Feb 05 , 2026

A laser cutting machine is a high-precision cutting system that uses a focused laser beam to cut, engrave, or mark materials. The laser melts, burns, or vaporizes the material along a programmed cutting path, while assist gas (such as oxygen or nitrogen) blows away molten material for a clean edge.

A laser source (usually fiber laser for metal cutting) generates a high-energy beam

The beam is focused through a cutting head to a very small spot

Intense heat melts or vaporizes the material

CNC control ensures extremely accurate movement

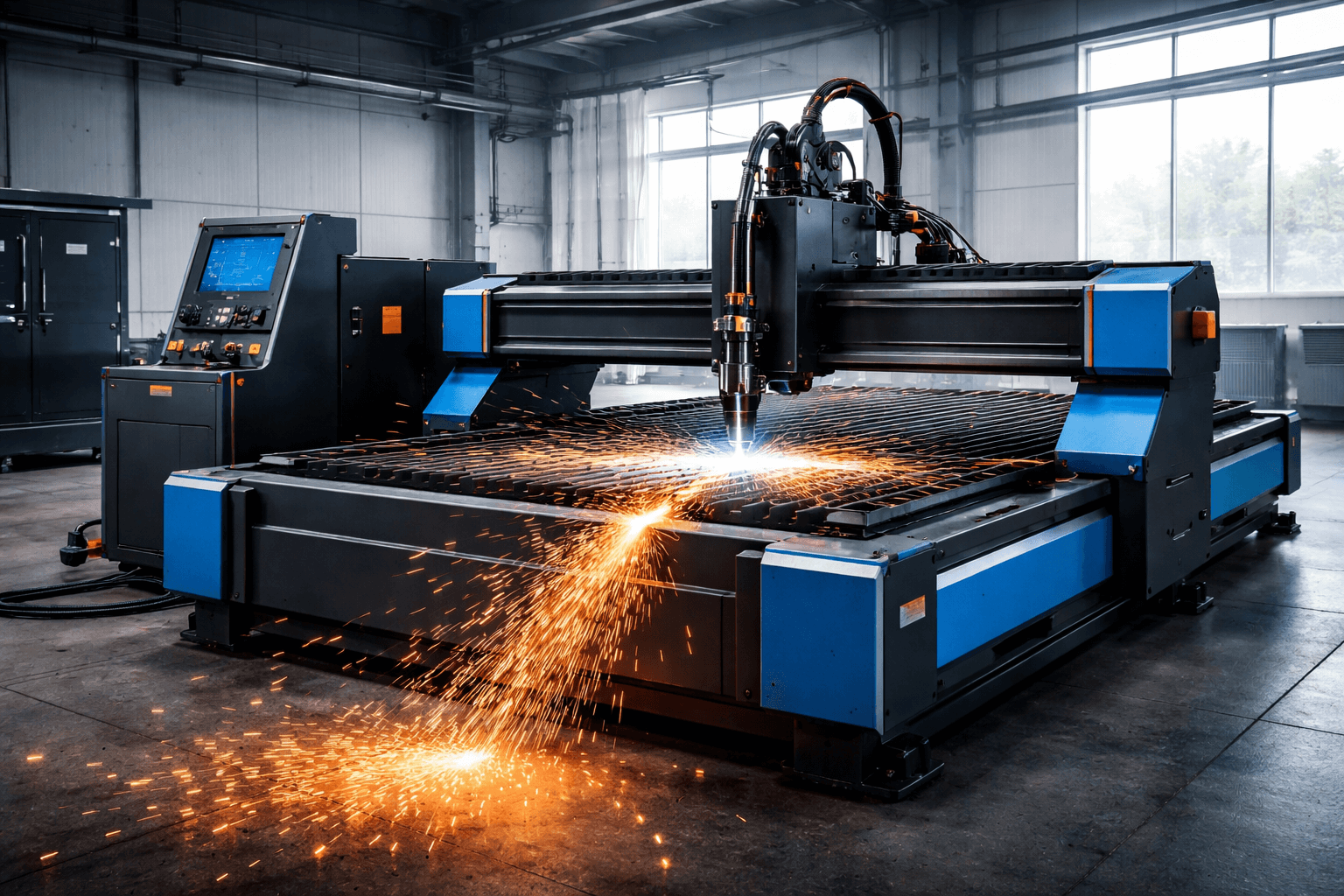

A plasma cutting machine cuts electrically conductive materials by using a high-temperature plasma arc. Plasma is formed when compressed gas (air, oxygen, nitrogen, etc.) is ionized by an electric arc, creating extremely high heat that melts the metal.

Electrical current passes through gas

The gas becomes ionized into plasma

Plasma arc melts the metal

High-speed gas blows molten metal away from the cut

Material | Thickness(mm) | Speed(mm/min) | ||

15KW | 20KW | 300A Plasma | ||

SS | 12 | 7000-7500 | 8500-9000 | 3000 |

14 | 4600-5000 | 6500-7000 | 2670 | |

20 | 1800-2200 | 2000-2500 | 1930 | |

25 | 1100-1500 | 2000-2500 | 1430 | |

30 | 700-900 | 1300-1700 | 1080 | |

40 | 200-350 | 800-1000 | 450 | |

50 | 100-200 | 400-600 | 260 | |

CS | 12 | 6000-7000 | 8500-9000 | 3940 |

15 | 4500-5500(air) | 6500-7000 | 3440 | |

20 | 1500-1600(O2) | 2500-3000(air) | 2500 | |

25 | 1200-1300(O2) | 1900-2000(O2) | 1900 | |

30 | 1100-1200(O2) | 1200-1500(O2) | 1500 | |

Based on the cutting speed comparison above, 15 kW and 20 kW fiber laser cutting machines consistently outperform 300A plasma cutting systems, especially as material thickness increases. For both stainless steel (SS) and carbon steel (CS), high-power laser cutting delivers significantly higher cutting speeds, better stability, and greater process control.

The advantage becomes more pronounced on medium to thick plates (20–50 mm), where 20 kW laser cutting machines show up to 2–3× higher cutting speed than plasma cutting, particularly on stainless steel. Even at thinner thicknesses (12–15 mm), laser cutting maintains a clear speed lead while offering superior cut quality and precision.

Additionally, laser cutting provides greater flexibility with assist gases (air or oxygen), enabling manufacturers to optimize cutting speed, edge quality, and operating cost according to production requirements. Plasma cutting, while still suitable for rough cutting and lower-precision applications, shows clear limitations in speed and efficiency when compared with modern high-power laser technology.

Overall, for manufacturers focused on high productivity, precision cutting, and efficient processing of thick metal plates, investing in a 15 kW or 20 kW fiber laser cutting machine delivers superior performance and long-term production advantages over traditional plasma cutting systems.

Item | Laser cutting(20kw) | Plasma cutting |

Machine investment cost(*10,000) | 100 | 50 |

Working Hours(Year) | 4500(15H/2Shifts/D, 300D/Y) | 4500 |

Spare parts(RMB/H) | 5 | 70 (Electrodes, nozzles, swirl rings, trays, etc.) |

Machine depreciation(5Years, RMB/H) | 45 | 22 |

Average Electric consumption(RMB/H) | 80 | 80 |

N2 consumption(RMB/H) | 0 | 12 |

Loading(1person) Polishing(2Persons) | 0 | 60 |

Drilling, transport etc.(3 persons/machine) | 0 | 60 |

Fixed cost (RMB/H) | 130 | 304 |

Cutting speed (20MM SS) | 3000mm/min. | 1900mm/min. |

Running Cost/M | 130/60/3.0m=0.72RMB/M | 304/60/1.9m=2.67RMB/M |

Cutting speed(40mm SS) | 1000mm/min. | 450mm/min. |

Running Cost/m | 263/60/1m=2.16RMB/M | 304/60/0.45m=11.3RMB/M |

Although the initial investment cost of a 20 kW laser cutting machine is significantly higher than that of a plasma cutting machine, the actual operating cost per meter is much lower, particularly when cutting medium and thick stainless steel.

From the data, laser cutting eliminates many hidden production costs associated with plasma cutting, including consumable spare parts, manual polishing, drilling, and material handling labor. As a result, the fixed hourly cost of laser cutting (130 RMB/h) is already lower than plasma cutting (304 RMB/h), despite the higher machine depreciation.

More importantly, due to the much higher cutting speed, the running cost per meter for laser cutting is dramatically reduced:

At 20 mm stainless steel, laser cutting costs 0.72RMB/m, compared to 2.67 RMB/m for plasma cutting (≈27% cost reduction).

At 40 mm stainless steel, laser cutting costs 2.16 RMB/m, while plasma cutting reaches 11.3 RMB/m (≈19% cost reduction).

In addition to cost savings, laser cutting offers higher efficiency, better cut quality, and zero secondary processing, which further improves production stability and delivery speed.

Item | Laser cutting(20kw) | Plasma cutting |

Machine investment cost(*10,000) | 100 | 50 |

Working Hours(Year) | 4500(15H/2Shifts/D, 300D/Y) | 4500 |

Spare parts(RMB/H) | 5 | 70 (Electrodes, nozzles, swirl rings, trays, etc.) |

Machine depreciation(5Years, RMB/H) | 45 | 22 |

Average Electric consumption(RMB/H) | 80 | 80 |

N2 consumption(RMB/H) | (10 @thickness>20mm) | 12 |

Loading(1person) Polishing(2Persons) | 0 | 60 |

Drilling, transport etc.(3 persons/machine) | 0 | 60 |

Fixed cost (RMB/H) | 140 | 304 |

Cutting speed (20MM SS) | 7000mm/min. | 3400mm/min. |

Running Cost/M | 140/60/7m=0.33RMB/M | 304/60/3.4m=1.49RMB/M |

Cutting speed(40mm SS) | 1500mm/min. | 1500mm/min. |

Running Cost/m | 140/60/1.5m=1.5RMB/M | 304/60/1.5m=3.38RMB/M |

The data shows that 20 kW laser cutting delivers significantly lower operating cost per meter than plasma cutting, even though the laser system requires a higher initial investment. When cutting 20 mm stainless steel, laser cutting achieves a much higher speed (7,000 mm/min vs 3,400 mm/min), resulting in a running cost of only 0.33 RMB/m, compared to 1.49 RMB/m for plasma cutting, representing a cost reduction of more than 60%.

For 40 mm stainless steel, both technologies reach similar cutting speeds (1,500 mm/min). However, due to lower labor requirements, fewer consumables, and reduced post-processing, laser cutting still maintains a lower running cost of 1.5 RMB/m, compared to 3.38 RMB/m for plasma cutting. Even when additional nitrogen consumption is considered for thicker plates, the overall cost advantage of laser cutting remains clear.

Furthermore, laser cutting eliminates manual polishing, drilling, and secondary handling, which significantly reduces labor dependency and improves production consistency. While plasma cutting benefits from lower machine investment, its higher consumable usage, labor costs, and slower cutting speed lead to higher long-term operating expenses.

Parameters | Fiber Laser | Plasma |

Positioning precision | 0.14mm/10m | 0.4mm/10m |

Repeated positioning speed | 0.05mm/10m | 0.2mm/10m |

Surface verticality | <0.8° | 2° |

Kerf Width | 0.2-2mm | 0.6-5.0mm |

Heat affected area | 0.1-0.4mm | 0.5-2.0mm |

Surface quality | Good, less dross | Normal, lots of dross |

The comparison clearly shows that laser cutting machines outperform plasma cutting systems in precision, cut quality, and thermal control. Laser cutting offers significantly higher positioning and repeat positioning accuracy, ensuring stable and consistent results for high-precision manufacturing. The smaller kerf width and much narrower heat-affected zone produced by laser cutting reduce material loss and minimize thermal deformation.

In addition, laser cutting delivers better surface verticality and cleaner cut edges with minimal dross, eliminating or greatly reducing the need for secondary processing such as grinding or polishing. By contrast, plasma cutting produces wider kerfs, larger heat-affected areas, and heavier dross, making it more suitable for rough cutting applications where high accuracy and surface quality are not critical.

Thickness | Intended size A | |||||||

0<A<3 | 3≤A<10 | 10≤A<25 | 25≤A<125 | 125≤A<315 | 315≤A<1000 | 1000≤A<2000 | 2000≤A<4000 | |

limit deviation | ||||||||

0<t≤1 | ±0.04 | ±0.1 | ±0.1 | ±0.2 | ±0.2 | ±0.3 | ±0.3 | ±0.3 |

1<t≤3.15 | ±0.1 | ±0.2 | ±0.2 | ±0.3 | ±0.3 | ±0.4 | ±0.4 | ±0.4 |

3.15<t≤6.3 | ±0.3 | ±0.3 | ±0.4 | ±0.4 | ±0.5 | ±0.5 | ±0.5 | ±0.6 |

6.3<t≤10 | ±0.5 | ±0.6 | ±0.6 | ±0.7 | ±0.7 | ±0.7 | ±0.78 | |

10<t≤50 | ±0.6 | ±0.7 | ±0.7 | ±0.8 | ±1 | ±1 | ±2.5 | |

Thickness | Intended size A | |||||||

0<A<3 | 3≤A<10 | 10≤A<25 | 25≤A<125 | 125≤A<315 | 315≤A<1000 | 1000≤A<2000 | 2000≤A<4000 | |

limit deviation | ||||||||

0<t≤1 | ±0.02 | ±0.03 | ±0.05 | ±0.1 | ±0.1 | ±0.15 | ±0.15 | ±0.15 |

1<t≤3.15 | ±0.05 | ±0.07 | ±0.1 | ±0.15 | ±0.15 | ±0.2 | ±0.2 | ±0.2 |

3.15<t≤6.3 | ±0.15 | ±0.1 | ±0.2 | ±0.2 | ±0.25 | ±0.25 | ±0.25 | ±0.3 |

6.3<t≤10 | ±0.17 | ±0.3 | ±0.3 | ±0.35 | ±0.35 | ±0.35 | ±0.4 | |

10<t≤50 | ±0.2 | ±0.35 | ±0.35 | ±0.4 | ±0.5 | ±0.5 | ±1.25 | |

The 20 kW laser cutting machine has significantly higher cutting accuracy (tighter tolerances) than the 300 A plasma cutting machine across all thicknesses and part sizes.

| Machine | Typical tolerance range |

|---|---|

| 300A Plasma | ±0.1 mm to ±2.5 mm |

| 20kW Laser | ±0.02 mm to ±1.25 mm |

Laser is about 2–5× more accurate than plasma.

Plasma: ±0.04 to ±0.4 mm

Laser: ±0.02 to ±0.2 mm

Laser is roughly twice as precise for thin sheet metal.

Plasma: ±0.3 to ±0.78 mm

Laser: ±0.1 to ±0.4 mm

Laser still ~2× better dimensional control.

Plasma: ±0.6 to ±2.5 mm

Laser: ±0.2 to ±1.25 mm

On heavy plates, plasma deviation becomes very large,

while laser remains relatively stable.

Precision parts

Assemblies requiring tight fit

Aerospace / automotive components

CNC machining pre-cut blanks

High-end fabrication

Rough cutting

Structural steel

Shipbuilding

Construction frames

When speed & cost matter more than accuracy

| Factor | Plasma | Laser |

|---|---|---|

| Accuracy | Low–Medium | High |

| Kerf width | Wide | Narrow |

| Heat affected zone | Large | Small |

| Post machining needed | Often | Minimal |

| Edge quality | Rough | Clean |

| Precision assembly | ❌ | ✅ |

You can confidently state:

20kW laser cutting provides 2–5 times higher dimensional accuracy than 300A plasma cutting, especially critical for precision manufacturing and high-value components.

This chart strongly supports positioning laser as a premium, high-precision solution, and plasma as a cost-effective heavy-duty solution.

| Item | High Power Laser Cutting Machine | Plasma Cutting | Advantages of High Power Laser Cutting |

|---|---|---|---|

| Positioning Precision | ±0.14 mm / 10 m | ±0.4 mm / 10 m | Much higher positioning accuracy |

| Section Perpendicularity | ≤0.2 mm / 40 mm | ≤5 mm / 40 mm | No need for secondary machining |

| Kerf Width (Cutting Gap) | 0.2 – 1.5 mm | 2.0 – 5.0 mm | Less material removal |

| Material Utilization | High | Low | Material saving of approx. 5–8% |

| Minimum Borderline / Common Edge | 3 – 4 mm | ≥10 mm | Higher nesting efficiency |

| Heat Affected Zone (HAZ) | 0.1 – 0.4 mm | 0.5 – 2.0 mm | Low heat absorption, minimal deformation |

| Cut Section Quality | Excellent, very little slag | Normal, heavy slag | No grinding or polishing required |

| Cutting Speed (20 mm Carbon Steel) | Fast | Normal | Higher productivity and efficiency |

| Small Hole Capability | Hole diameter to thickness ratio: 10–20% | Not suitable | No drilling or secondary processing |

| Bevel Cutting | Supported | Generally not supported | No secondary bevel processing |

| Working Environment | Clean, low smoke | Heavy smoke and dust | Environmentally friendly |

A high power laser cutting machine significantly outperforms plasma cutting in terms of precision, cut quality, material utilization, and production efficiency. Laser cutting delivers much higher positioning accuracy, smaller kerf width, and a minimal heat-affected zone, resulting in cleaner cut edges, less deformation, and little to no need for secondary machining.

In addition, laser cutting enables higher nesting efficiency, better material savings (approximately 5–8%), and the ability to process small holes and bevel cuts directly, which plasma cutting generally cannot achieve. The cleaner working environment with low smoke and dust also makes laser cutting more environmentally friendly and suitable for modern automated factories.

By contrast, plasma cutting remains suitable for rough cutting of thick metal where ultra-high precision is not required, but it produces wider kerfs, larger heat-affected zones, heavier slag, and typically requires additional post-processing.

High power fiber laser cutting machines provide a significant technological advantage over traditional plasma cutting machines. Compared with plasma cutting systems, laser cutting machines offer much higher positioning precision, smaller kerf width, lower heat affected zone, and cleaner cut edges. In addition, laser cutting delivers 2–3 times higher cutting speed on medium and thick metal plates, especially for stainless steel and carbon steel applications.

From a cost perspective, although the initial investment of a laser cutting machine is higher, the actual operating cost per meter is substantially lower due to reduced consumable usage, lower labor requirements, and minimal post-processing. As a result, high power laser cutting machines achieve faster return on investment (ROI) and better long-term profitability.

For manufacturers focused on high efficiency, precision cutting, automated production, and high-quality metal fabrication, high power fiber laser cutting machines are the optimal replacement for plasma cutting machines in modern industrial environments.

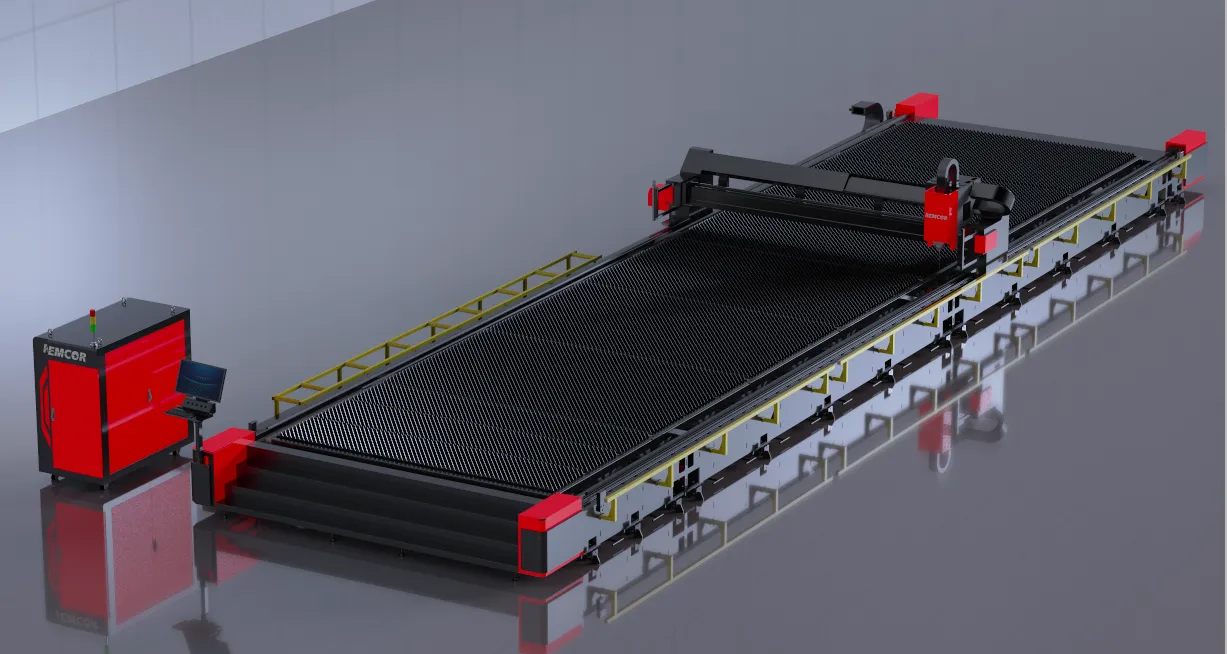

This is the first one.