Nov 07 , 2025

Laser Cleaning Machine vs. Traditional Cleaning Methods — Professional Comparison

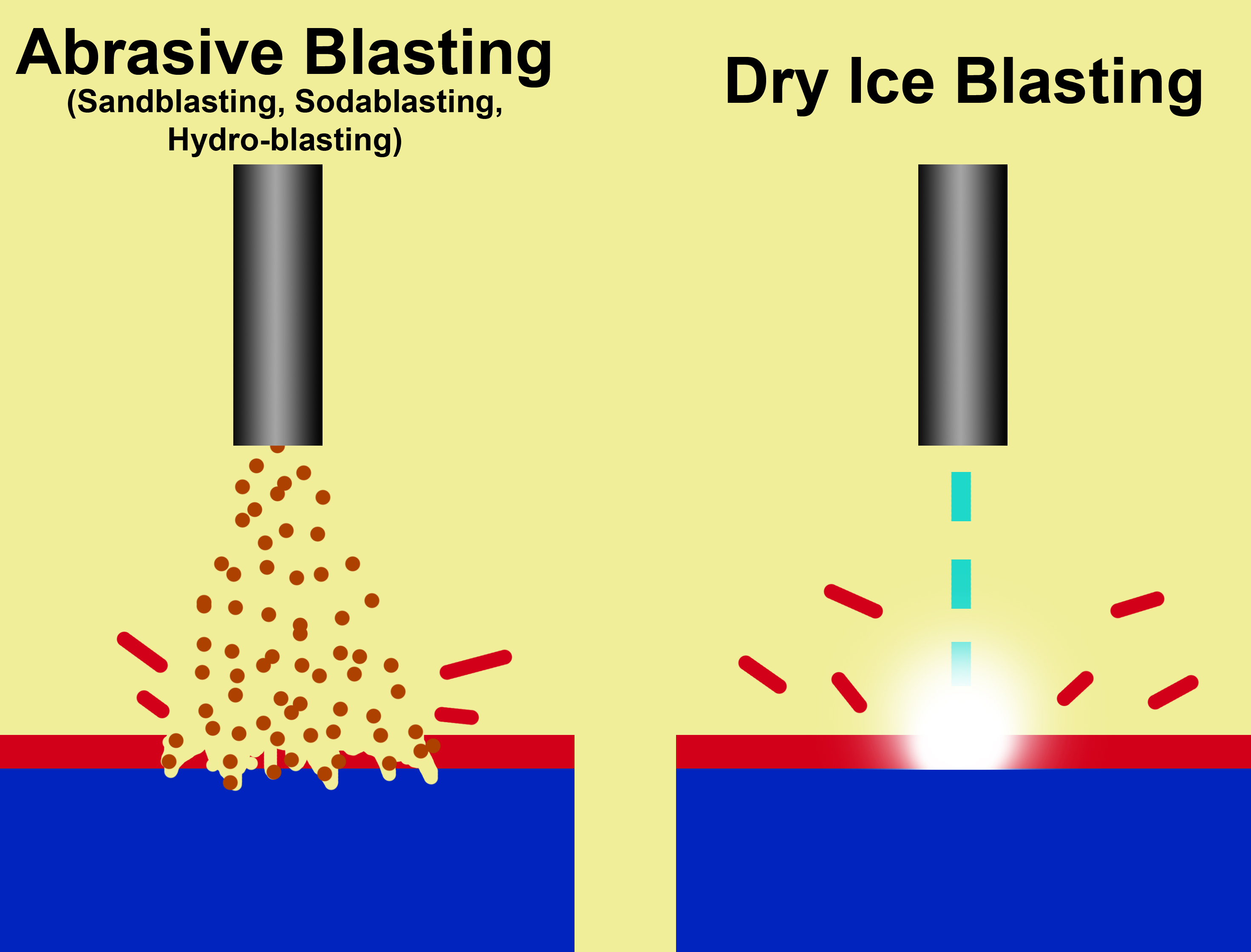

The laser cleaning machine is a cutting-edge technology for surface treatment, rust removal, and paint stripping. Compared with traditional methods such as dry ice blasting, sandblasting, and chemical cleaning, laser cleaning offers a more sustainable and precise solution. However, each method has its own strengths and limitations. This article provides a professional comparison to help industries choose the most suitable cleaning technology.

1. Initial Cost of Investment

The initial investment for a laser cleaning machine is higher than for conventional cleaning systems. A quality air cooling laser cleaning machine or water cooling laser cleaning machine requires advanced laser sources and control systems, resulting in higher upfront costs.

However, since the laser cleaner uses no consumables such as dry ice or chemicals, the long-term operating cost is significantly lower, offering a better return on investment over time.

2. Operator Experience

A laser cleaning system requires a trained operator who understands key parameters such as pulse frequency, focus distance, and scan speed. While traditional cleaning methods can be used with minimal experience, laser cleaning machines deliver higher precision and repeatability when handled by a skilled technician.

3. Safety Concerns

Laser cleaning involves high-intensity laser beams that can be hazardous if used improperly. Proper laser safety measures—including protective eyewear and enclosed work zone are essential.

In contrast, dry ice blasting or chemical cleaning presents different risks such as flying debris or toxic fumes. Modern handheld laser cleaning machines now feature built-in safety sensors, interlocks, and protective covers to ensure operator safety.

4. Environmental Considerations

Laser cleaning technology is among the most eco-friendly cleaning solutions available today. It generates no secondary waste, water contamination, or chemical residue.

Dry ice blasting releases CO₂ gas, while chemical cleaning produces hazardous waste that requires special disposal. A laser cleaning machine only produces microscopic dust, which can be easily collected with an integrated fume extraction system.

5. Limited Use Areas

Laser cleaning is most effective on direct line-of-sight surfaces. Curved, shaded, or highly uneven areas can reduce cleaning efficiency.

However, the latest portable laser cleaning machines and backpack laser cleaners with adjustable scanning heads now allow easier operation in complex work environments, such as industrial maintenance and outdoor equipment cleaning.

6. Cleaning Efficiency

For thick coatings or heavy rust, abrasive blasting or dry ice blasting can sometimes clean faster.

Yet, laser cleaning machines excel in precision surface cleaning—removing contaminants layer by layer without damaging the base material. For industries like aerospace, automotive, and mold manufacturing, this precision is a major advantage.

7. Material Limitations

Highly reflective materials such as aluminum or copper can reduce laser absorption efficiency, requiring fine parameter tuning.

Nevertheless, with the right fiber laser cleaning machine, it is possible to achieve consistent and stable cleaning results across a wide range of metals, including stainless steel, carbon steel, and titanium.

8. Parameter Optimization

The cleaning performance of a laser cleaning system depends on optimized settings such as power, pulse width, and scan speed. Incorrect parameters can reduce effectiveness.

However, our laser cleaners come equipped with automatic parameter presets and real-time adjustment software, making operation easier for users of all levels.

9. Cleaning Stability

Environmental factors like humidity, temperature, and surface reflectivity can slightly influence laser cleaning stability.

However, the latest air cooling and water cooling laser cleaning machines are designed with stable laser output, ensuring consistent performance in different working environments.

10. Electricity Consumption

Compared to mechanical or chemical cleaning methods, laser cleaning machines consume more electrical energy, especially high-power industrial models.

However, air cooling laser cleaning machines offer better energy efficiency and lower maintenance costs compared with water cooling systems, making them ideal for mobile or outdoor use.

Advantages of the Handheld Laser Cleaning Machine

Despite certain disadvantages, the handheld laser cleaning machine provides multiple benefits that make it increasingly popular for industrial and field cleaning applications:

• Non-contact cleaning: No mechanical stress or abrasion on the substrate.

• No consumables: Eliminates sand, dry ice, and chemical waste.

• Environmentally safe: 100% green cleaning process with no secondary pollution.

• High precision: Accurate control of cleaning depth and area.

• Portable and flexible: Suitable for on-site maintenance and aerial work.

• Low maintenance: Long service life and stable laser output.

• Multi-material compatibility: Effective for metals, molds, welding seams, and painted surfaces.

Conclusion

While the laser cleaning machine has higher initial costs and requires trained operation, its eco-friendly nature, precision cleaning ability, and long-term cost efficiency make it the most promising technology for modern surface treatment.

Once have the cleaning requirement, we need to understand the basic information about the different cleaning ways and follow the strict requirement, then we can to maximum different way of the cleaning

Remcor Technology, as a professional manufacturer of air cooling laser cleaning machines, water cooling laser cleaning machines, and handheld portable laser cleaners, continues to develop high-performance systems that meet global industrial cleaning standards.