Nov 26 , 2025

What Cannot Be Cut with a Laser Cutting Machine – Technical Explanation and Safe Alternatives

Laser cutting machines have become essential in modern manufacturing, metal fabrication, advertising, automotive, electronics, and precision engineering. Their high speed, accuracy, and non-contact material processing make them ideal for a wide range of industrial applications. However, not all materials are suitable for laser cutting. Understanding why certain materials cannot be processed by a laser cutting machine is critical for safety, efficiency, and machine longevity.

The following professional guide explains the technical reasons behind these limitations while highlighting safe alternatives. As a trusted industry supplier of advanced laser systems, Remcor Technology provides professional guidance to ensure safe and optimal operation of every laser cutting machine.

Laser Type | Wavelength Range (nm) | Typical Applications |

Gas Laser | 10,600 (CO2), 632.8 (He-Ne), Various (Ar, Kr) | Cutting, engraving, medical procedures, spectroscopy |

Solid-State Laser | 1,064 (Nd:YAG), 532 (Nd:YAG), 1,550 (Er:YAG) | Material processing, laser marking, medical procedures |

Semiconductor Laser | 780–1,550 (InGaAs, GaN, GaAs) | Telecommunications, barcode scanning, laser diode modules |

Dye Laser | Variable (Depends on dye) | Spectroscopy, medical diagnostics, research |

Fiber Laser | 1,064, 1,070, 1,550, etc. | Metal cutting, welding, fiber-optic communication |

Excimer Laser | UV Range (e.g., 193, 248, 308) | LASIK eye surgery, semiconductor manufacturing, micromachining |

Free-Electron Laser | Variable (Wide range including X-ray) | Research, material science, medical imaging |

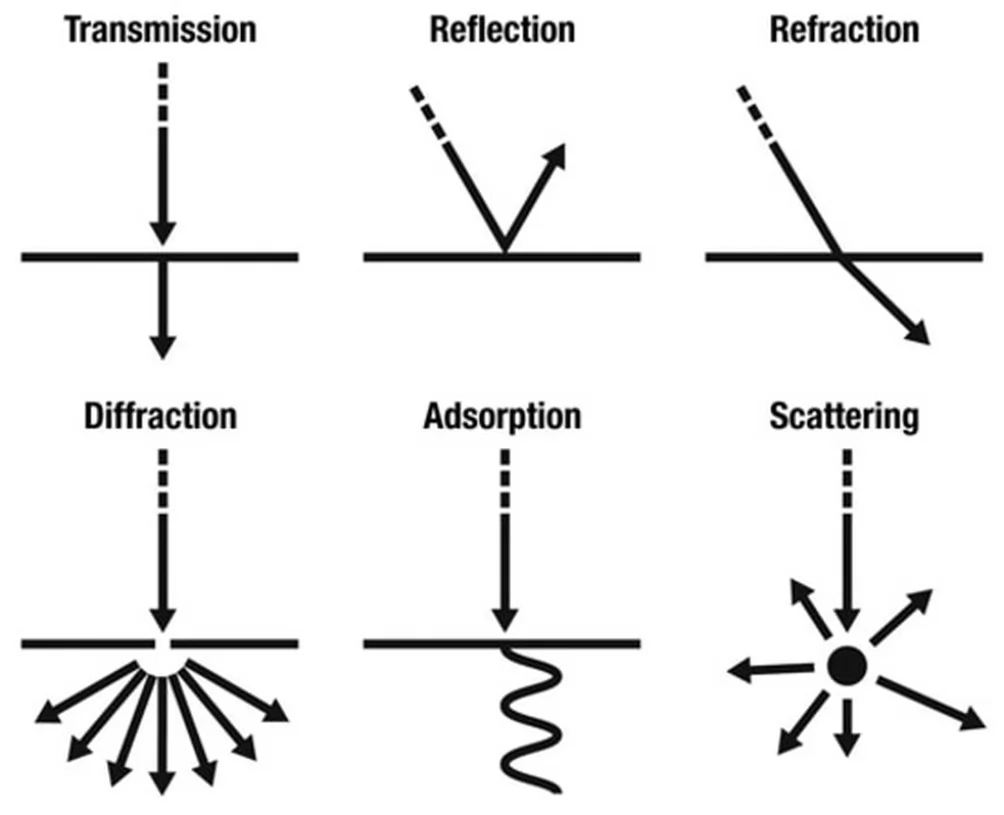

An explanation is very simple – different materials absorb and reflect different wavelengths, therefore, more power is absorbed – easy cutting or engraving will be. More power is being reflected – less power will achieve the surface.

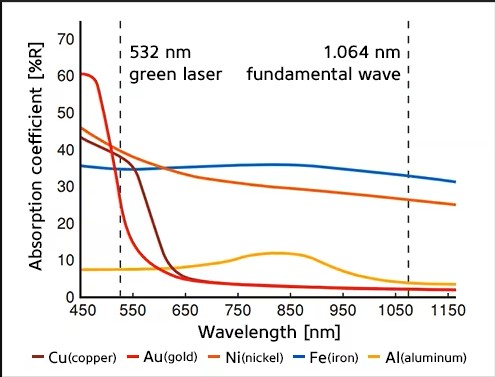

Absorption coefficient depending on wavelength for Copper Gold, Nickel, Iron and Aluminum

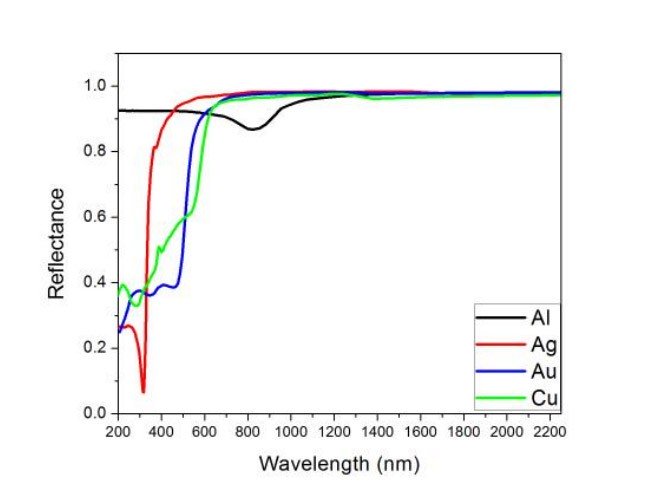

Reflectance for Aluminum Silver Gold and Copper

Under this plot you may see that Al, Ag, Au, Cu reflect almost all wavelengths after 1000 nm.

Examples: Copper, brass, aluminum, gold, silver

Why laser cutting machines struggle:

Reflective metals have a high reflectivity at common industrial laser wavelengths (usually 1064 nm for fiber lasers and 10.6 μm for CO₂ lasers). Instead of absorbing the laser energy, they reflect it back toward the laser source.

Principle explanation:

The cutting process relies on thermal absorption.

If the surface reflects the laser beam, the energy cannot heat or melt the material.

Back-reflected energy can damage the laser optics, lens, collimator, nozzles, and even the laser generator.

Although high-power fiber laser cutting machines with anti-reflection protection can cut certain reflective metals, extreme reflectivity still limits thickness and cutting stability.

Why PVC cannot be cut:

PVC (polyvinyl chloride) contains chlorine, which vaporizes during laser cutting. When exposed to a high-energy laser cutting machine, PVC decomposes and releases hydrogen chloride gas, a toxic and corrosive substance.

Principle explanation:

Laser-induced thermal decomposition breaks C–Cl chemical bonds.

This produces chlorine-based fumes.

These fumes corrode the machine’s internal components, optics, and exhaust system.

It also poses severe health hazards to the operator.

Materials to avoid:

PVC

Vinyl

Artificial leather

Chlorine-containing plastics

Always avoid PVC when using any industrial laser cutting machine.

Even though fiber laser cutting machines excel at cutting stainless steel, carbon steel, and aluminum, extremely thick metals exceed the power and thermal capabilities of the laser.

Why very thick metals cannot be cut effectively:

The laser beam cannot penetrate deep enough to form a stable kerf.

Heat dissipation becomes too slow, causing rough edges or incomplete cuts.

Cutting speed drops drastically, reducing industrial productivity.

Molten material becomes difficult to expel from the cutting gap.

Technical limitations:

CO₂ laser cutters struggle above medium-thickness stainless steel.

Fiber lasers above 20–30 mm thickness require extremely high power (20 kW+).

Industrial economics often make other methods more efficient for thick plates.

Some materials create risks that make them unsuitable for laser processing, regardless of laser type.

Foams or unknown plastics: may ignite or release toxic gas.

Fiberglass: resin produces harmful fumes.

Polycarbonate: burns and produces smoke, leaving melted edges.

Coated materials: paint or surface layers may react unpredictably.

Explosive or flammable materials: extremely dangerous under concentrated laser heat.

Principle explanation:

Laser cutting relies on high-temperature melting, burning, or vaporization. If a material reacts chemically, ignites easily, or decomposes into toxic elements, it becomes unsafe for laser cutting.

Materials that cannot be safely processed by a laser cutting machine still have reliable alternatives.

CNC machining – Ideal for reflective metals or thick plates.

Waterjet cutting – Safe for PVC, vinyl, heat-sensitive plastics, and thick metals.

Plasma cutting – Effective for very thick metal plates

Mechanical cutting (sawing/shearing) – Suitable for composites or chemically reactive materials.

Knife cutting machines – Best for soft plastics, foam, and PVC signage materials.

A laser cutting machine is a powerful tool, but understanding its limitations is essential for safe and efficient industrial production. Materials such as reflective metals, PVC, vinyl, and extremely thick metals require special considerations or different processing methods.

Remcor Technology provides expert guidance, advanced fiber laser cutting machines, and professional consultation to help manufacturers choose the correct processing method for every material.