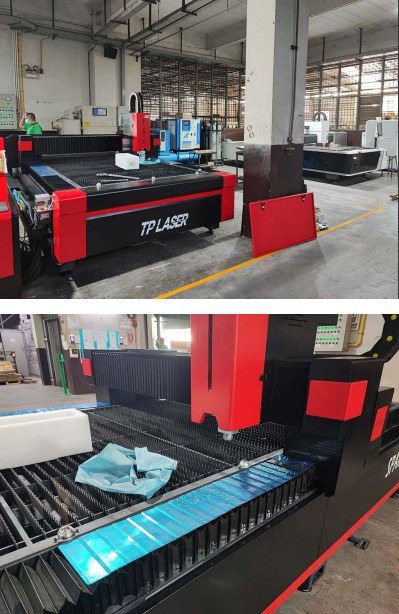

Four months ago, they purchased their first 3000W fiber laser cutting machine (3000 × 1500 mm single table) from us. As their business volume increased rapidly, they needed to improve productivity, cut thicker materials, and expand their laser cutting machine application.

After the new machine was installed and tested in our laser machine factory, the customer immediately noticed that our machine cuts significantly faster than their previous machines, even though their old machine had only been used for four months.

They asked us: “Why is this machine faster?”

Below are the key reasons, explained clearly and orderly.

When a sheet metal fiber laser cutting machine runs at higher speed, a strong and stable machine body is essential.

Our 3015 single-table laser cutting machine weighs up to 3000 kg

The heavy-duty welded structure effectively absorbs vibration

Even at high acceleration and cutting speed, the machine does not shake, ensuring better accuracy and edge quality

This solid foundation allows the machine to run faster and more stably than lighter machines.

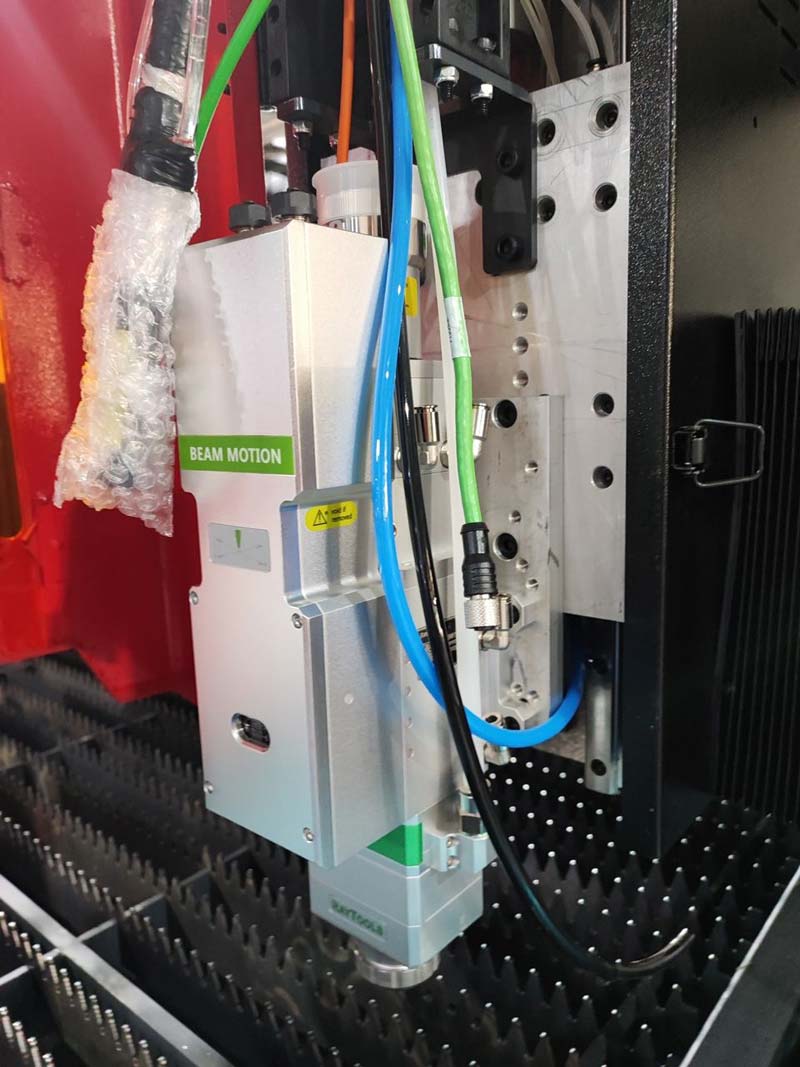

We use a one-time casting gantry design, which provides two major advantages:

Reduced gantry weight, lowering the load on the servo motors

Higher rigidity, improving dynamic performance and cutting precision

This optimized gantry structure enables faster movement without sacrificing stability, which is critical for high-speed laser cutting machine applications.

A heavier and stronger machine body requires powerful servo motors to fully utilize its performance.

Y-axis servo motor: 1300W

X-axis servo motor: 850W

We use Yaskawa servo motors, known for stronger driving force, faster response, and long-term reliability

Many domestic brands only use 850W servo motors on the Y-axis, which limits acceleration and cutting speed. Our configuration ensures smoother, faster, and more reliable operation.

Cutting speed is not only about hardware—it also depends heavily on cutting parameters.

Previously, the customer operated machines by themselves with limited understanding of cutting parameters

This time, our engineers spent extra time optimizing cutting parameters for different materials and thicknesses

We provided in-depth guidance and training, ensuring the customer fully understands how to maximize machine performance

As a result, the 3000W fiber laser cutting machine now runs at its true potential.

Our core design philosophy is to provide:

Reliable machine structure

Strong cutting performance

Competitive pricing for real business growth

Thanks to the optimized mechanical design, high-quality components, and professional technical support, our machine delivers higher efficiency and faster cutting speed than many competitors in the same power range.

With this upgrade, the customer has successfully expanded their laser cutting machine application to thicker materials and more diverse sheet metal jobs, greatly increasing productivity and profitability.

This is the first one.