Jan 30 , 2023

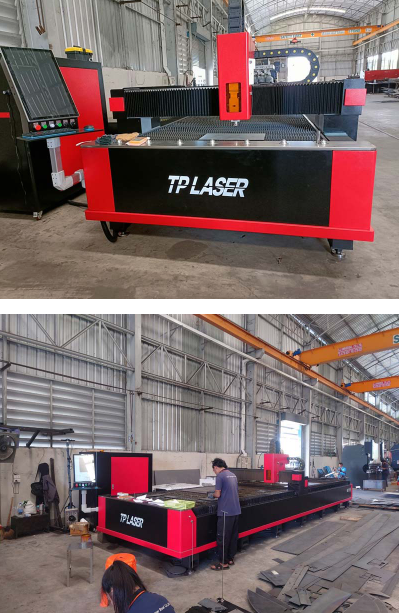

The first fiber laser cutting machine purchased by this customer was installed one year ago. It was a 6000W laser cutting machine, commissioned and optimized by our professional engineering team. From the very first day of production, the machine delivered sharp, clean, and beautiful cutting results.

Since then, we have truly grown together with our customer. We firmly believe that without reliable product quality and professional after-sales service, long-term cooperation is impossible. Quality and service are always the foundation of our success.

The first installation was a 6000W fiber laser cutting machine equipped with:

Exchangeable working tables

Pipe cutting attachment

High-speed laser cutting head

9 mm steel: 3300 mm/min

12 mm steel: 2000 mm/min

16 mm steel: 1700 mm/min

Cutting speed is faster than or equivalent to some 12,000W laser cutting machines from major brands

High-speed cutting head:

Optimized for thin metal cutting with higher speed and smoother edges

Capable of cutting thick metal efficiently as well

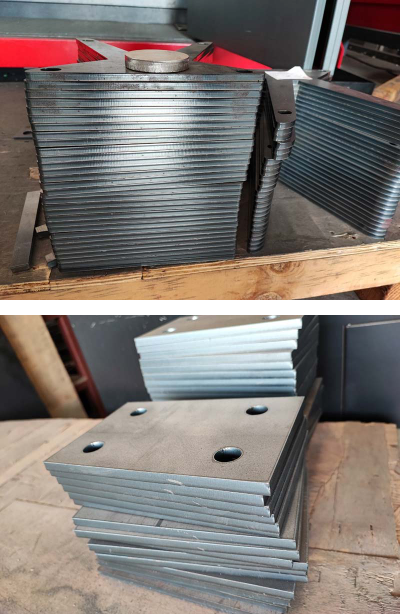

Thick plate cutting results:

Smooth cutting edge

Full penetration

Minimal heat influence and no overheating

This 6000W laser cutting machine proves that excellent machine design and parameter optimization can outperform higher-power systems.

The second investment was a 3000W fiber laser cutting machine (6015 working area).

We were delighted to see the customer’s satisfaction and confidence after the installation.

Excellent mechanical structure

Smooth and stable machine operation

Durable design for long-term industrial use

Ideal solution for most sheet metal applications

This 3kW laser cutting machine is well known as the best cost-performance model, covering the majority of daily cutting requirements.

The third machine is a 2000W fiber laser cutting machine with a 4020 working table, designed for flexible and economical production.

Machine operation is extremely smooth and quiet

Compact structure, easy to move and arrange in the workshop

Excellent cutting quality at a reasonable and competitive price

We clearly explain to customers that:

Cheap machines with light bodies and small motors will show clear differences in stability and cutting precision

Our laser cutting machine focuses on:

Better structural design

Higher machining accuracy

Long-term reliability

Beyond the fiber laser cutting machine itself, our value lies in our service philosophy.

Free on-site commissioning and optimization

Free operator training and technical guidance

Free experience sharing and application improvement

Continuous support to help customers fully understand and utilize the machine

Our engineers provide training without additional labor charges, because:

Solving customer problems is our responsibility

Helping customers succeed is our mission

We are happy to invest our time and expertise if it means seeing customers satisfied and smiling.

Remcor is not only a laser cutting machine manufacturer, but a long-term partner.

With:

High-quality fiber laser cutting machines

Competitive performance at each power level

Professional and responsible service

We help customers achieve:

Higher efficiency

Better cutting quality

Sustainable growth