Feb 02 , 2026

A coil fed laser cutting machine is the ideal solution for manufacturers seeking higher efficiency, continuous production, and lower material cost in modern sheet metal processing.

Compared with traditional sheet cutting, a coil sheet metal laser cutting machine enables automatic feeding from metal coils, reducing manual handling, minimizing material waste, and significantly improving productivity.

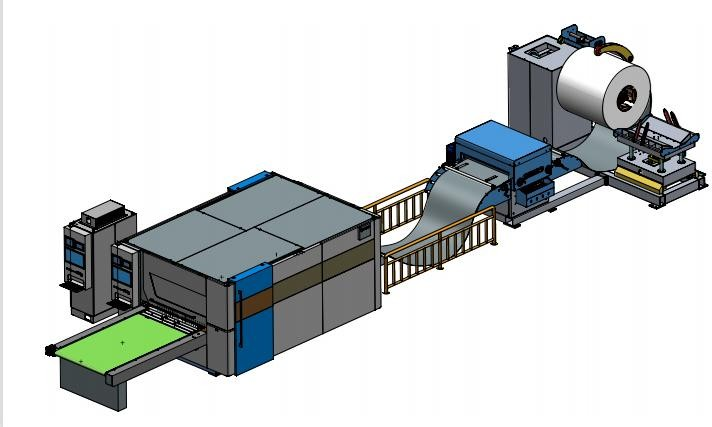

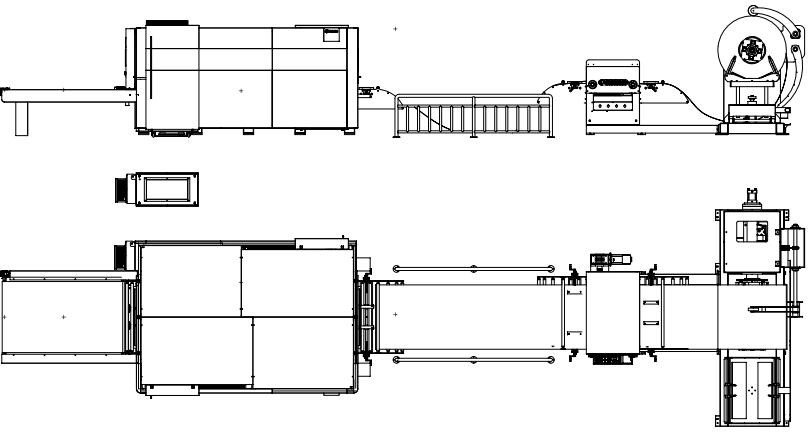

The complete working process of a coil sheet laser cutting machine includes:

Loading trolley

De-coiler

Levelling unit

Fiber laser cutting unit

Transportation table

Manual unloading

This fully integrated workflow makes the coil fed laser cutting machine a key solution for high-volume, flexible, and automated sheet metal cutting lines.

The loading trolley is designed to transport metal coils safely and efficiently to the decoiler.

Advantages:

Maximum loading capacity up to 15 tons, suitable for heavy metal coils

Hydraulic motor driving system ensures smooth movement

Hydraulic cylinder lifting system aligns the coil precisely with the decoiler main shaft

Reduces labor intensity and improves loading efficiency

Enhances safety for coil sheet metal laser cutting machine operations

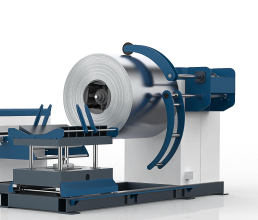

The decoiler is a critical unit for any coil laser cutting machine, directly affecting feeding stability and cutting accuracy.

Structural Advantages:

Main frame made of square tubes, Q235 steel plates, and 45# steel

Fully stress-relieved by annealing to prevent deformation

Front and rear bearing holes bored in one process to ensure spindle concentricity and zero radial runout

Key Components:

Spindle: Made of 45# seamless steel pipe, quenched and tempered for high strength

Hydraulic expansion system: Connecting-rod type push-pull expansion drum

Pressing device: Polyurethane-coated pressing wheel, cylinder-controlled support arm

Material supporting system: Support arms and rolling cylinders driven by servo motor and reducer

Thickness & Power Matching:

Standard coil thickness: 1–3mm, suitable for 3000W coil sheet laser cutting machine

Heavy-duty applications: 3–6mm coil thickness, supported by reinforced decoiler design

Recommended laser power: 6000W or 12000W fiber laser, ideal for thick coil sheet metal cutting

This makes the system highly adaptable for different coil fed laser cutting machine applications.

To ensure flat and stress-free sheet feeding, the leveling unit plays a vital role in the coil sheet metal laser cutting machine.

Technical Advantages:

17 leveling rollers (8 upper + 9 lower) for superior flatness control

Rollers driven by servo motor and precision gearbox

Roller material: alloy steel with quenching, tempering, high-frequency hardening, and hard chrome plating

Planar correction accuracy: ≤ 1.5mm/㎡

This ensures excellent sheet flatness before entering the fiber laser cutting area, greatly improving cutting quality and consistency.

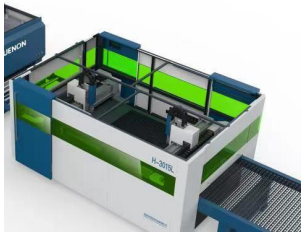

The laser cutting unit is specially designed for continuous coil feeding and high-speed processing.

Advantages:

Compact structure with minimal footprint, ideal for factories with limited space

Modern and clean appearance, suitable for automated production lines

Designed specifically for coil laser flexible cutting machine applications

Machine Bed Structure:

Dual integrated welding bed design

Entire bed welded as one piece and stress-annealed

Manufacturing process:

Welding → Stress annealing → Rough machining → Finishing machining

Effectively eliminates internal stress and ensures long-term stability

Key Benefits:

Excellent vibration resistance during high-speed cutting

Long-term precision retention

Ideal for continuous operation of coil fed laser cutting machines

Continuous coil feeding for higher productivity

Reduced material waste and lower processing cost

Less manual handling, improved safety

High flatness accuracy for better cutting quality

Flexible thickness range (1–6mm coil sheet metal)

Compatible with 3000W / 6000W / 12000W fiber laser sources

Compact footprint suitable for modern factories

Long-term machine stability and precision

A coil sheet metal laser cutting machine is no longer just an option—it is a strategic upgrade for manufacturers pursuing automation, efficiency, and cost control.

With a robust loading trolley, high-precision decoiler, advanced leveling system, and stable fiber laser cutting unit, the coil fed laser cutting machine provides a complete and reliable solution for modern coil processing.

If you are looking for a coil laser cutting machine or coil laser flexible cutting machine for high-volume sheet metal production, this system is the ideal choice for long-term competitiveness and stable output.

This is the first one.