Nov 18 , 2025

3000W Laser Cutting machine(50μm) | ||||||||

Material |

T (mm) |

Speed (m/min) |

Power(W) |

Gas |

Pressure (bar) |

Nozzle (mm) | Focus(mm) | Cutting height(mm) |

CS | 1 | 35-40 |

3000 | N2/ Air | 10 | 2.0 S | 0 | 0.6 |

2 | 20-25 | 10 | 2.0 S | -1 | 0.6 | |||

2 | 5.0-6.0 | 3000 |

O2 | 1.5 | 1.0 D | +3 | 0.6 | |

3 | 3.5-4.5 | 3000 | 0.8 | 1.0 D | +4 | 0.6 | ||

4 | 3.2-4.0 | 3000 | 0.8 | 1.0 D | +5 | 0.6 | ||

5 | 3.0-3.5 | 3000 | 0.8 | 1.0 D | +6 | 0.6 | ||

6 | 2.5-3.0 | 3000 | 0.8 | 1.0 D | +7 | 0.6 | ||

8 | 2.0-2.3 | 3000 | 0.8 | 1.2 D | +7 | 0.6 | ||

10 | 1.4-1.8 | 3000 | 0.8 | 1.2 D | +5 | 0.6 | ||

12 | 1.2-1.4 | 3000 | 0.8 | 4.0 D | +4 | 0.6 | ||

14 | 0.8-0.9 | 2600 | 0.8 | 4.0 D | +4 | 1.0 | ||

16 | 0.7-0.9 | 2600 | 0.6 | 4.0 D | +4 | 1.0 | ||

18 | 0.65-0.75 | 2400 | 0.6 | 4.0 D | +4 | 1.0 | ||

20 | 0.6-0.7 | 2400 | 0.6 | 5.0 D | +4.5 | 1.0 | ||

22 | 0.5-0.6 | 2400 | 0.6 | 5.0 D | +4.5 | 1.0 | ||

SS | 1 | 45-55 | 10 | 2.0 S | 0 | 0.5 | ||

2 | 24-28 | 10 | 2.0 S | -0.5 | 0.5 | |||

3 | 8-13 |

3000 |

N2 | 12 | 3.0 S | -1 | 0.5 | |

4 | 5-6 | 14 | 3.0 S | -1.5 | 0.5 | |||

5 | 3-4 | 15 | 3.0 S | -3 | 0.5 | |||

6 | 2.3-3.0 | 16 | 3.0 S | -4 | 0.5 | |||

8 | 1.0-1.5 | 16 | 4.0 S | -5 | 0.5 | |||

10 | 0.8-1.0 | 18 | 4.0 S | -7 | 0.5 | |||

Aluminium | 1 | 40-50 |

3000 |

N2 | 10 | 2.0 S | 0 | 0.6 |

2 | 15-20 | 10 | 2.0 S | -0.5 | 0.5 | |||

3 | 8-10 | 12 | 3.0 S | -1 | 0.5 | |||

4 | 4-5 | 14 | 3.0 S | -2 | 0.5 | |||

5 | 2.5-3.5 | 16 | 3.0 S | -3 | 0.5 | |||

6 | 2.0-2.3 | 16 | 3.0 S | -4 | 0.5 | |||

8 | 0.8-1.3 | 16 | 3.5 S | -5 | 0.5 | |||

Copper | 1 | 25-28 |

3000 |

N2 | 10 | 2.0 S | 0 | 0.5 |

2 | 13-15 | 10 | 2.0 S | -1 | 0.5 | |||

3 | 5.0-6.0 | 12 | 3.0 S | -1 | 0.5 | |||

4 | 2.5-3.0 | 12 | 3.0 S | -2 | 0.5 | |||

5 | 1.8-2.3 | 13 | 3.5 S | -2.5 | 0.5 | |||

6 | 1.0-1.3 | 14 | 4.5 S | -3 | 0.5 | |||

Brass | 1 | 25-28 |

3000 |

O2 | 12 | 3.0 S | -1 | 0.5 |

2 | 8.0-10 | 12 | 3.0 S | -1 | 0.5 | |||

3 | 3.0-4.5 | 13 | 3.0 S | -2 | 0.5 | |||

4 | 2.0-2.5 | 14 | 3.5 S | -4 | 0.5 | |||

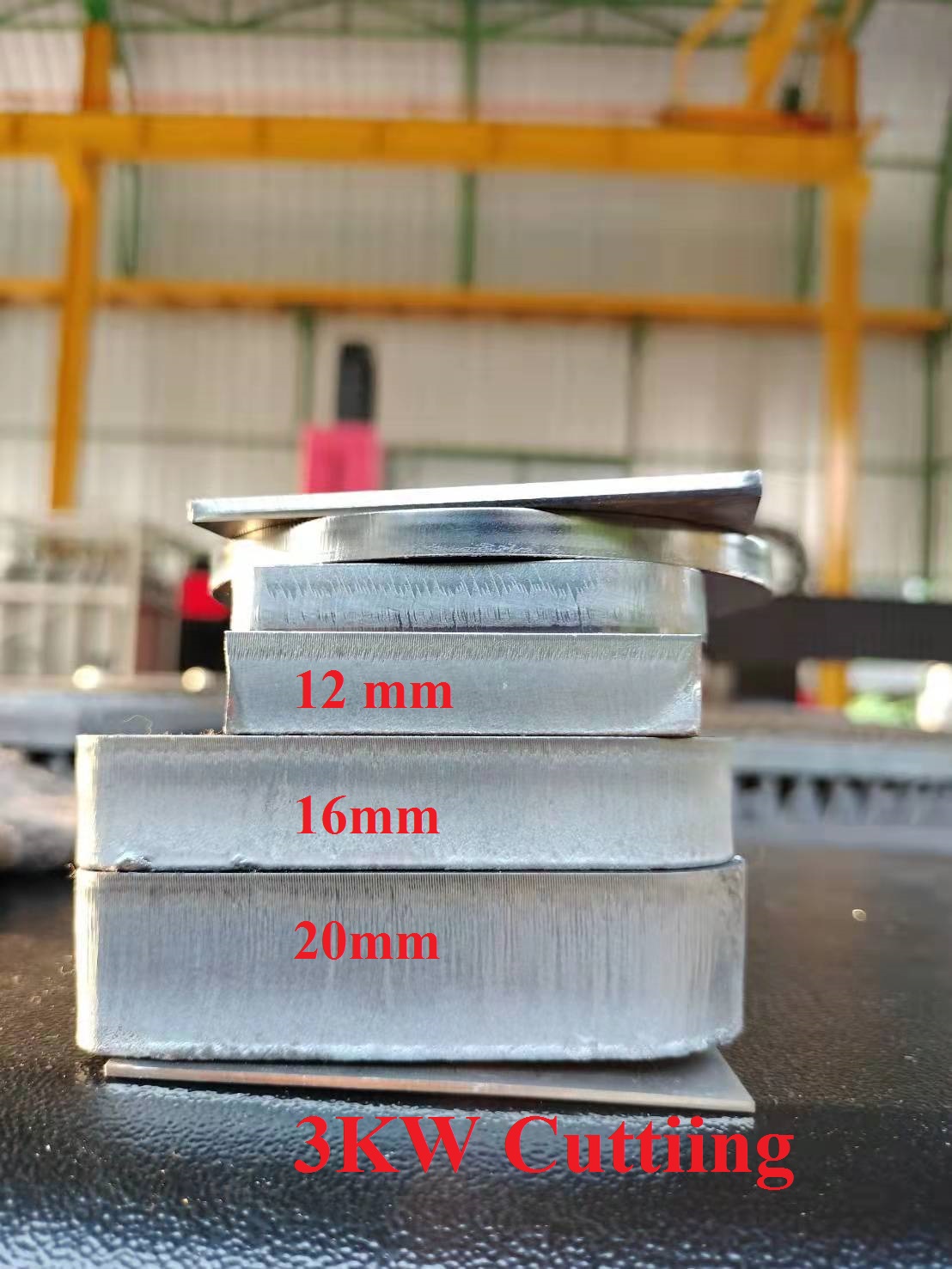

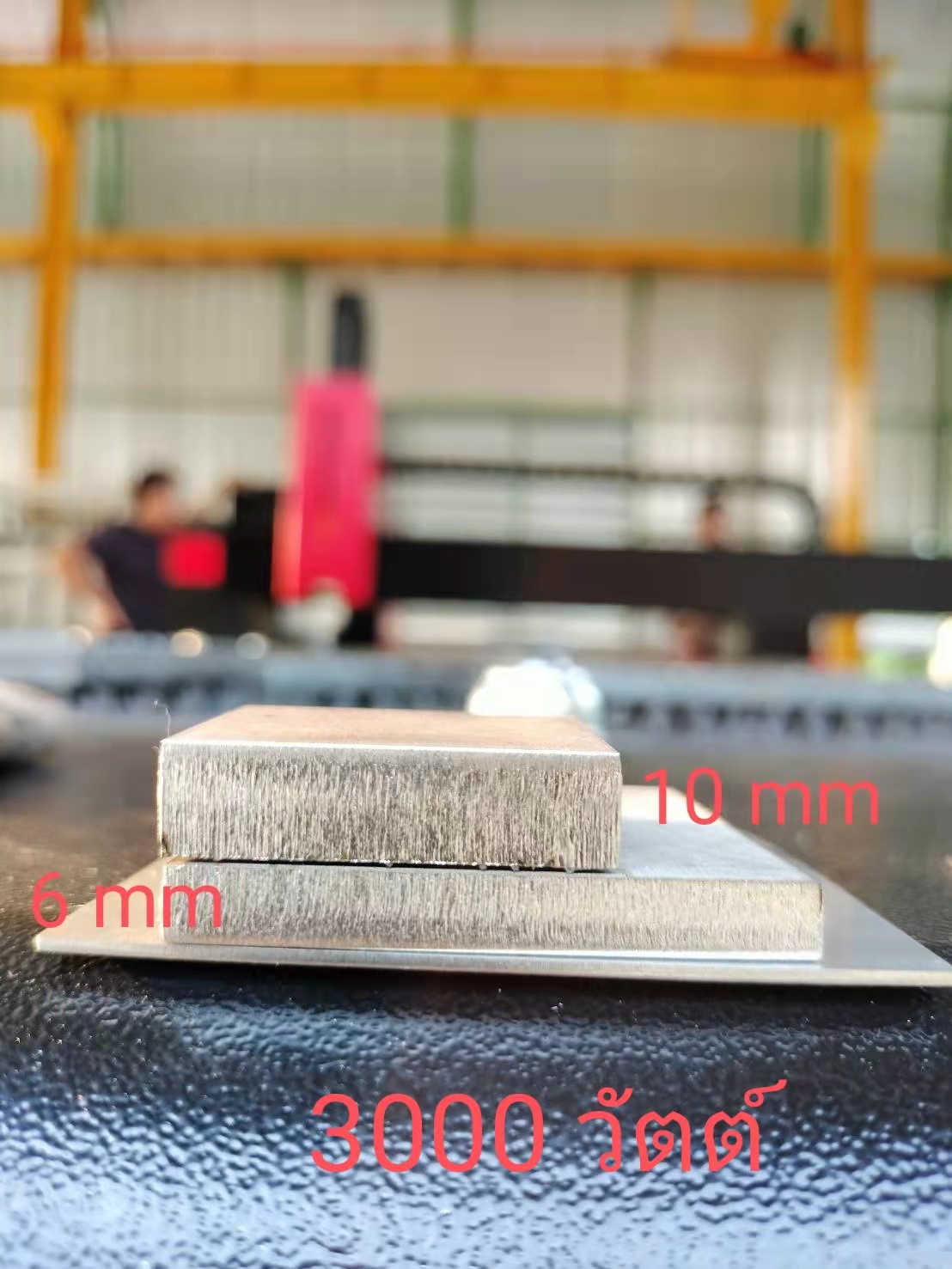

A 3000W fiber laser cutting machine sits at the ideal balance point between cutting performance, cost efficiency, and operational stability. Across metal fabrication, automotive parts production, signage, HVAC, and general manufacturing, 3000W systems are widely recognized for their high precision, clean edges, and outstanding energy efficiency. As a leading laser-equipment manufacturer, Remcor Technology continues to optimize fiber laser cutting solutions to deliver superior cutting depth, speed, and quality for a wide range of materials.

This above cutting parameters provides a professional breakdown of the cutting thickness capabilities of a 3000W fiber laser cutting machine, as well as the factors influencing cutting depth and the optimal parameter settings for best performance.

A fiber laser 3000w provides a strong and concentrated beam suitable for clean cutting of carbon steel.

Max cutting thickness (with oxygen): 20–22 mm

Recommended high-quality cut: 1-10mm

Oxygen serves as an assist gas, allowing for deeper penetration but creating slightly more oxidation on the edge. The cut remains structurally solid and suitable for most industrial applications.

Aluminum reflects more laser energy and has high thermal conductivity, which typically reduces achievable thickness, but 3000W systems still perform excellently.

Max cutting thickness (with nitrogen): 6–8 mm

Recommended high-quality cut: 1–4 mm

Nitrogen ensures a bright, oxide-free edge, ideal for precision fabrication, aerospace components, and decorative aluminum panels.

Stainless steel responds extremely well to fiber laser cutting due to its lower reflectivity and better absorption characteristics.

Max cutting thickness (with nitrogen): 8–10 mm

Recommended high-precision cut: 1–4mm

A 3000W fiber laser cutting machine running with nitrogen produces a smooth, non-oxidized, burr-free edge. This level of quality is widely appreciated in food-processing equipment, medical device frames, architecture, and high-finish metal parts.

Max cutting thickness: 3–4 mm

Brass is reflective, but modern fiber laser sources with anti-reflection protection—such as those used in Remcor Technology machines—enable stable and precise cutting.

Max cutting thickness: 2–3 mm

Copper’s reflectivity and thermal conductivity limit thickness, but fiber lasers still produce clean contours for busbars, electrical components, and precision parts.

Max cutting thickness: 10–12 mm

Nitrogen or air can be used depending on edge-quality requirements.

Fiber lasers are not recommended for most non-metallic materials. CO₂ systems are usually more appropriate. However, some engineered plastics can be processed in special cases.

Several technical parameters and environmental conditions influence the real-world cutting thickness of a 3000W fiber laser cutting system:

Oxygen increases penetration but leaves oxide edges.

Nitrogen delivers high-quality, oxidation-free edges but requires higher gas pressure.

Air is cost-effective for medium-thickness cuts.

Machines designed by Remcor Technology use high-stability fiber laser generators, ensuring consistent beam quality and deeper, cleaner cuts.

Correct nozzle selection and stable gas flow are essential for cutting thicker metals.

The focal point must be precisely adjusted to maximize energy density at the material surface.

Rust, oil, and coatings may affect cut depth and edge quality.

Slower speeds increase penetration but may reduce edge finish if too slow.

Assist Gas: Oxygen

Gas Pressure: 0.5–1.0 bar

Best Practice: Increase pierce time and optimize focus for smoother edges.

Assist Gas: Nitrogen (99.999% purity recommended)

Gas Pressure: 12–18 bar

Best Practice: Use a small-focus spot for high-precision, burr-free edges.

Assist Gas: Nitrogen

Gas Pressure: 15–20 bar

Best Practice: Keep cutting speed stable and avoid excessive heat input.

Assist Gas: High-pressure nitrogen

Use anti-reflection protection to protect the laser source.

The CNC cutting software and real-time monitoring systems used by Remcor Technology help operators automatically maintain the optimal settings for thickness, material type, and cutting speed.

Remcor Technology, one of top cnc laser cutter factory specializes in professional metal fabrication solutions—including fiber laser cutting machines, laser welding equipment, and laser cleaning systems.

Our 3000W fiber laser cutting platforms offer:

High-precision cutting with industry-leading laser sources

Efficient cooling systems for stable long-duration cutting

Intelligent control systems for automatic parameter optimization

Strong machine frames ensuring zero vibration during high-speed cutting

Long service life and low operation cost

For factories aiming to improve precision, efficiency, and versatility in metal processing, Remcor Technology provides reliable, professional laser solutions engineered for long-term performance