Jan 12 , 2026

In modern metal fabrication, coil fed laser cutting machines and coil fed punching machines are two highly efficient solutions for processing metal coils into finished parts. While both systems are designed for continuous, automated production, their working principles, productivity, and applications differ significantly. Understanding these differences helps manufacturers choose the right solution for their production needs.

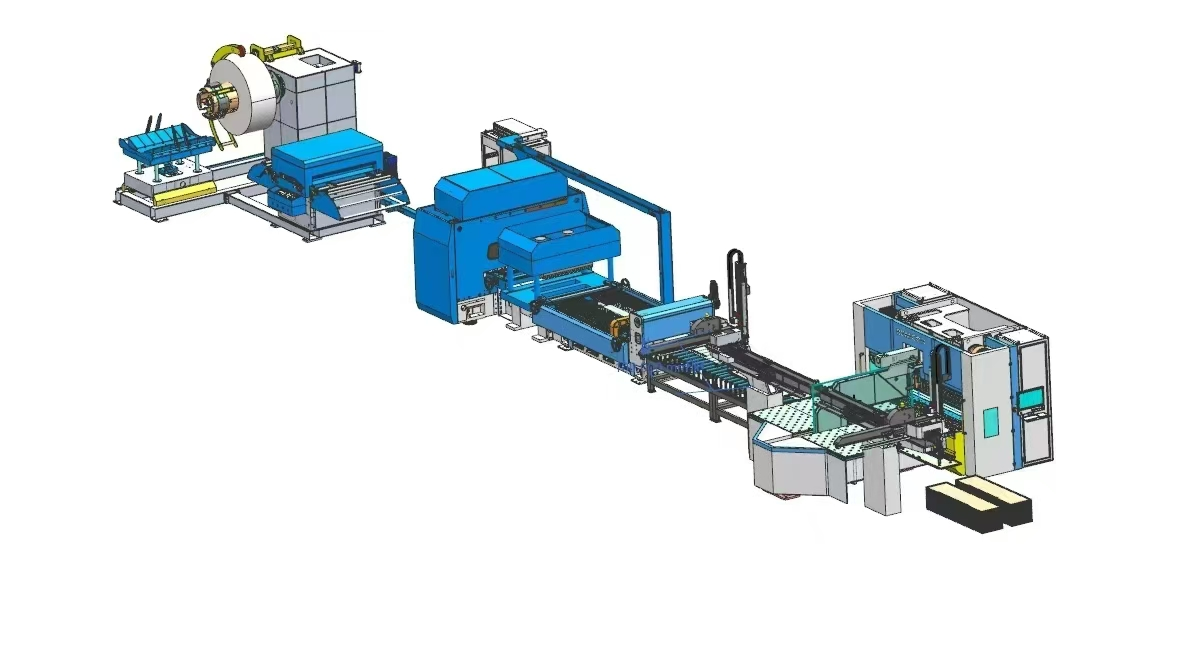

A coil fed laser cutting machine integrates decoiling, leveling, feeding, and laser cutting,table for receive into one continuous production line. Metal coils are automatically uncoiled and flattened, then fed into a high-precision laser cutting system. The laser beam melts or vaporizes the material according to CAD drawings, allowing flexible, mold-free cutting of complex shapes.

Key characteristics:

Non-contact cutting process

High precision and clean cutting edges

No need for dedicated tooling or molds

A coil fed punching machine also uses a decoiler and feeder, but the material is processed through a Hydraulic or servo punching press.after punching then will be shearing. The machine uses pre-designed punching dies to stamp holes, shapes, or contours into the metal strip in a continuous operation.

Our machine working principle is same as Pivatic from Finland, which is a famous brand in the world, but compared with Pivatic, definitely our technology is also stable and is much more attractive by our prices

So maybe maybe worry about our machine stability and efficiency, here we can list some of our international customers for reference

It is a customer from Russia, customer name is short for Promet(https://www.safe.ru/en/ ),actually they are the biggest in European for the furniture processing

This customer purchased several lines from Pivatic, but can not replace the parts by the western sanctions, so they are very glad to have a try and after some time use, finally they are quite happy by our extreme quality

Currently we have 2 lines running in their factory. one line already running for more than 5 years until now without any kind of problems

Key characteristics:

Contact processing with punching dies

Extremely fast for repetitive shapes

Requires tooling investment for each design

When comparing efficiency, both machines excel in different scenarios:

Punching machines are generally faster for high-volume, repetitive production, especially for simple geometries such as round holes or standard slots. Once the tooling is installed, production speed is extremely high.

And the production cost per each piece is much lower than Coil fed laser cutting machine, especially from the electric cost, and total lines is 24 hours automatic stop without human operation once load the material.

Laser cutting machines offer superior efficiency for small-batch, multi-variety, or frequently changing designs. No die change is required, which significantly reduces setup time and improves overall production flexibility.

In summary:

High volume + simple parts → Coil Fed Punching Machine

Flexible design + complex shapes → Coil Fed Laser Cutting Machine

Electrical cabinets and enclosures

Automotive structural and functional parts

Home appliance panels

Precision metal components with complex contours

Laser cutting is ideal when design flexibility, accuracy, and fast product iteration are critical.

Metal brackets and frames

Ventilation panels and perforated sheets

Standardized industrial parts

Mass-produced components with fixed designs

Punching machines are preferred for long-term, stable production where part geometry does not change frequently.

Now for the completed production lines, we can connect with the Panel bender or Press brake, and also after the Panel bender, we can add the modular of the welding machine into one line

So the flow will be the below

Decoiler+ Levelling+ Punching + 50T Independent punching+ Shearing+ Press brake+ Conveyor transportation + Welding machine

50T punching unit is mainly for the multi holes processing, which is more faster by one time punching

Here is the layout of our ideas for reference

Remcor Technology is a professional manufacturer and solution provider specializing in coil fed laser cutting lines, coil fed punching machines, and intelligent metal processing systems. With a strong focus on automation, efficiency, and reliability, Remcor Technology helps customers worldwide improve productivity and reduce manufacturing costs.

Our advantages include:

Customized coil processing solutions

Advanced automation and control systems

Stable machine performance for continuous production

Professional technical support and global service capability

Whether you require high-speed punching solutions or flexible coil fed laser cutting systems, Remcor Technology is committed to delivering equipment that matches your production goals.

Looking for the right coil processing solution?

Contact Remcor Technology to explore how our coil fed laser cutting machines and punching machines can optimize your metal fabrication line.