Feb 06 , 2026

Fiber laser machines have become one of the most important industrial laser technologies in modern manufacturing. Thanks to their high efficiency, low maintenance cost, long service life, compact structure, and excellent beam quality, fiber lasers are now widely used in metal cutting, welding, cleaning, marking, engraving, cladding, and surface treatment across many industries.

In this article, we will systematically explain what fiber lasers can do, starting from the basic laser principle, moving to fiber laser types, functions, industrial applications, and finally limitations of fiber laser technology.

Laser technology is based on the fundamental concept of stimulated emission, first proposed by Albert Einstein in 1916.

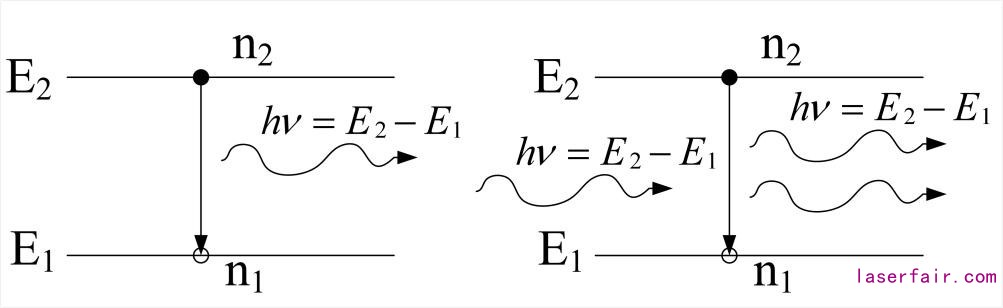

Spontaneous Emission (Left) and Stimulated Emission (Right) In the diagram, the two horizontal lines E2 and E1 represent the energy levels of electrons. The higher the line, the higher the energy of the electron (similar to a higher VIP level). On the left, in spontaneous emission, an electron transitions from a higher energy level to a lower energy level and emits a photon whose energy equals the difference between the two energy levels. On the right, stimulated emission occurs under the influence of an external photon, causing the electron to emit another photon that is exactly identical to the incident one. This is what is meant by “stimulated.” Here we add that hν represents the energy of a single photon, where h is Planck’s constant (which we do not need to focus on here), and ν is the frequency of the light. The frequency directly determines the color of the light we see. Each frequency corresponds to a specific color. The table below lists the frequency and wavelength ranges of visible light. We can see that from red, orange, yellow, green, cyan, blue to violet, the frequency of light gradually increases. This is why in daily life, the higher the temperature of a light source, the more its color shifts toward blue.

As mentioned earlier, stimulated emission is a process in which an external light field induces the emission of a photon that is completely identical to the original one. This incoming photon may come from spontaneous emission or may be an artificially injected seed photon. In any case, once it enters, it will leave together with an identical “twin.” Being “identical” means that the two photons are indistinguishable — essentially a process of copying and amplification. If mirrors are placed at the output of this process, the two photons are reflected back and undergo stimulated emission again, becoming four photons. Repeating this process continuously, the number of photons increases exponentially, and eventually a laser is formed.

Every laser system consists of three essential parts:

The material that produces laser light. In fiber lasers, this is rare-earth-doped optical fiber, such as:

Ytterbium (Yb)

Erbium (Er)

Thulium (Tm)

Provides energy to excite electrons. Usually high-power laser diodes in fiber lasers.

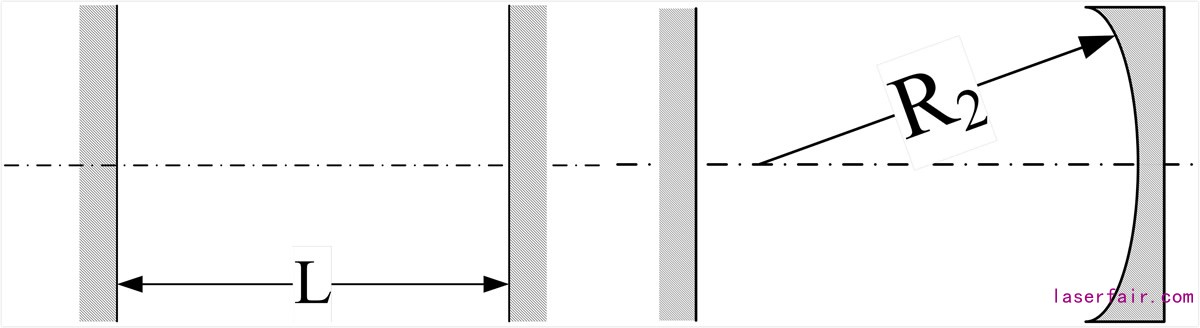

Two mirrors form a cavity where photons bounce back and forth, undergoing continuous stimulated emission and amplification.

One mirror is fully reflective, the other partially reflective. The transmitted light becomes the laser output beam.

Continuous energy output

Used for cutting, deep welding, cladding

Short pulse duration

Used for marking, engraving, micromachining

Combination of CW and pulse

Ideal for spot welding and battery welding

Low power: 20W – 200W

Medium power: 300W – 3000W

High power: 3000W – 60000W

Fiber laser cutting source

Fiber laser welding source

Fiber laser cleaning source

Fiber laser marking source

Fiber laser engraving source

Fiber laser cladding / hardening source

Fiber laser cutting machines are mainly used for metal sheet and tube processing.

Common materials:

Carbon steel

Stainless steel

Aluminum

Brass

Copper

Titanium

Advantages:

Extremely high cutting speed

Narrow kerf width

High precision

Excellent edge quality

Fully CNC controlled

No tool wear

Fiber laser welding machines provide deep penetration, high strength, and minimal deformation.

Applications:

Sheet metal welding

Battery pack welding

Automotive body welding

Handheld laser welding

Jewelry welding

Advantages:

Small heat affected zone

No filler wire required

High welding consistency

Easy robot integration

Suitable for automation lines

Fiber laser cleaning is a green surface treatment technology that replaces chemical and sandblasting methods.

Used for:

Rust removal

Paint stripping

Oil and grease removal

Oxide layer cleaning

Mold cleaning

Surface pre-treatment before welding

Advantages:

Non-contact

No chemicals

No abrasives

Environmentally friendly

No damage to base material

Fiber laser marking machines are used for permanent identification and traceability.

Applications:

Serial numbers

QR codes

Logos

Barcodes

Date codes

Anti-counterfeiting

Advantages:

Permanent marking

High contrast

No ink or consumables

Extremely low maintenance

Long lifespan

Sheet metal fabrication

CNC machining centers

Tool and mold making

Car body cutting

Battery welding

Component marking

PCB marking

Semiconductor packaging

Smartphone components

Surgical instruments

Medical device marking

Titanium cutting

Precision welding

Lithium battery welding

Solar panel processing

Fiber lasers perform poorly on:

Wood

Acrylic

Glass

Fabric

CO₂ lasers are better for non-metals.

Copper, brass, and gold can cause back reflection, potentially damaging the laser source without isolation protection.

High-power systems require:

High capital cost

Skilled operators

Stable power supply

Fiber lasers mainly produce black/gray marks. UV lasers are better for color marking.

Fiber laser machines have become the core equipment of Industry 4.0, replacing traditional mechanical and thermal processing methods.

With advantages such as:

High energy efficiency

Long service life

Low operating cost

High automation compatibility

Excellent processing quality

fiber lasers are now the best industrial solution for metal cutting, welding, cleaning, marking, engraving, and surface treatment.

For companies seeking:

Higher productivity

Lower labor cost

Higher precision

Better product consistency

fiber laser technology is the future of intelligent manufacturing and smart factories.

This is the first one.